PDF(16668 KB)

PDF(16668 KB)

Research Progress of Nanofiber Composite Hydrogels

Yvqing Ma, Zheng Li, Guobao Zheng, Songnan Zhang, Jixian Gong, Changsheng Qiao

Prog Chem ›› 2024, Vol. 36 ›› Issue (10) : 1594-1606.

PDF(16668 KB)

PDF(16668 KB)

PDF(16668 KB)

PDF(16668 KB)

Research Progress of Nanofiber Composite Hydrogels

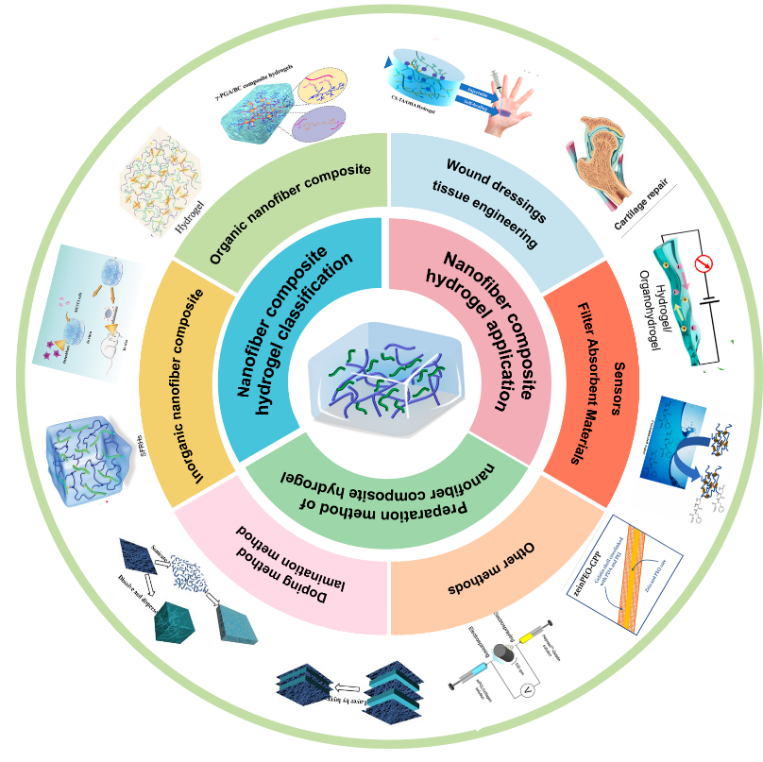

Hydrogels have become one of the most widely researched materials across disciplines due to their excellent softness, wettability, responsiveness and biocompatibility. However, the mechanical properties of hydrogels are poor and cannot meet the use of some special materials. Nanofibers have been used to prepare nanofiber composite hydrogels with nano-size, porous structure and tunable mechanical properties due to their high aspect ratio, uniform fiber morphology and easy functionalization. Nanofiber composite hydrogels have suitable mechanical properties, ductility, adhesion, and the ability to mimic the microstructure of the extracellular matrix (ECM) and the microenvironment of the cell, which makes them widely used in many fields. This paper summarizes the classification of nanofiber composite hydrogels, their preparation methods and their development and application in the fields of multifunctional wound dressings, tissue engineering, sensors, and filter absorption materials future development.

Contents

1 Introduction

2 Nanofiber composite hydrogel classification

2.1 Organic nanofiber composite hydrogel l

2.2 Inorganic nanofiber composite hydrogel

2.3 Organic-inorganic hybrid nanofiber composite hydrogels

3 Preparation method of nanofiber composite hydrogel

3.1 Doping method

3.2 lamination method

3.3 Other methods

4 Nanofiber composite hydrogel application

4.1 Multifunctional wound dressing

4.2 Tissue engineering

4.3 Conductive sensors

4.4 Absorbent filter material for dye and metal ion removal

5 Conclusions and outlook

nanofiber / hydrogel / composite material / mechanical property

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

(吕东, 杨琥, 郭学锋, 程镕时. 化学进展, 2010, 22(05):948.)

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

(李泓, 张静, 陈可, 罗程严, 徐春波, 梁宸, 李波, 肖文谦, 廖晓玲. 复合材料学报, 2020, 37(10):2572.)

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

(于靖, 孙莺, 王鹏, 陈鹏, 张永刚. 高分子通报, 2019, (5):1.)

|

| [51] |

(马颖, 王建全, 李向梅, 邵自强. 高分子材料科学与工程, 2021, 37(10):137.)

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

(殷星, 王璇, 马洪洋. 中国材料进展, 2019, 38(5):457-463.)

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

| [74] |

|

| [75] |

|

| [76] |

|

| [77] |

|

| [78] |

|

| [79] |

|

| [80] |

|

| [81] |

|

| [82] |

|

| [83] |

|

| [84] |

|

| [85] |

|

| [86] |

|

| [87] |

|

| [88] |

|

| [89] |

|

| [90] |

|

| [91] |

|

| [92] |

|

| [93] |

|

| [94] |

|

| [95] |

|

| [96] |

|

| [97] |

|

| [98] |

|

| [99] |

|

| [100] |

|

| [101] |

|

| [102] |

|

| [103] |

|

| [104] |

|

| [105] |

|

| [106] |

|

| [107] |

|

| [108] |

|

| [109] |

|

| [110] |

|

/

| 〈 |

|

〉 |