PDF(85792 KB)

PDF(85792 KB)

Research Progress of Ni-Rich Cathode Materials

Tianyu Wang, Li Wang, Wei Sun, Meirong Wu, Yue Yang

Prog Chem ›› 2024, Vol. 36 ›› Issue (7) : 1026-1045.

PDF(85792 KB)

PDF(85792 KB)

PDF(85792 KB)

PDF(85792 KB)

Research Progress of Ni-Rich Cathode Materials

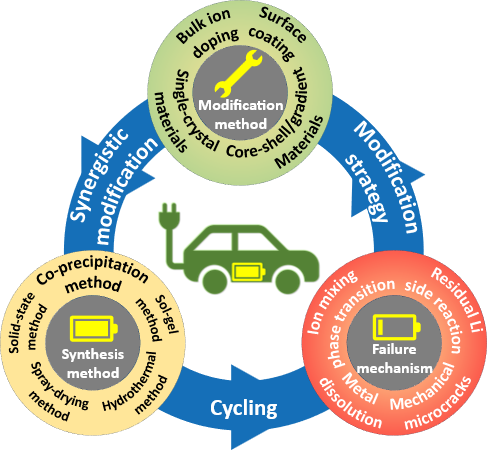

Benefiting from high energy density and low cost,Ni-rich LiNixCoyMn/Al1-x-yO2materials have received great attention as promising cathode candidates for next-generation high-energy lithium-ion batteries(LIBs)that are widely used in electric vehicles(EVs).However,with an increased Ni content,Ni-rich cathode materials suffer from severe structural,chemical,and mechanical instabilities,seriously restricting their industrially safe application in power LIBs of EVs.In this review,primarily,the synthesis methods of Ni-rich cathode materials are summarized in detail,which include solid-state method,sol-gel method,hydrothermal method,spray-drying method,and co-precipitation method.Subsequently,the key failure mechanisms,including ion mixing and irreversible phase transition,residual Li species and interface side reactions,mechanical microcracks,and transition metal dissolutions,are thoroughly analyzed throughout the preparation,storage,and service of Ni-rich cathode materials,thereby clarifying various performance decay behaviors of materials.The modification strategies that cover ion doping,surface coating,core-shell/gradient materials,and single-crystal materials are systematically discussed for Ni-rich cathode materials,aiming at presenting conspicuous research progress and current shortcomings for the stabilization of Ni-rich cathode materials.Finally,this review presents a perspective toward future development and optimization for Ni-rich cathode materials,aiming at delivering a theoretical guidance for propelling its industrial safe application in high-energy LIBs 。

1 Introduction

2 Synthetic method

2.1 Solid-state method

2.2 Sol-gel method

2.3 Hydrothermal method

2.4 Spray-drying method

2.5 Coprecipitation method

3 Failure mechanism

3.1 Ion mixing and irreversible phase transition

3.2 Surface residual Li species and interface side reaction

3.3 Microcracks induced by internal stress

3.4 Dissolution of transition metals

4 Modification method

4.1 Ion doping

4.2 Surface coating

4.3 Core-shell/gradient material design

4.4 Single-crystal material design

5 Conclusion and outlook

Ni-rich cathode materials / synthesis methods / failure mechanism / modification methods / synergistic modification

| [1] |

|

| [2] |

(杨续来, 袁帅帅, 杨文静, 刘闯, 杨世春. 机械工程学报, 2023, 59: 239.).

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

| [74] |

|

| [75] |

|

| [76] |

|

| [77] |

|

| [78] |

|

| [79] |

|

| [80] |

|

| [81] |

|

| [82] |

|

| [83] |

|

| [84] |

|

| [85] |

|

| [86] |

|

| [87] |

|

| [88] |

|

| [89] |

|

| [90] |

|

| [91] |

|

| [92] |

|

| [93] |

|

| [94] |

|

| [95] |

|

| [96] |

|

| [97] |

|

| [98] |

|

| [99] |

|

| [100] |

|

| [101] |

|

| [102] |

|

| [103] |

|

| [104] |

|

| [105] |

|

| [106] |

|

| [107] |

|

| [108] |

|

| [109] |

|

| [110] |

|

| [111] |

|

| [112] |

|

| [113] |

|

| [114] |

|

| [115] |

|

| [116] |

|

| [117] |

|

| [118] |

|

| [119] |

|

| [120] |

|

| [121] |

|

| [122] |

|

| [123] |

|

| [124] |

|

| [125] |

|

| [126] |

|

| [127] |

|

| [128] |

|

| [129] |

|

| [130] |

|

| [131] |

|

| [132] |

|

| [133] |

|

| [134] |

|

| [135] |

|

| [136] |

|

| [137] |

|

| [138] |

|

| [139] |

|

| [140] |

|

| [141] |

|

| [142] |

|

| [143] |

|

| [144] |

|

| [145] |

|

| [146] |

|

| [147] |

|

| [148] |

|

| [149] |

|

| [150] |

|

/

| 〈 |

|

〉 |