PDF(13765 KB)

PDF(13765 KB)

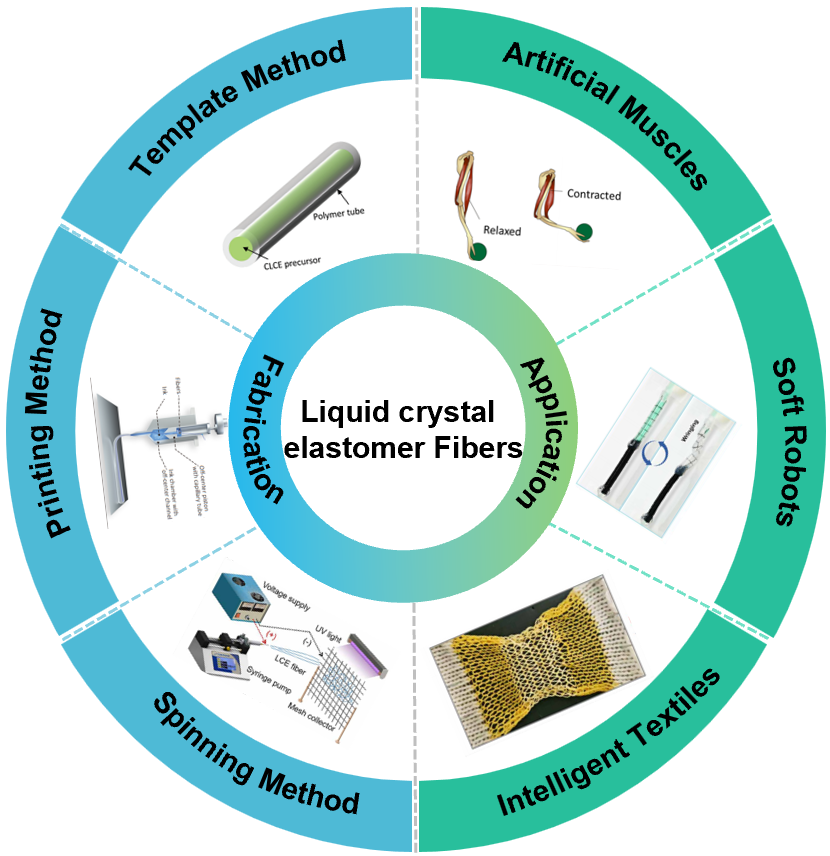

Fabrication and Application of Liquid Crystal Elastomer Fibers

Shan Yuanhang, Hu Jun, Wang Meng

Prog Chem ›› 2025, Vol. 37 ›› Issue (9) : 1342-1351.

PDF(13765 KB)

PDF(13765 KB)

PDF(13765 KB)

PDF(13765 KB)

Fabrication and Application of Liquid Crystal Elastomer Fibers

Liquid crystal elastomers (LCEs) are crosslinked polymer networks that combine the anisotropy of liquid crystals with the entropic elasticity of elastomers. They exhibit reversible large deformations under external stimuli, making them a focal point in smart materials research. Among various forms, LCE fibers, characterized by their high aspect ratio and large specific surface area, demonstrate enhanced sensitivity, greater deformation capacity, and excellent reversibility, weavability, and programmability, significantly broadening their application potential. In recent years, advancements in manufacturing technologies have expanded the fabrication methods of LCE fibers from traditional pulling and templating techniques to advanced spinning technologies such as melt spinning, electrospinning, wet spinning, and emerging 3D/4D printing techniques. These innovations have not only provided more possibilities for structural design and performance optimization of LCE fibers but also promoted their widespread use in high-performance material applications. This article systematically reviews the molecular structure and diverse fabrication methods of LCE fibers, discusses their applications in artificial muscles, soft robotics, smart clothing, and wearable devices, and provides an outlook on the future development of LCE fibers.

1 Introduction

2 Molecular structures of liquid crystal elastomer fiber

3 Fabrication technology of liquid crystal elastomer fiber

3.1 Pultrusion method

3.2 Template method

3.3 Printing method

3.4 Spinning method

3.5 Microfluidic method

4 Application of liquid crystal elastomer fiber

4.1 Artificial muscles

4.2 Soft robots

4.3 Intelligent textiles

5 Conclusion and outlook

liquid crystal elastomer / fiber / soft robot / artificial muscle

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

| [74] |

|

| [75] |

|

/

| 〈 |

|

〉 |