Synthesis of Two-Dimensional Layered Zeolites and Their Catalysis, Adsorption and Separation Applications

Received date: 2023-07-18

Revised date: 2023-11-21

Online published: 2024-02-26

Supported by

National Key R&D Program of China(2018YFA0209402)

National Natural Science Foundation of China(22072028)

National Natural Science Foundation of China(22088101)

Shanghai Natural Science Foundation(22ZR1407200)

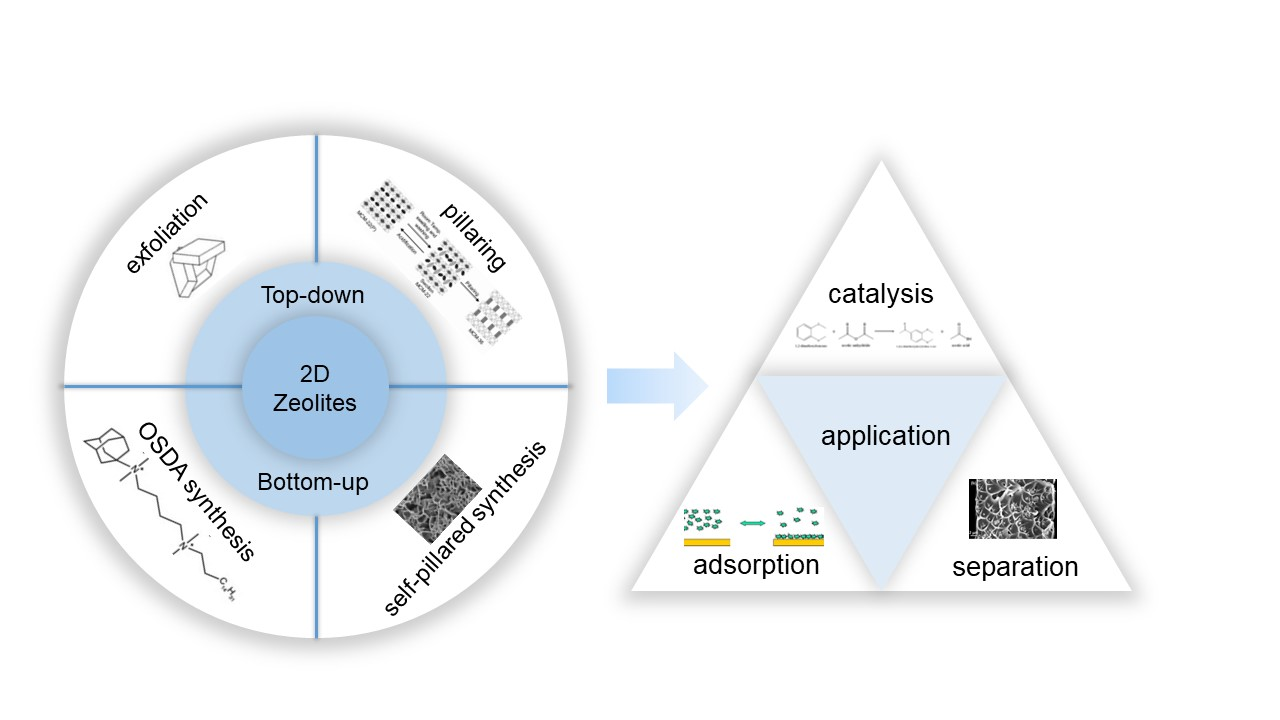

Compared with three-dimensional zeolites, two-dimensional layered zeolites have greater advantages in many fields, with larger surface area, shorter diffusion distance and more ductile structure. In recent years, the research on two-dimensional layered zeolites has become a new hotspot. Based on previous research and summary, this article summarizes the synthesis methods of two-dimensional zeolites in the past five years from two types of synthesis perspectives (bottom-up and top-down methods), with a focus on reviewing the progress of different synthesis methods for the same topology of zeolite. In addition, this article briefly describes the applications of two-dimensional zeolites in the fields of catalysis, adsorption, and separation and looks forward to the broad application prospects of two-dimensional zeolites so as to provide theoretical guidance and reference basis for the synthesis and application of two-dimensional zeolites.

1 Introduction

2 Synthesis of two-dimensional layered zeolites

2.1 Bottom-up synthesis method

2.2 Top-down synthesis method

3 Application of two-dimensional layered zeolite

3.1 Catalysis

3.2 Adsorption

3.3 Separation membrane

4 Conclusion and outlook

Key words: 2D zeolite; synthesis; acid catalysis; adsorption; separation membrane

Shiyu Hu , Yueer Yan , Yahong Zhang , Zhendong Wang , Yi Tang . Synthesis of Two-Dimensional Layered Zeolites and Their Catalysis, Adsorption and Separation Applications[J]. Progress in Chemistry, 2024 , 36(3) : 319 -334 . DOI: 10.7536/PC230716

图4 用C22-6-6/TPAOH摩尔比为10/0(a)、10/1(b)、10/2(c)、10/3(d)、10/5(e)、10/8(f)、10/12(g)和10/20(h)制备的MFI沸石的扫描电子显微镜(SEM)图像[44]。Si/Al比为~40(i)的商用MFI沸石作为对照Fig. 4 SEM images of MFI zeolites obtained with C22-6-6/TPAOH molar ratio of (a) 10/0, (b) 10/1, (c) 10/2, (d) 10/3, (e) 10/5, (f) 10/8, (g) 10/12, and (h) 10/20, respectively, in the dual template synthesis. (i) Commercial MFI with Si/Al ratio of ∼40 was used for comparison[44]. Copyright © 2014, American Chemical Society |

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

| [74] |

|

| [75] |

|

| [76] |

|

| [77] |

|

| [78] |

|

| [79] |

|

| [80] |

|

| [81] |

|

| [82] |

|

| [83] |

|

| [84] |

|

| [85] |

|

| [86] |

|

| [87] |

|

| [88] |

|

| [89] |

|

| [90] |

|

| [91] |

|

| [92] |

|

| [93] |

|

| [94] |

|

| [95] |

|

| [96] |

|

| [97] |

|

| [98] |

|

| [99] |

|

| [100] |

|

| [101] |

|

| [102] |

|

| [103] |

|

| [104] |

|

| [105] |

|

/

| 〈 |

|

〉 |