PDF(86508 KB)

PDF(86508 KB)

PDF(86508 KB)

PDF(86508 KB)

PDF(86508 KB)

PDF(86508 KB)

聚合物多孔表界面材料的构筑及给药应用*

Polymeric Porous Surface Materials: Construction and Drug Delivery Applications

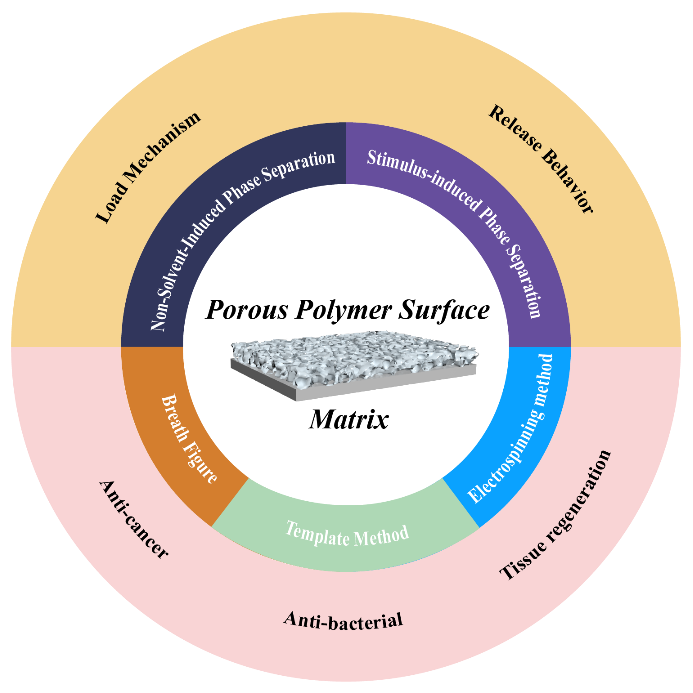

Medicine-device combined medical biomaterials provide a broad prospect for the development of traditional medical devices through the organic combination of drugs and devices. With the increasing clinical demand, the development of new surface and interface engineering technology and drug controlled release mechanism has become a hot research topic. In recent years, the porous surface and interface technology of polymer materials has realized the rapid combination of functional molecules and devices through capillary adsorption, which has the characteristics of flexible loading, controllable dosage and adjustable release, and provides new potential for promoting the precision and personalization of the combination of medical biomaterials and devices. In this review, we first summarize the preparation of porous surface and interface of polymer materials, including breathing diagram method, template method, surface non-solvent-induced phase separation method, stimulus-induced phase separation method and electrospinning method, and then elaborate the mechanism and release behavior of functional molecule delivery based on porous surface and interface of polymer materials.Then, the research progress of polymer porous surface and interface in the fields of targeted anticancer, cardiovascular implant materials, bone repair materials and so on is summarized.Finally, the challenges faced by the research of polymer porous surface and interface are summarized, and the development direction is prospected.

combination products present significant opportunities for advancing traditional medical devices by versatile integration of therapeutic drugs and devices.as clinical needs evolve,there remains growing interest in developing new surface and interface engineering technologies for modulating drug delivery behavior.Recently,polymeric porous surface interface technology has emerged As a robust strategy for the flexible amalgamation of functional molecules with medical devices via capillary adsorption.in comparison to the conventional coating method,This technology shows distinctive features like flexible loading,facile dosage control,and tunable release,therefore providing a novel insight for personalized medicine.This review begins by outlining the methods for preparing porous surfaces of polymer materials,including the breath figure,template method,surface non-solvent-induced phase separation,stimulus-induced phase separation method,and electrospinning method.Then,the mechanism for the capillary-based loading process and hindered release behavior of functional species,which play a central role in the development of spongy surface-based Combination devices,is discussed.This review also provides an overview of the latest research on the porous surface interfaces of polymer materials in applications like targeted anti-cancer,cardiovascular implants,and bone repair,summarizes the present challenges in research on the porous surfaces of polymer materials,and highlights insights into potential future directions。

1 Introduction

2 Construction strategy of porous surface on polymer materials

2.1 Breath figure

2.2 Template method

2.3 Surface non solvent induced phase separation

2.4 Stimulus-induced phase separation

2.5 Electrospinning method

3 Functional molecule delivery based on porous polymer surface

3.1 The driving force of loading and release of functional molecules

3.2 Study on the release behavior of functional molecules

4 Application of polymer porous surface in drug delivery

4.1 Targeted anti-cancer

4.2 Cardiovascular diseases

4.3 Orthopedics diseases

5 Conclusion

combination products / porous materials / surface engineering / drug delivery

| [1] |

(张兴栋, 大卫·威廉姆斯. 21世纪生物材料定义. 科学出版社, 2021.).

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

About Combination Products, (2019-06-18). [2023-01-30]. https://www.fda.gov/combination-products/about-combination-products

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

Tan, Rodrigue. Polymers, 2019, 11(8): 1310.

|

| [16] |

|

| [17] |

|

| [18] |

(徐又一, 徐志康. 高分子膜材料. 北京: 化学工业出版社, 2005.).

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

(王涛, 朴香兰, 朱慎林. 高等传递过程原理. 北京: 化学工业出版社, 2005.).

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

| [74] |

|

| [75] |

|

| [76] |

|

| [77] |

|

| [78] |

|

| [79] |

|

| [80] |

|

| [81] |

|

| [82] |

|

| [83] |

|

| [84] |

|

| [85] |

|

| [86] |

|

| [87] |

|

| [88] |

|

| [89] |

|

| [90] |

|

| [91] |

|

| [92] |

|

| [93] |

|

| [94] |

|

| [95] |

|

| [96] |

|

| [97] |

|

| [98] |

|

| [99] |

|

| [100] |

|

| [101] |

|

| [102] |

|

| [103] |

|

| [104] |

|

| [105] |

|

| [106] |

|

| [107] |

|

| [108] |

|

| [109] |

|

| [110] |

|

| [111] |

|

| [112] |

|

| [113] |

|

| [114] |

|

| [115] |

|

| [116] |

|

| [117] |

|

| [118] |

|

| [119] |

|

| [120] |

|

| [121] |

|

| [122] |

|

| [123] |

|

/

| 〈 |

|

〉 |