PDF(9611 KB)

PDF(9611 KB)

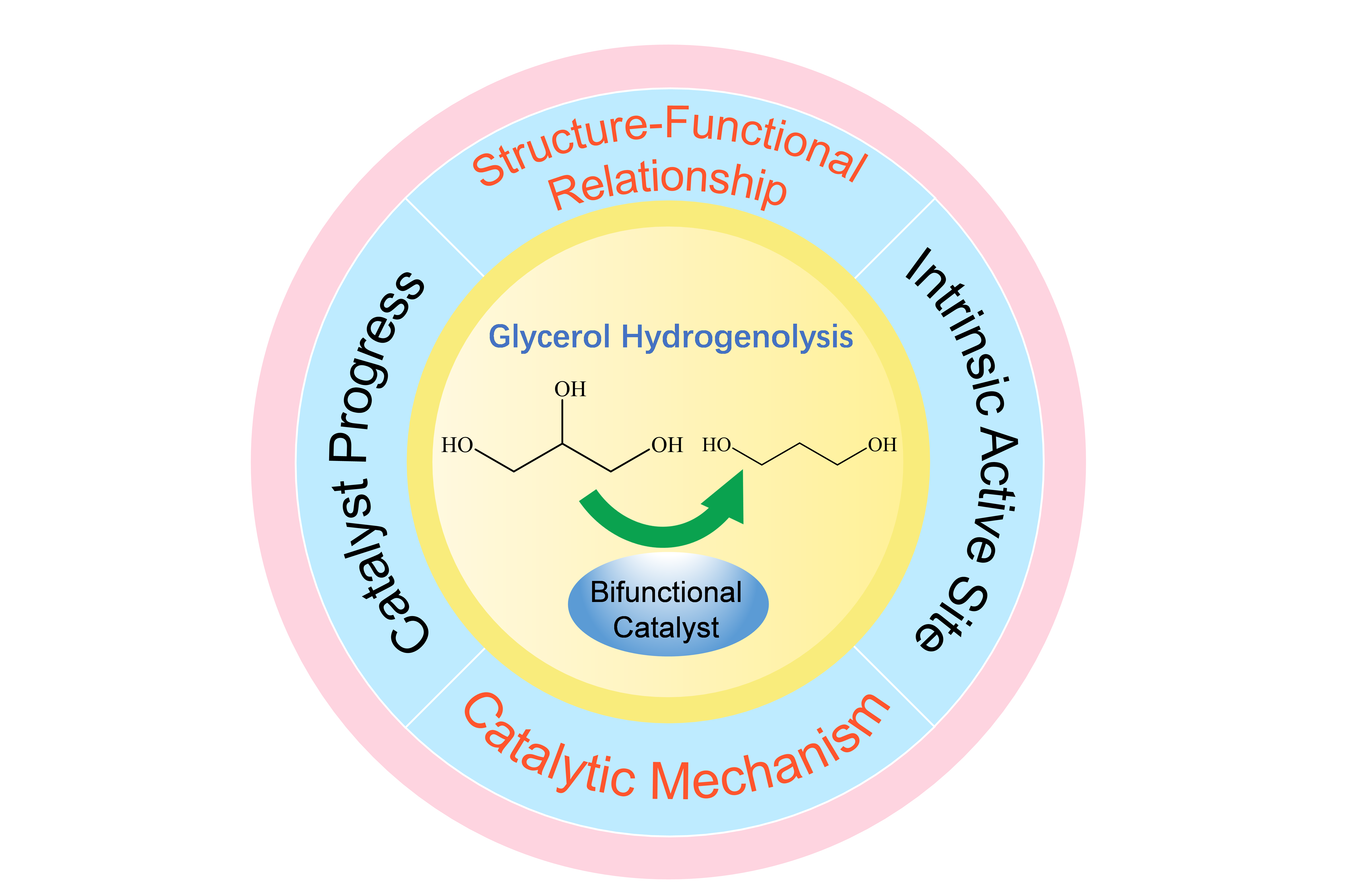

Directed Preparation of 1,3-Propanediol From Glycerol Via Chemoselective Hydrogenolysis Over Bimetallic Catalyst: Active Sites, Structure-Functional Relationship and Mechanism

Man Yang, Yuxiang Jiao, Yujing Ren

Prog Chem ›› 2024, Vol. 36 ›› Issue (2) : 256-270.

PDF(9611 KB)

PDF(9611 KB)

PDF(9611 KB)

PDF(9611 KB)

Directed Preparation of 1,3-Propanediol From Glycerol Via Chemoselective Hydrogenolysis Over Bimetallic Catalyst: Active Sites, Structure-Functional Relationship and Mechanism

1,3-propanediol is one of the most important monomers in the polyester industry. Catalytic conversion of glycerol to 1,3-propanediol has important application value. In this article, we reviewed the research progress of bimetallic catalysts for the hydrogenolysis of glycerol to 1,3-propanediol, especially emphasizing Pt-W catalytic systems with high catalytic efficiency and great industrial application prospects. By reviewing the interaction between W species, with different microstructures and chemical environments, and Pt metal, as well as the structure-performance relationship between Pt-W dual sites and glycerol hydrogenolysis, the influence of in-situ generated Brønsted acid active species on catalytic activity, selectivity, and stability was summarized, the source of in-situ generated Brønsted acid and catalytic mechanism was discussed, and finally, the development of bimetallic catalysts for selective hydrogenolysis of glycerol to 1,3-propanediol was prospected.

Contents

1 Introduction

2 Catalyst system for selective hydrogenation of glycerol to 1,3-Propandiol

2.1 Tungsten-based catalyst

2.2 Rhenium-based catalyst

2.3 Other catalysts

3 Mechanism of selective hydrogenolysis of glycerol to 1, 3-propanediol

3.1 Dehydration-hydrogenation mechanism

3.2 Etherification-hydrogenation mechanism

3.3 Dehydrogenation-dehydration-hydrogenation mechanism

3.4 Chelation-hydrogenation mechanism

3.5 Mechanism of direct hydrogenolysis

4 Conclusion and outlook

glycerol / chemoselective hydrogenolysis / 1,3-propanediol / bimetallic catalyst / catalytic mechanism

| [1] |

|

| [2] |

(樊利民, 王菊华, 裴文. 浙江化工, 2009, 40 (6): 22.)

|

| [3] |

|

| [4] |

(李烁, 李靖. 精细与专用化学品, 2022, 30(3): 12.)

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

陈长林, 宋敏洁, 秦丽珍. 南京工业大学学报(自然科学版), 2011, 33(1): 1.)

|

| [15] |

|

| [16] |

(龚磊峰, 吕元, 丁云杰, 林荣和, 李经伟, 董文达, 王涛, 陈维苗. 催化学报, 2009, 30(12): 1189.)

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

| [74] |

|

| [75] |

|

| [76] |

|

| [77] |

|

| [78] |

|

| [79] |

|

| [80] |

|

| [81] |

|

| [82] |

|

| [83] |

|

| [84] |

|

/

| 〈 |

|

〉 |