Condensed Matter Chemistry: The Defect Engineering of Porous Materials

Received date: 2022-12-01

Revised date: 2023-03-19

Online published: 2023-04-30

Supported by

The 1000 Talents Plan for Young Talents and the National Natural Science Foundation of China(21671073)

The 1000 Talents Plan for Young Talents and the National Natural Science Foundation of China(21621001)

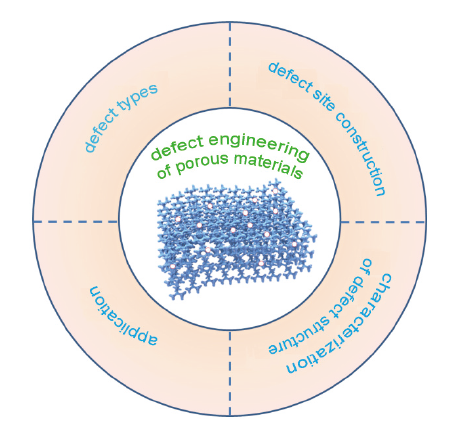

Condensed matter chemistry is mainly concerned with the multilevel structure, chemical properties and chemical reactions of various states of materials, and frontier scientific issues in condensed matter construction chemistry. Porous materials with high surface area and adjustable pore structure, show great potential in a variety of applications. With the continuous exploration of defect engineering strategies for porous materials, the research scope of condensed matter chemistry has been greatly expanded. In the construction of defect sites and the functionalization application of porous materials, condensed matter chemistry permeates every process. The formation and regulation of phase, pore structure and defect sites involved in the synthesis of defective porous materials and the effective transformation of guest species on surface active sites in performance application, which fully reflects various chemical reactions, surface and interface interactions between the microstructure of porous materials and different species in condensed matter chemistry. This paper takes defective porous materials as the research object to discuss, including the suitable inorganic porous materials for defect engineering strategies, the types of defect structures in porous materials, the construction and regulation of defect sites of porous materials in condensed matter chemistry, the characterization of defect sites in porous materials, and applications of defect-rich porous materials in the field of energy storage and catalysis. In is desired to deepen the understanding of porous material defect engineering from the perspective of condensed matter chemistry, and it is expected to further promote the development of functional porous materials under the guidance of condensed matter chemistry.

1 Introduction

2 Porous materials suitable for defect engineering

3 Defect types of porous materials

3.1 Vacancy defect

3.2 Doping defect

3.3 Other type defects

4 Construction methods for defect engineering of porous materials

4.1 In-situ synthesis method

4.2 High temperature heat treatment method

4.3 Chemical reduction method

4.4 Vacuum activation method

4.5 Other methods

5 Characterization method of defect structure in porous materials

5.1 Micromorphology characterization

5.2 X-ray photoelectron spectroscopy

5.3 Raman spectrum

5.4 Electron paramagnetic resonance spectroscopy

5.5 Synchrotron radiation X-ray fine structure spectrum

6 Applications of defect-rich porous materials

6.1 Effect of defect engineering on porous materials

6.2 Application of defect-rich porous materials in catalysis and energy fields

7 Conclusion and perspective

Yuenan Zheng , Jiaqi Yang , Zhen-An Qiao . Condensed Matter Chemistry: The Defect Engineering of Porous Materials[J]. Progress in Chemistry, 2023 , 35(6) : 954 -967 . DOI: 10.7536/PC230102

图4 Vs-M-ZnIn2S4纳米片的:(a)原子力显微镜图片,(b)透射电子显微镜图片,(c)高倍率透射电子显微镜虚拟彩色图片。MoS2QDs@Vs-M-ZnIn2S4纳米片的:(d)透射电子显微镜图片,(e)高倍率透射电子显微镜虚拟彩色图片与(f)高倍率透射电子显微镜图片[78]Fig.4 (a) AFM image (inset is the height profiles of lines 1 and 2), (b) TEM image (inset is HRTEM image), and (c) false-color image of the HRTEM image of Vs-M-ZnIn2S4 nanosheets. (d) TEM image, (e) false-color image of the HRTEM image, and (f) HRTEM image of MoS2QDs@Vs-M-ZnIn2S4 nanosheets[78] |

图6 (a)不同扫描速率下的CV曲线;(b)质量比电容;(c)与报道的多孔碳的重量电容和比表面积的对比结果;(d)与商用活性炭YP-50F相比,在2和10 mg·cm-2的质量负载下的体积电容;(e)5 A·g-1时BSG的循环性能曲线[84]Fig.6 (a) CV curves at various scan rates, (b) gravimetric capacitances, (c) gravimetric capacitance and specific surface area compared with the reported porous carbons (the dotted line is the specific surface area capacitance (Cs)), (d) volumetric capacitances at the mass loadings of 2 and 10 mg·cm-2 compared with commercial activated carbon YP-50F, and (e) cycling performance of BSG at 5 A·g-1[84] |

图7 (a)高N掺杂的二维介孔碳材料的合成示意图;(b)GO@NMC的电化学双层电容和赝电容示意图;(c)不同电流密度下GO@NMC-1的恒流充电/放电曲线[88]Fig.7 (a) Schematic illustration of the synthetic procedure for the development of GO@NMC-1. (b) Schematic illustration of the electrochemical double-layer capacitance (EDLC) and pseudocapacitance of GO@NMC. (c) Galvanostatic charges/discharge curves of GO@NMC-1 at different constant currents[88] |

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

| [74] |

|

| [75] |

|

| [76] |

|

| [77] |

|

| [78] |

|

| [79] |

|

| [80] |

|

| [81] |

|

| [82] |

|

| [83] |

|

| [84] |

|

| [85] |

|

| [86] |

|

| [87] |

|

| [88] |

|

/

| 〈 |

|

〉 |