Design and Application of Multifunctional Infrared Stealth Materials

Received date: 2024-01-30

Revised date: 2024-05-04

Online published: 2024-07-01

Supported by

National Natural Science Foundation of China(22378253)

National Natural Science Foundation of China(22078188)

Natural Science Basic Research Program of Shaanxi(2024JC-YBMS-122)

Xianyang Scientific and Technological Projects(2021ZDZX-GY-0007)

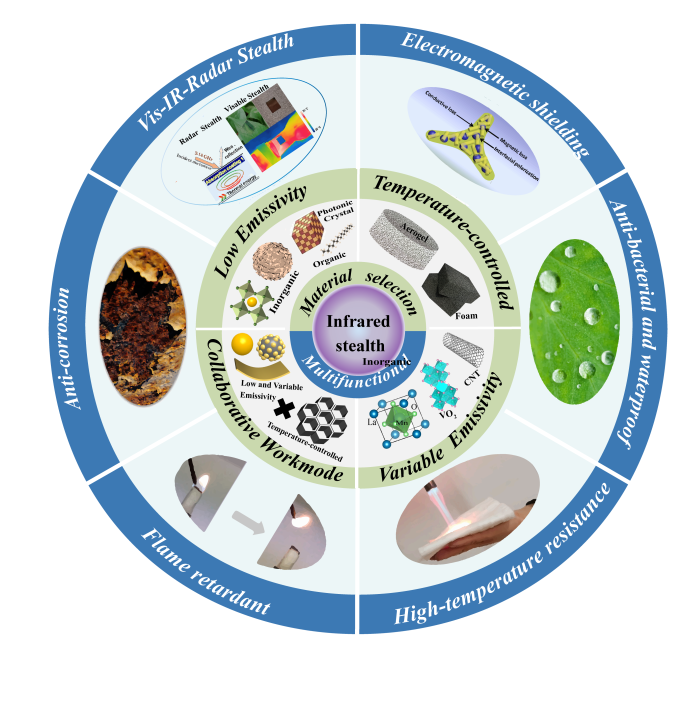

the rapid development of infrared detection equipment has caused a huge threat to military equipment.and infrared stealth technology is an important way to improve the survival,strike and breakthrough capabilities of military equipment,and plays a vital role In the development of the national defense industry.However,the battlefield environment is complex and changeable,and materials with only infrared stealth performance are difficult to meet the actual needs when facing radar detection,rainforest,mountain,ocean,desert and other environments.Therefore,it is imperative to develop multifunctional infrared stealth materials.in this paper,the latest research progress of different infrared stealth materials is reviewed from the perspective of the mechanism of infrared stealth materials,such as low emissivity materials,temperature control materials,variable emissivity materials and cooperative working mode materials,and the control methods of different infrared stealth materials are discussed.Secondly,the multi-functional infrared stealth materials suitable for different application scenarios,such as multi-band stealth,electromagnetic shielding,antibacterial and waterproof,high temperature resistance,anti-corrosion and flame retardant infrared stealth materials,and their design mechanisms are discussed.Finally,the future development of multifunctional infrared stealth materials is summarized and prospected。

1 Introduction

2 Infrared stealth mechanisms

3 Selection and performance control of infrared stealth materials

3.1 Low emissivity materials

3.2 Temperature-controlled materials

3.3 Variable emissivity materials

3.4 Collaborative work mode materials

4 Design and application of multifunctional infrared stealth materials

4.1 Multi-band stealth

4.2 Electromagnetic shielding

4.3 Antibacterial and waterproof properties

4.4 High temperature resistance

4.5 Flame retardant properties

4.6 Anti-corrosion properties

5 Conclusion and outlook

Sike Yu , Yan Bao , Lu Gao , Wenbo Zhang . Design and Application of Multifunctional Infrared Stealth Materials[J]. Progress in Chemistry, 2024 , 36(9) : 1349 -1362 . DOI: 10.7536/PC240126

表1 Advantages and Disadvantages of Infrared Stealth MaterialsTable 1 Advantages and disadvantages of infrared stealth materials |

| Classify | Material | Advantage | Disadvantage | Ref | ||

|---|---|---|---|---|---|---|

| Low Emissivity | Inorganic | Metal (Au、Ag、Cu、Al) | Good conductivity and low emissivity | It is easy to corrode, has a strong metallic luster, and is difficult to be compatible with visible light | 6⇓⇓⇓~10 | |

| Semiconductor (ATO、ZAO、ITO) | Corrosion-resistant, bandgap and structure can be adjusted, and it can be used in a wide range of applications | High emissivity | 13⇓~15 | |||

| Organic | Conducting polymers | Excellent electrical conductivity | Less research work | 17,18,20 | ||

| High infrared transparent polymers | Weak infrared absorption group | High emissivity | 21 | |||

| Organic-inorganic | Excellent mechanical properties; Low emissivity | Many influencing factors | 22⇓⇓⇓~26 | |||

| Photonic crystals | Adjustable bandgap | The high cost of preparation does not allow large-scale use | 28,29,32,33 | |||

| Temperature-controlled materials | Thermal insulation | Effective, with a wide range of applications | The preparation process is complex, the thickness is large, and the temperature control range is limited | 38,40⇓⇓⇓⇓⇓⇓⇓⇓⇓⇓⇓⇓~53 | ||

| Phase change | VO2 | The amount of change is large, and the phase change temperature is adjustable | The color is blue-black, which is difficult to achieve compatibility with visible light and stealth; It is easy to oxidize to the toxic oxide V2O5 at high temperatures | 58⇓⇓~61 | ||

| PW | Stable performance, the change in phase change temperature and latent heat of phase change is small | Adding too much PW can lead to a decrease in mechanical properties | 63 | |||

| MCPCM | Improve the leakage problem of solid-liquid phase change materials | Single core material and expensive | 64 | |||

| Variable emissivity material | Electro-emissivity materials | The emissivity can be adjusted in a wide range | There is additional energy consumption for the impressed load | 66⇓~68 | ||

| Thermotropic emissivity materials | No external load is required, no energy consumption is required, and it varies according to its own surface temperature | The response sensitivity is slower, and the emissivity can be adjusted in a small range | 70⇓~72 | |||

| Collaborative work mode material | Temperature control, low emissivity | It solves the poor thermal insulation performance of low emissivity materials; High emissivity of temperature-controlled materials and problems with heat build-up | There are few studies on materials where temperature and emissivity can change | 73⇓⇓~76 | ||

| Temperature control, variable emissivity | Temperature and emissivity can be adjusted for a wider range of applications | 77 | ||||

表2 Performance parameters of radar-infrared compatible stealth materialTable 2 Performance parameters of radar infrared compatible stealth materials |

| Sample | Emissivity | Electromagnetic parameters | Ref | ||||

|---|---|---|---|---|---|---|---|

| 3~5 μm | 8~14 μm | RLmin (dB) | EAB (GHz) | RCS (dB·m2) | Thickness (mm) | ||

| ITO-x | 0.62 | 0.67 | -40.4 | 4.88 | - | 2.8 | 14 |

| Al@RGO | - | 0.62 | -46.11 | 4.88 | - | 2 | 79 |

| Al/CIP-PU | 0.281 | - | -40 | 6.6 | - | 1.24 | 80 |

| CuS/ZnS/rGO | 0.694 | 0.577 | -28 | 6.38 | 2 | 26.3 | 81 |

| Au @MCHSs/CA-2 | 0.525 | - | -55.9 | 16 | 21.5 | 1.8 | 82 |

| CuS@rGO | 0.7 | 0.6 | -60.3 | 8.44 | 53.3 | 2.8 | 84 |

| PEDOT:PSS@melamine | 0.788 | 0.757 | -57.57 | 10.52 | 17.68 | 5 | 85 |

| HMCS@f-Fe2O3-x | 0.212 | 0.508 | -34.16 | 4.8 | - | 2.4 | 86 |

图7 (a)HGC气凝胶制备的示意图;(b)灭火过程中,HGC气凝胶的氧浓度为28.2%;(c)HGC气凝胶放置在80 ℃的加热平台上60 min红外热成像图[100]Fig. 7 (a) Schematic diagram of the HGC aerogel formulation; (b) Extinguishing process of the HGC aerogel in the oxygen concentration of 28.2%; (c) HGC aerogel was placed on a heating platform at 80 ℃ for 60 min infrared thermography[100] |

| [1] |

(王万安, 张飞飞, 景卓元, 姜孝天, 辛昊. 印染, 2022, 48(12): 74.).

|

| [2] |

(田昌会, 蔡明, 王斌科, 范琦, 杨百愚, 王伟宇, 屈绍波. 空军工程大学学报(自然科学版), 2013, 14(4): 81.).

|

| [3] |

(李波. 中国光学, 2013, 6(6): 818.)

|

| [4] |

(巫雪玉. 电子科技大学博士论文, 2021).

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

(王硕, 孙志一. 针织工业, 2020, (5): 40.)

|

| [9] |

(王田宇, 卞进田, 李欣, 孔辉, 孙晓泉. 中国激光, 2021, 48 (04): 269.).

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

(江文杰. 东华大学硕士论文, 2016.) .

|

| [22] |

|

| [23] |

(孙瑞, 何效凯, 高萌, 黄震, 魏乃影. 中国涂料, 2016, 31(06): 59.).

|

| [24] |

(夏继余. 红外技术, 1988, 10(1): 10.).

|

| [25] |

|

| [26] |

|

| [27] |

(孟真, 李广德, 崔光振, 王义, 刘东青. 材料导报, 2023, 37(21): 5.).

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

(卢仪, 卜小海, 李栋先, 刘飞佑, 张泽武. 激光与光电子学进展, 2019, 56(08): 32.).

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

(叶星云. 兰州理工大学硕士论文, 2022).

|

| [56] |

(饶中浩, 汪双凤, 张艳来, 彭飞飞, 蔡颂恒. 物理学报, 2013, 62(5): 331.).

|

| [57] |

(吴燕飞. 中国科学技术大学博士论文, 2014).

|

| [58] |

|

| [59] |

|

| [60] |

(孙恒辉, 雷心瑜, 袁新强, 蒋鹏, 张伟, 张立斋. 材料热处理学报, 2023, 1.).

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

(王信刚, 刘世成, 雷为愉, 张晨阳. 材料导报, 2023, 36(24): 21090229-5.)

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

(刘嘉玮, 王建江, 赵芳, 许宝才. 高等学校化学学报, 2017, 38(6): 929.).

|

| [73] |

|

| [74] |

|

| [75] |

|

| [76] |

|

| [77] |

|

| [78] |

(郭腾超. 南京航空航天大学博士论文, 2023).

|

| [79] |

|

| [80] |

|

| [81] |

|

| [82] |

|

| [83] |

|

| [84] |

|

| [85] |

|

| [86] |

|

| [87] |

|

| [88] |

|

| [89] |

|

| [90] |

|

| [91] |

|

| [92] |

|

| [93] |

|

| [94] |

|

| [95] |

|

| [96] |

|

| [97] |

|

| [98] |

|

| [99] |

|

| [100] |

|

| [101] |

|

| [102] |

|

/

| 〈 |

|

〉 |