PDF(8433 KB)

PDF(8433 KB)

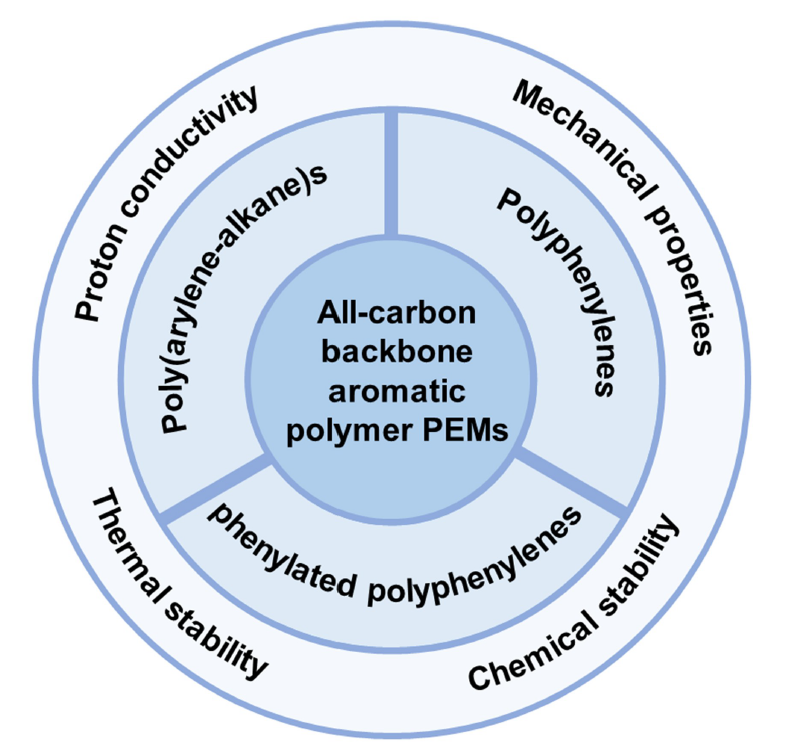

Proton Exchange Membranes Based on All-Carbon Backbone Aromatic Polymers

Li Tingting, Li Haibin, Liu Binghui, Zhao Chengji, Li Haolong

Prog Chem ›› 2023, Vol. 35 ›› Issue (11) : 1559-1578.

PDF(8433 KB)

PDF(8433 KB)

PDF(8433 KB)

PDF(8433 KB)

Proton Exchange Membranes Based on All-Carbon Backbone Aromatic Polymers

Proton exchange membranes are widely used in energy storage and conversion technologies such as fuel cells, redox flow batteries, and water electrolysis, which are key materials urgently needed under the “dual carbon” goal. Perfluorosulfonic acid membranes show high proton conductivity and mechanical properties, which are currently the most widely used proton exchange membranes materials. However, these membranes suffer from the following disadvantages, such as greatly decreased proton conductivity at low humidity conditions, low glass transition temperature, and complex synthesis process. In the past decades, efforts have been devoted to the development of various alternative materials, such as polyether ether ketone, polyphenylene oxide, polysulfone and polyimide. However, the main chains of these polymers usually contain heteroatoms. Upon working in a complex practical condition for a long time, the heteroatom position is prone to break, which reduces the chemical stability of these materials. In contrast, the all-carbon backbone aromatic polymers have excellent chemical stability, thermal stability, and mechanical properties, and are a class of potential alternative materials that have attracted extensive attention in recent years. In this review paper, we summarize the recent research progress of all-carbon backbone aromatic polymers, focusing on the synthesis strategies, structure-performance relationships, as well as the applications of these polymers in proton exchange membranes.

1 Introduction

2 Proton exchange membranes based on polyphenylenes

2.1 Synthesis and general properties

2.2 Straight-chain sulfonated polyphenylene proton exchange membranes

2.3 Curve-chain sulfonated polyphenylene proton exchange membranes

3 Proton exchange membranes based on phenylated polyphenylenes

3.1 Synthesis and general properties

3.2 Sulfonated phenylated polyphenylene proton exchange membranes

3.3 Phosphoric acid doped phenylated polyphenylene proton exchange membranes

4 Proton exchange membranes based on poly(arylene-alkane)s

4.1 Synthesis and general properties

4.2 Sulfonated poly(arylene-alkane)proton exchange membranes

4.3 Phosphorylated poly(arylene-alkane)proton exchange membranes

4.4 Phosphoric acid doped poly(arylene-alkane)proton exchange membranes

5 Conclusion and outlook

proton exchange membranes / all-carbon backbone aromatic polymers / proton conductivity / chemical stability / structure-performance relationships

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

| [74] |

|

| [75] |

|

| [76] |

|

| [77] |

|

| [78] |

|

| [79] |

|

| [80] |

|

| [81] |

|

| [82] |

|

| [83] |

|

| [84] |

|

| [85] |

|

| [86] |

|

| [87] |

|

| [88] |

|

| [89] |

|

| [90] |

|

| [91] |

|

| [92] |

|

| [93] |

|

| [94] |

|

| [95] |

|

| [96] |

|

| [97] |

|

| [98] |

|

| [99] |

|

| [100] |

|

| [101] |

|

| [102] |

|

| [103] |

|

| [104] |

|

| [105] |

|

| [106] |

|

| [107] |

|

| [108] |

|

| [109] |

|

| [110] |

|

| [111] |

|

| [112] |

|

| [113] |

|

| [114] |

|

| [115] |

|

| [116] |

|

| [117] |

|

/

| 〈 |

|

〉 |