PDF(18082 KB)

PDF(18082 KB)

PDF(18082 KB)

PDF(18082 KB)

PDF(18082 KB)

PDF(18082 KB)

氧化物气凝胶高温红外改性研究

Research Advances on High-Temperature Infrared Modification of Oxide Aerogels

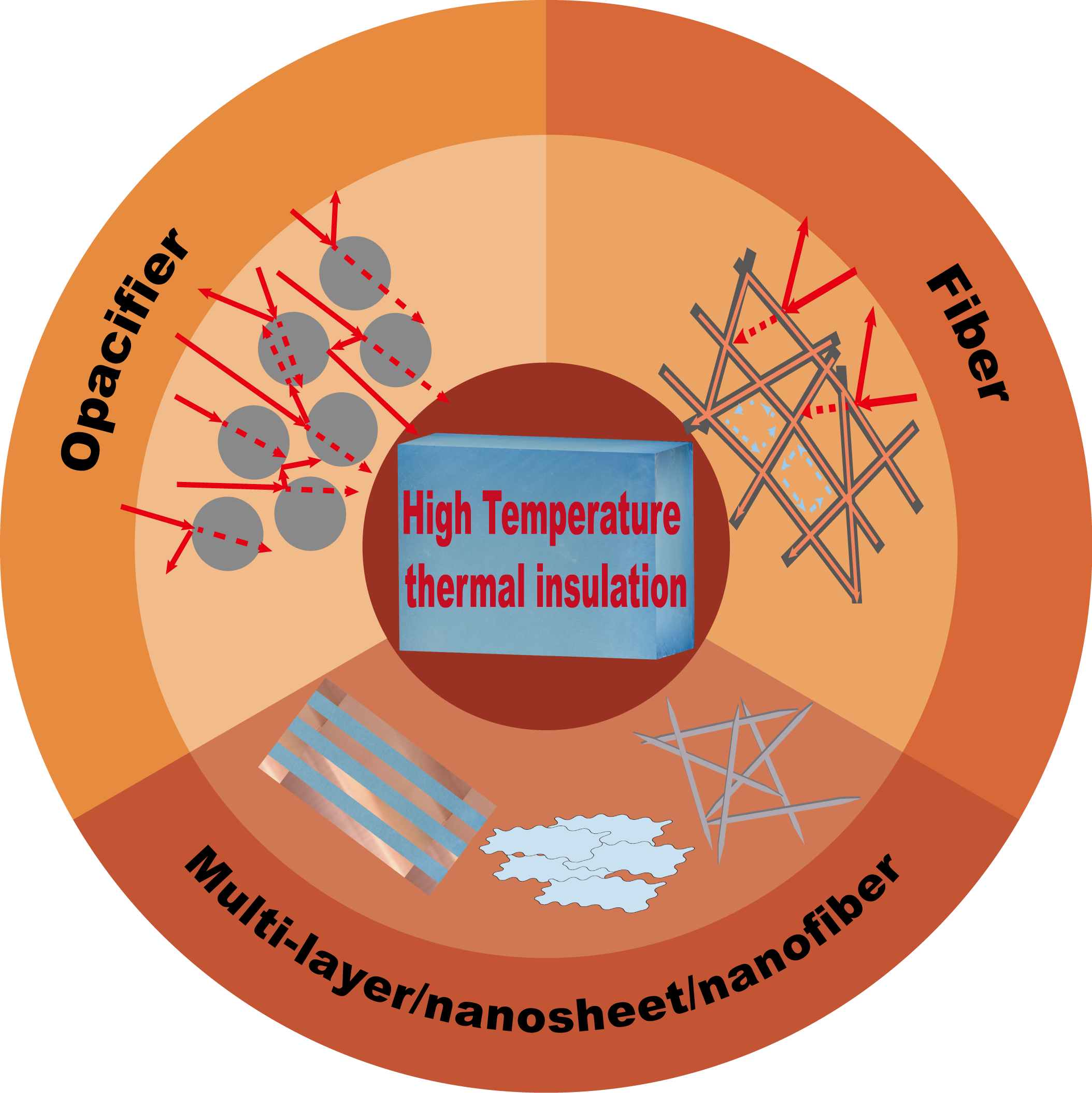

氧化物气凝胶是一类具有超低热导率的新型纳米多孔材料,在航空航天等高温隔热领域具有广阔的应用前景。然而目前常见的氧化硅、氧化铝等氧化物气凝胶受材料/结构单元固有性质的限制,其通常具有红外透明性,而高温下辐射传热占据主导地位,大量红外辐射会透过气凝胶,热导率急剧攀升,导致其高温隔热性能较差,因此需要对其进行高温红外改性,从而满足更高的隔热性能需求。本文综述了近年来添加遮光剂、纤维及调整气凝胶的结构/形貌在提高氧化物气凝胶高温隔热性能方面的研究进展,并对未来研究方向进行展望。

Oxide aerogel is a novel nano-porous material with ultra-low thermal conductivity. In particular, it can be used in spaceflight applications and other thermal management fields. Currently, with high infrared transmittance, most of the common pure oxide aerogels, such as silica and alumina, have no advantages in high-temperature insulation because of their intrinsic property. However, electromagnetic radiation in the near-infrared region is the main mode of heat conduction at high temperatures, accordingly, a large amount of electromagnetic radiation will pass through aerogel and lead to the rapid increase of thermal conductivity. Therefore, to meet the requirement of thermal insulation at higher temperature, it is necessary to reduce the radiative heat transfer. Based on the research status, this paper reviewed the main progress of improving high temperature insulation of oxide aerogel by adding opacifier, fiber and adjusting the structure and morphology. Moreover, the future research direction has prospected.

Contents

1 Introduction

2 Application of opacifiers in infrared modification of aerogels

2.1 TiO2 opacifier

2.2 SiC opacifier

2.3 Carbon materials opacifier

2.4 Other opacifier

3 Application of fiber in infrared modification of aerogels

3.1 Glass fiber

3.2 ZrO2 fiber

3.3 Mullite fiber

3.4 Modified fiber

4 Application of structure/morphology change in infrared modification of aerogels

4.1 Multiple-layer aerogel insulation materials

4.2 Lamellar aerogels

4.3 Nanofiber aerogels

5 Conclusion and outlook

氧化物气凝胶 / 红外改性 / 复合材料 / 高温隔热 / 遮光剂 / 纤维

oxide aerogel / infrared modification / composite material / high temperature insulation / opacifier / fiber

| [1] |

|

| [2] |

|

| [3] |

陈龙武, 甘礼华. 化学通报, 1997,(8): 21.)

|

| [4] |

(柳凤琦, 姜勇刚, 彭飞, 冯军宗, 李良军, 冯坚. 化学进展, 2022, 34(6): 1384.)

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

(朱召贤, 王飞, 姚鸿俊, 董金鑫, 龙东辉. 无机材料学报, 2018, 33(9): 969.)

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

(雷营生, 徐红艳, 董德平, 谢荣建. 低温与超导, 2018, 46(11): 15.)

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

(孙登科. 长安大学硕士论文, 2012.)

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

(欧阳德刚, 胡铁山, 罗安智, 赵修建. 钢铁研究, 2002, 30(1): 40.)

|

| [33] |

(张虎, 马奕新, 王娴, 冀文涛, 李跃明, 陶文铨. 工程热物理学报, 2018, 39(5): 1039.)

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

赵越, 唐桂华, 陶文铨. 工程热物理学报, 2015, 36(3): 591.)

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

秦艳青, 姜勇刚, 冯坚, 冯军宗, 岳晨午. 材料导报, 2015(11): 129.

|

| [44] |

(甘信柱. 山东大学博士论文, 2018.)

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

(冯坚, 高庆福, 冯军宗, 姜勇刚. 国防科技大学学报, 2010, 32(1): 40.)

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

(王苗, 冯军宗, 姜勇刚, 张忠明, 冯坚. 材料导报, 2016(A2): 461.)

|

| [64] |

|

| [65] |

|

| [66] |

(李健, 张凡, 张丽娟, 李文静, 赵英民. 北京理工大学学报, 2019, 39(10): 1051.)

|

| [67] |

(朱振. 哈尔滨工业大学硕士论文, 2021.)

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

/

| 〈 |

|

〉 |