Flexible Textile Structure Force Sensor

Received date: 2024-01-08

Revised date: 2024-03-26

Online published: 2024-07-01

Supported by

Youth Fund of the National Natural Science Foundation of China(52303119)

Postdoctoral Science Foundation of China(2021M701450)

Key Scientific Research Project in Universities of Henan Province(23A540001)

Henan Province Science and Technology Research Project(242102220096)

Support project for Young Backbone teachers(2023XQG02)

Strength Improvement Program of Advantageous Disciplines of Zhongyuan University of Technology(SD202221)

Strength Improvement Program of Advantageous Disciplines of Zhongyuan University of Technology(SD202222)

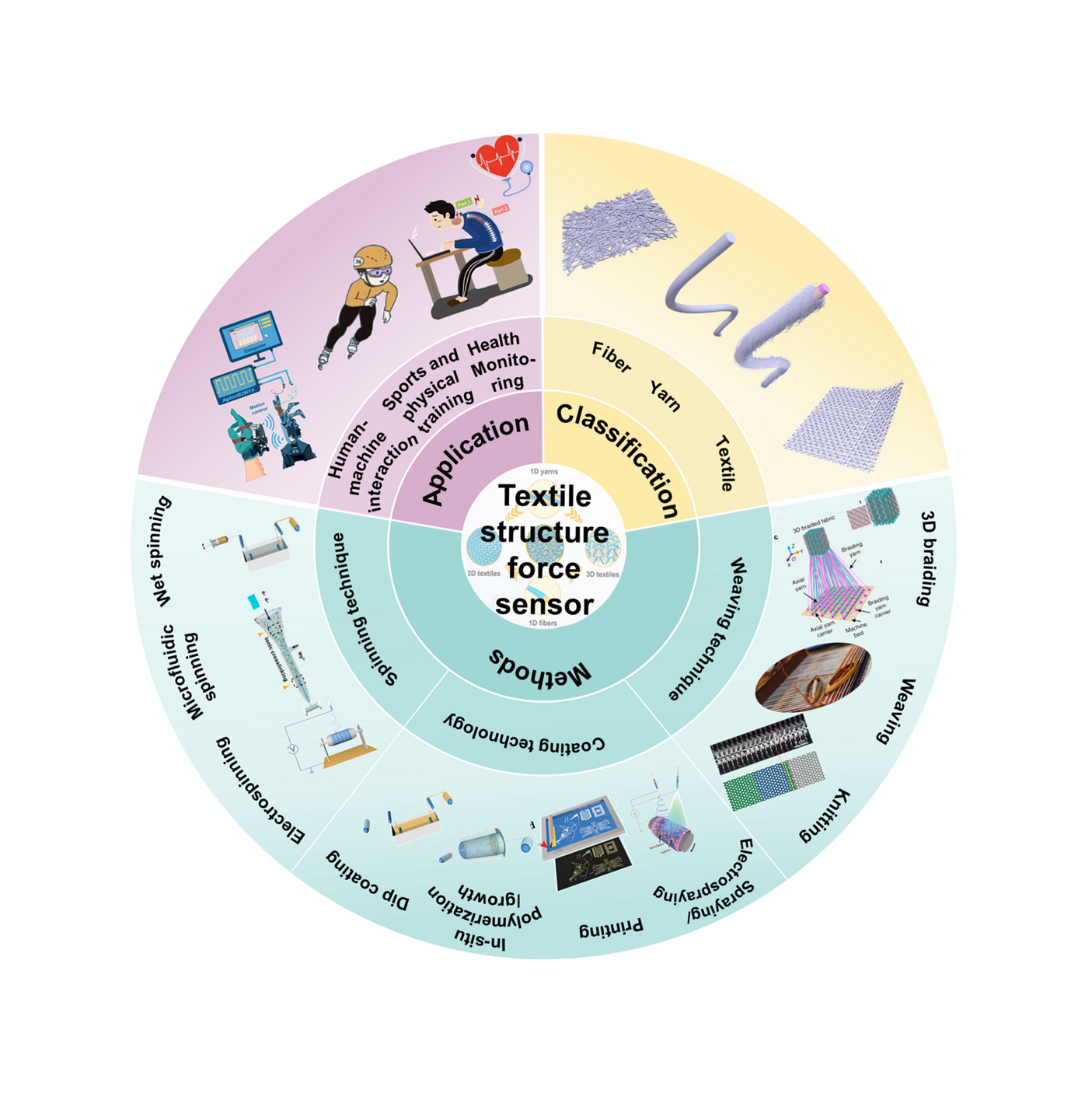

in recent years,the development of material science,micro/nano structure design and processing technology have endowed fibers and textiles with various functions,which promote the wide range of applications in the fields of physiological monitoring,medical diagnosis,tactile perception and human-computer interaction.in order to further promote the application of fiber and textile in the field of wearable devices,this paper reviews the recent research and development status and application of textile structure force sensors recently.Firstly,the textile structure force sensors are classified from fiber,yarn and textile level,and the advantages and disadvantages of different textile structure force sensors are briefly introduced.Secondly,the preparation methods of textile structural force sensors are discussed from preparation techniques,including spinning techniques,coating techniques and textile forming techniques,and the advantages and disadvantages of various preparation methods are discussed.Then,the applications of textile structure force sensors in sports and physical training,health monitoring and human-machine interaction are systematically elaborated.Finally,the future development trend of textile structure force sensors in the field of smart wearables is prospected in the hope of providing a novel way for the research of the next generation of wearable force sensors。

Content

1 Introduction

2 Classification of textile structure force sensor

2.1 Fiber-based force sensor

2.2 Yarn-based force sensor

2.3 Textile-based force sensor

3 Preparation method of textile structure force sensor

3.1 Spinning techniques

3.2 Coating techniques

3.3 Textile forming techniques

4 Application of textile structure force sensor

4.1 Sports and physical training

4.2 Health monitoring

4.3 Human-machine interaction

5 Conclusions and outlook

Kun Qi , Yunling Dai , Kangkang Ou , Mengting Wang , Yu Su , Hongbo Wang . Flexible Textile Structure Force Sensor[J]. Progress in Chemistry, 2024 , 36(8) : 1269 -1282 . DOI: 10.7536/PC240103

图3 静电纺丝技术制备纺织结构力敏传感器:(a,b)静电纺丝技术[43,44];(c)共轭静电纺丝技术[48]Fig. 3 Electrospinning technique for textile structure sensor. (a, b) Electrospinning technique[43,44], Copyright Wiley-VCH GmbH, 2022; Copyright American Chemical Society, 2019. (c) Conjugate electrospinning technique[48], Copyright American Chemical Society, 2022 |

图4 涂层技术制备纺织结构力敏传感器:(a)浸渍技术[52];(b)原位聚合技术[55];(c)原位生长技术[54];(d)印刷技术[59];(e)静电喷雾技术[65]Fig. 4 Coating technique for textile structure sensor. (a) Dip coating technique[52], Copyright The Author(s), 2022. (b) In-situ polymerization technique[55]. (c) In-situ growth technique[54]. (d) Printing technique[59], Copyright Wiley-VCH GmbH, 2022. (e) Electrospraying technique[65], Copyright Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, 2019 |

图6 纺织结构力敏传感器的应用:(a)跳绳训练[73];(b)排球训练[74];(c)脉搏和心跳监测[79];(d)心电信号和肌电信号监测[81];(e)手势-语音翻译系统[84];(f)无线控制系统[64]Fig. 6 Application of textile structure sensor. (a) Jump rope training[73], Copyright Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, 2018. (b) Volleyball training[74], Copyright American Chemical Society, 2021. (c) Pulse and heartbeat monitoring[79], Copyright The Authors, 2020. (d) ECG and EMG monitoring[81], Copyright Wiley‐VCH GmbH, 2022. (e) Gesture-to-speech translation system[84]. (f) Wireless control system[64], Copyright American Chemical Society, 2021 |

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

(孙华悦, 向宪昕, 颜廷义, 曲丽君, 张光耀, 张学记, 化学进展, 2022, 34(12):2604.)

|

| [7] |

(王雨柔, 王国琪, 李想, 尹君, 朱剑. 化学学报, 2022, 80(2):15.)

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

何崟, 田福君, 王晓云, 刘皓, 刘莉. 棉纺织技术, 2022, 50(6): 1.

|

| [12] |

|

| [13] |

(王霁龙, 刘岩, 景媛媛, 许庆丽, 钱祥宇, 张义红, 张坤, 纺织学报, 2020, 41(12):157.)

|

| [14] |

|

| [15] |

|

| [16] |

(夏磊, 汤清伦, 韦炜, 棉纺织技术, 2022, 50(04):73.)

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

(聂文琪, 许帅, 孙江东, 储长流, 徐珍珍. 高分子通报, 2022, (12):99.)

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

(王航, 王冰心, 宁新, 曲丽君, 田明伟. 纺织学报, 2021, 42(6): 189.)

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

| [74] |

|

| [75] |

|

| [76] |

|

| [77] |

|

| [78] |

|

| [79] |

|

| [80] |

|

| [81] |

|

| [82] |

|

| [83] |

|

| [84] |

|

| [85] |

|

/

| 〈 |

|

〉 |