Hydrogel-Based Textile Composites

Received date: 2023-10-07

Revised date: 2024-02-27

Online published: 2024-07-01

Supported by

Ningxia Key Research and Development Project(2022BEG02006)

Tianjin Key Research and Development Project(20YFZCSN00130)

Central Government of Heilongjiang Province Guides Funds(ZY23CG35)

Ningxia Autonomous Region Flexible Introduction of Science and Technology Innovation Team(2021RXTDLX08)

Hydrogel materials are widely used due to their excellent hydrophilicity,biocompatibility,adjustable biomimetic properties,etc.However,their inherent non-uniform microstructure and low-density molecular chains make their mechanical properties poor,which limits their practical applications.the preparation of hydrogel materials with high mechanical strength yet toughness has been a challenge for research in This field.As composites are constantly developing in the direction of functionalization and intelligence,the introduction of polymer hydrogels into the textile field for the preparation of gel-based textile composites not only improves the defects of gel materials,but also gives textiles excellent properties and broadens their potential application prospects.this paper reviews the research progress of hydrogel textile composites,focusing on the design strategy of hydrogel-based textile composites and their enhanced mechanical and antimicrobial properties,discusses the application progress of the composites in the fields of oil-water separation,medical dressings,wearable electronic devices,and flame-retardant protection,and the future research direction is also prospected.

1 Introduction

2 Methods to prepare hydrogel textile composites

2.1 Sol-gelatinization

2.2 Graft modification treatment

2.3 Lamination

2.4 Hydrogel fiber weaving method

3 Application of hydrogel textile composites

3.1 Oil-water separation

3.2 Medical Dressings

3.3 Wearable electronic devices

3.4 Flame retardant protective products

3.5 Others

4 Conclusion and outlook

Key words: hydrogel textiles; composite material; surface modification

Wanru Guo , Zheng Li , Bing Liu , Jixian Gong , Songnan Zhang , Guobao Zheng . Hydrogel-Based Textile Composites[J]. Progress in Chemistry, 2024 , 36(6) : 914 -927 . DOI: 10.7536/PC231002

表1 Preparation of Hydrogel Textile CompositeTable 1 Preparation of hydrogel textile composites |

| Method | Content | Hydrogel material | Other materials | Ref | |

|---|---|---|---|---|---|

| Sol-gel method | Dip method | The sol-gel immersion technique was used to enhance the nonwoven cotton by immersion in the cellulose solution to form a cellulose hydrogel/nonwoven cotton composite material. | Cellulose hydrogel | Cotton nonwoven | 20 |

| Wool nonwovens were immersed in an aqueous sodium alginate solution and then passed through a calcium chloride solution to form hydrogel composites. | Sodium alginate | Wool nonwoven | 21 | ||

| Soaking strategy was employed and nonwoven fabrics were introduced to preparation of the hydrogel composites. | Gelatin, chitosan | Polylactic acid nonwoven | 22 | ||

| The polyvinyl alcohol and sodium alginate mixed solution were evenly injected into the three-dimensional cotton fiber network, and the PVA-SA hydrogel was enhanced by freeze-thaw cycle and high temperature annealing. | Poly (vinyl alcohol), Na-alginate | Cotton | 23 | ||

| Coating | The zwitterionic hydrogel-coated cotton fabrics were prepared by stepwise coating and post-gel route. | PSBMA/PVA/Borax | Cotton fabric | 25 | |

| Hydroxyethyl cellulose, poly(acrylic acid) | Cotton fabric | 26 | |||

| The dihydrolipoic acid-modified sulfobetaine-derived starch hydrogel coating was covalently immobilized on the PDA/PET surface via Michael addition reaction. | Sulfobetaine-derived starch | The PET surface modified with PDA | 27 | ||

| Graft modification | Chemical grafting | The PET fabric surface was graft polymerized by activated acrylic acid and then soybean isolate protein hydrogel was coated on the fabric surface. | Soy protein isolate | PET fabric | 29 |

| Nanohydrogels were synthesized by one-step method, and SCGN nanohydrogels were grafted to the surface of cotton fabric by chemical grafting. | NCO-SCG Nanohydrogel | Cotton fabric | 30 | ||

| Light grafting | Pretreatment with argon plasma, light-induced surface graft polymerization, and PNIPAAm hydrogels were grafted onto polypropylene non-woven fabrics and PET surfaces. | Poly(N-isopropylacrylamide) | Polypropylene non-woven, PET | 33 | |

| Bifunctional groups were introduced into the PET surface by the aminolysis reaction of allylamines. The grafted polymer networks were obtained after UV-induced radical photopolymerization by varying acrylate monomer types. | N-isopropylacrylamide | PET fabric | 34 | ||

| The hydrogel with different structures were obtained by introducing resorcinol acrylic diglycidyl ester into PET surface through dip rolling and baking methods, and initiating free radical polymerization on PET fabric surface under UV light. | Polyacrylamide, polyacrylic acid, poly (N-isopropylacrylamide) | PET fabric | 35 | ||

| Plasma grafting | Three low-temperature plasma gases (oxygen, nitrogen, and argon) were used to activate the surface of cotton fibers to prepare PN/CS hydrogel textiles. | Poly(N-isopropylacrylamide), Chitosan | Cotton fabric | 36 | |

| The surface of PET fabric was modified by plasma treatment, and nano gel was synthesized by free radical polymerization to prepare composite materials. | N-isopropylacrylamide | PET fabric | 37 | ||

| The double network composite hydrogel was enhanced by plasma graft PLA fused-blown nonwoven fabric and polyethylene glycol dimaleate. | Polyethylene glycol dimaleate | Polylactic acid non-woven | 39 | ||

| Laminating | A method was reported to combine hydrogels with elastomers via a glass fiber fabric interphase. | Polyampholyte, Polydimethylsiloxane | Glass fiber fabric | 40 | |

| This study constructed a multiscale gel-fabric soft composite synergistically toughened by Pluronic/PMEA hydrogel, hydroxyapatite nanoparticles (HAP NPs) and aramid fabric. | Pluronic F127 Diacrylate, Methoxyethyl acrylate | Aramid fabric | 41 | ||

| Hydrogel fiber weaving method | Nonweaving method | This study selected ethanol-soluble PA as the spinning polymer and fabricate the green electrospun EPA fibrous membranes. The composite material was formed by uniformly coating the polyacrylate onto the EPA fibrous membranes. | Fluorinated polyacrylate | Electrostatic spun polyamide fiber membrane | 48 |

| Hydrogel composite materials based on hydroxypropyl cellulose has been produced using the nonwoven solution blown technique followed by thermal cross-linking with citric acid. | Hydroxypropyl cellulose | / (nonwoven fabrics) | 50 | ||

| The gelatin hydrogel nonwoven fabrics were prepared by the solution blow spinning method. | Gelatin | / (nonwoven fabrics) | 51 | ||

| Weaving method | 3D fabric-enhanced hydrogel composite materials composed of acrylamide and sodium alginate are expected to be used for cartilage replacement. | Acrylamide, sodium alginate | / | 52 | |

| The PVA yarn is dissolved in the fabric and transformed into cross-linked gel structure, which penetrates between yarns in the form of matrix to obtain hydrogel composites. | Polyvinyl alcohol | Cotton | 53 | ||

| regenerated cellulose fiber | 56 | ||||

| The HOGFs were designed via a wet-spinning strategy. Owing to the good knittable feature, the HOGFs can be readily woven to adjusted 2D textiles to function. | Poly(ethylene glycol) diacrylate, N-(2-hydroxyethyl) acrylamide, SA | / | 57 | ||

| The composite fibers, Ecoflex-polyacrylamide fibers (EPFs), are created through the combination of heterogeneous elastomers and strong interfacial coupling. | Acrylamide | / | 58 | ||

| A continuous dry-wet spinning method was developed to prepare hydrogel fibers. By tuning the contents of acrylamide and N-acryloylglycinamide, the hydrogel precursor exhibits thermally reversible sol-gel transition. | Acrylamide, N-acryloylglycinamide | / | 59 | ||

| The hydrogel was compounded with an elastic polyacrylamide hydrogel to produce a hydrogel core sheath fiber, and blended with a liquid metal core sheath fiber to produce a smart fabric. | Mineral hydrogel, polyacrylamide, metal fibre | / | 60 | ||

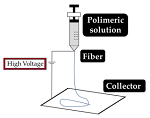

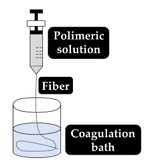

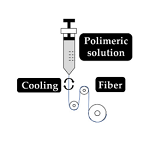

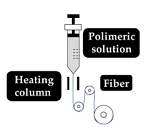

表2 Common gel fiber manufacturing technology[43]Table 2 Common gel fiber manufacturing techniques[43] |

| Setup | Concept | Ref | |

|---|---|---|---|

| Electro-spinning |  | The polymer dissolved in an appropriate solvent is injected by a needle towards a collection plate. Due to the high applied electric field, potential difference generated between the syringe and the plate, the polymer is attracted by the collecting plate, and the polymer solution is converted into nanofibers. | 44 |

| Wet-Spinning |  | The polymer is dissolved in an appropriate solvent and later injected through a fiery into a coagulation bath containing a non-solvent liquid. In the coagulation bath, continuous polymerization of the filaments occurs. After the formation of the fibers, they are extracted from the coagulation bath by means of rollers-induced capture. | 45 |

| Melt-Spinning |  | The solid polymer is heated above its melting point within the extruder and is then expelled through a die, solidifying on cooling. In a pick-up, the fibers are then recovered and mechanically stretched. | 46 |

| Dry-Spinning |  | The polymer is dissolved in a suitable solvent. The initial solution is injected through the spinneret and through a heating column that causes the solvent to evaporate. Consequently, the polymer solidifies, and dry fibers are attained. | 47 |

表3 Related Applications of Hydrogel Textile CompositesTable 3 The application of hydrogel textile composites |

| Researcher | Content | Application | Ref |

|---|---|---|---|

| Liu | The zwitterionic hydrogel-coated cotton fabrics were prepared by stepwise coating and post-gel route. | Oil-water separation | 25 |

| Liu | A novel Ag/AgCl nanoparticles hybrid cellulose-based hydrogel (AHCH) was successfully prepared, it was coated on a piece of cotton fabric through the facile sol-gel coating method. | Oil-water separation | 26 |

| You | A natural polymer-based hydrogel prepared by konjac glucomannan was coated on glass fabric. | Oil-water separation | 63 |

| Cai | The method of a super hydrophilic fabric composed of basalt fiber and KGM was reported. The composite shows stable super hydrophobic property in water. | Oil-water separation | 70 |

| Dai | A guar gum self-assembled hydrogel for oil-water separation was prepared and coated on cotton fabric by coating method. | Oil-water separation | 71 |

| Türkoğlu | A hydrogel dressing supported by regenerated cellulose non-woven fabric was developed, which has the characteristics of rapid and effective treatment of high swelling wounds. | Wound dressing | 80 |

| Benltoufa | Chitosan hydrogel has been synthetized and applied on cellulosic fabric to impart antimicrobial behavior. It is suitable for medical, surgical and transdermal treatment applications. | Wound dressing | 81 |

| Ahmad | The study fabricated cellulose hydrogel using the sol-gel technique and reinforced it with nonwoven cotton for sustainable wound dressing application. | Wound dressing | 20 |

| Wang | The sandwich-like composite hydrogel wound dressings were developed by intercalating nonwoven fabrics as the middle layer, gelatin and chitosan hydrogel loaded with Centella asiatica as the base materials. | Wound dressing | 22 |

| Xu | A touch sensing fabric system composed of non-woven cellulose fabric was proposed, | wearable electronics | 87 |

| Kang | A flexible and stretchable supercapacitor was assembled by direct interfacial gelation of reduced graphene oxide with carbon nanotubes on a stretchable fabric surface. | wearable electronics | 88 |

| Xu | A breathable paper-cut ionic e-textile with two functions of sensing (touch and strain) was designed by integrating silk fabric and paper-cut ionic hydrogel. | wearable electronics | 89 |

| Song | A designed hybrid crosslinking strategy continuously wet-spins hydrogel fibers, which are transformed into organohydrogel fibers by simple solvent replacement. | wearable electronics | 90 |

| Li | The composite fibers, Ecoflex-polyacrylamide fibers (EPFs), are created through the combination of heterogeneous elastomers and strong interfacial coupling. | wearable electronics | 58 |

| Illeperuma | A new flame retardant material was developed by laminating hydrogel and fabric. | flame-resistant dress | 96 |

| Yu | Hydrogel fabric laminate was developed by using a thermal laminate-sensitive PNIPAAm/SA hydrogel on the surface of the cotton fabric. | flame-resistant dress | 97 |

| A PNIPAAm/SA/PVA composite hydrogel fabric laminate with high strength and antibacterial properties was prepared by adding PVA as the main component of the hydrogel. | flame-resistant dress | 92 | |

| Nie | PAAM/SiO2 nanocomposite hydrogel was filled into the fabric to form a semi interpenetrating structure at the interface, and flame retardant gel/textile composites were prepared. | flame-resistant dress | 98 |

| Qiu | A bullet-proof bicontinuous hydrogel (BH)/ultrahigh-molecular weight polyethylene fabric (UPF) composite was reported. | flexible protective materials | 101 |

| Li | HAP NPs were copolymerized in situ with elastomeric monomers to form hydrogels and the optimal angle was selected to laminate the aramid fabrics. | flexible protective materials | 41 |

| Li | The double-network composite hydrogel is reinforced by plasma grafted polylactic acid melt-blown non-woven fabric and polyethylene glycol dimaleate. | Adsorption | 39 |

| Zhou | a novel Janus photothermal hydrogel-fabric was developed by firmly formatting surface hydrophobized porous photothermal hydrogel on a commercial cotton fabric in large area. | seawater desalination | 105 |

图9 有机水凝胶纤维的设计和制造。(a)有机水凝胶纤维中交联聚合物网络的分子设计以及水凝胶纤维的湿纺过程和分子演化示意图;(b)水凝胶纤维通过置换溶剂制备为有机水凝胶纤维的化学过程;(c)在连续卷筒线轴上收集的单根长纤维的照片;(d)有机水凝胶纤维针织物的示意图和照片[90]Fig.9 Design and fabrication of organohydrogel fibers. (a) Molecular design of hybrid crosslinked polymeric network in organohydrogel fibers and schematic of the wet-spinning process and molecular evolution of hydrogel fibers. (b) Schematic of the preparation of organohydrogel fibers from hydrogel fibers by displacement solvent. (c) Photograph of a long single fiber collected on a continuously winding drum spool. (d) Schematic and photograph of an organohydrogel-fiber knitted textile [90] |

| [1] |

|

| [2] |

|

| [3] |

(于秋灵, 李政, 窦春妍, 赵义平, 巩继贤, 张健飞. 化学进展, 2020, 32(2):179.).

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

(崔烨璇, 仝雅娜, 刘伟东, 李政, 巩继贤, 乔长晟. 材料工程, 2023, 51 (09):37.)

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

| [74] |

|

| [75] |

(杨宇州, 李政, 黄艳凤, 巩继贤, 乔长晟, 张健飞. 化学进展, 2021, 33(05):726.).

|

| [76] |

(窦春妍, 李政, 何贵东, 巩继贤, 刘秀明, 张健飞. 化学进展, 2018, 30(8):1161.).

|

| [77] |

|

| [78] |

|

| [79] |

|

| [80] |

|

| [81] |

|

| [82] |

|

| [83] |

|

| [84] |

|

| [85] |

|

| [86] |

|

| [87] |

|

| [88] |

|

| [89] |

|

| [90] |

|

| [91] |

|

| [92] |

|

| [93] |

|

| [94] |

|

| [95] |

|

| [96] |

|

| [97] |

|

| [98] |

|

| [99] |

|

| [100] |

|

| [101] |

|

| [102] |

|

| [103] |

|

| [104] |

|

| [105] |

|

/

| 〈 |

|

〉 |