PDF(3834 KB)

PDF(3834 KB)

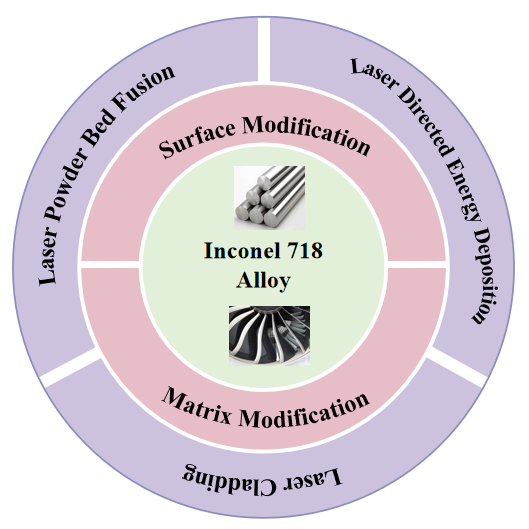

Laser Additive Manufacturing Inconel 718 Matrix Composites and Their Mechanical Performances

Zhong Qiaofang, Li Mengjie, Hu Yanqiu, Qu Chao, Zhang Haijun, Liu Jianghao

Prog Chem ›› 2025, Vol. 37 ›› Issue (9) : 1384-1396.

PDF(3834 KB)

PDF(3834 KB)

PDF(3834 KB)

PDF(3834 KB)

Laser Additive Manufacturing Inconel 718 Matrix Composites and Their Mechanical Performances

Owing to its high temperature strength, high ductility and good corrosion resistance, Inconel 718 (IN718) alloy had broad application prospects in aerospace, military and energy fields. However, the low hardness and wear resistance of IN718 alloy severely limited its application. To solve these problems, one of the feasible strategies was to modify the composition/microstructure of IN718 alloy. Laser additive manufacturing methods had the capabilities of effectively regulating the composition and microstructure of composite materials, so as to enhance their mechanical performances. Herein, the intrinsic properties and compositional modification strategies of IN718-matrix composites were first introduced, and then the advantages and limitations of laser-additive-manufactured IN718-matrix composites were summarized, respectively. Subsequently, the evolution laws of microstructural morphologies and mechanical performances of IN718-matrix composites prepared by laser additive manufacturing methods were summarized. Finally, the key scientific problems in modifying the preparation method, regulating microstructure and optimizing mechanical performances of IN718-matrix composites were respectively clarified, and the future developments were prospected.

1 Introduction

2 Modification of IN718 alloy

2.1 Surface modification

2.2 Matrix modification

3 Laser additive manufacturing methods for IN718 matrix composites

3.1 Laser Powder Bed Fusion

3.2 Laser Directed Energy Deposition

3.3 Laser Cladding

4 Microstructure and mechanical performances of laser additive manufacturing IN718 matrix composites

4.1 Surface modification

4.2 Matrix modification

5 Conclusion and outlook

IN718-matrix composites / laser additive manufacturing / surface modification / matrix modification / microstructure / mechanical performances

| [1] |

( 黄金鑫, 孙中刚, 常辉, 唱丽丽, 邢飞, 周廉. 稀有金属材料与工程, 2020, 49(08): 2813 ).

|

| [2] |

庄景云, 杜金辉, 邓群, 曲敬龙, 吕旭东. 变形高温合金GH4169. 北京: 冶金工业出版社, 2006).

|

| [3] |

|

| [4] |

De Bartolomeis A,

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

孟贵如. 东北大学硕士论文, 2021 ).

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

( 石晨晓, 刘元富, 李勇, 孙广宝, 张政, 冯志成. 稀有金属材料与工程, 2019, 48(5): 1497).

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

( 贾晓慧, 胡亚宝, 宋欣灵, 方艳, 雷剑波. 表面技术, 2022, 51(12): 329).

|

| [22] |

|

| [23] |

|

| [24] |

( 牛薪, 晁明举, 周笑薇, 王东升, 袁斌. 中国激光, 2005, 32(11): 1583 ).

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

( 张丹丹, 郭长虹, 勾兴军, 战再吉. 燕山大学学报, 2014, 38(6): 484 ).

|

| [36] |

|

| [37] |

|

| [38] |

( 顾冬冬, 张红梅, 陈洪宇, 张晗, 席丽霞. 中国激光, 2020, 47(5): 0500002).

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

贾清波. 南京航空航天大学硕士论文, 2015).

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

( 张昊, 戴冬华, 石新宇, 历彦泽, 袁鲁豪, 黄广靖, 顾冬冬. 中国激光, 2022, 49(14): 1402208).

|

| [52] |

|

| [53] |

( 张天刚, 孙荣禄. 中国激光, 2018, 45(1): 102002).

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

( 陈瑶, 王华明. 稀有金属材料与工程, 2003, 32(10): 840).

|

| [58] |

|

| [59] |

|

| [60] |

王辰阳. 沈阳工业大学硕士论文, 2021).

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

( 石齐民, 顾冬冬, 顾荣海, 陈文华, 戴冬华, 陈洪宇. 稀有金属材料与工程, 2017, 46(6): 1543 ).

|

| [66] |

( 李惠, 张建勋, 卢秉恒. 中国激光, 2023, 50(8): 0802307).

|

| [67] |

|

| [68] |

( 鲁耀钟, 雷卫宁, 任维彬, 陈世鑫. 表面技术, 2020, 49(9): 233).

|

| [69] |

( 吴军, 金杰, 朱冬冬, 徐军飞, 张玉良. 表面技术, 2021, 50(9): 225 ).

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

| [74] |

|

| [75] |

|

| [76] |

|

| [77] |

|

| [78] |

|

| [79] |

|

| [80] |

|

| [81] |

|

| [82] |

|

| [83] |

|

| [84] |

|

| [85] |

|

| [86] |

|

| [87] |

|

| [88] |

|

| [89] |

|

/

| 〈 |

|

〉 |