Construction of Biomass-Based Sensors and Their Application in Human Health Monitoring

Received date: 2024-01-29

Revised date: 2024-06-27

Online published: 2024-08-30

Supported by

National Natural Science Foundation of China(52073164)

National Natural Science Foundation of China(21908141)

Natural Science Basic Research Program of Shaanxi(2024JC-YBMS-122)

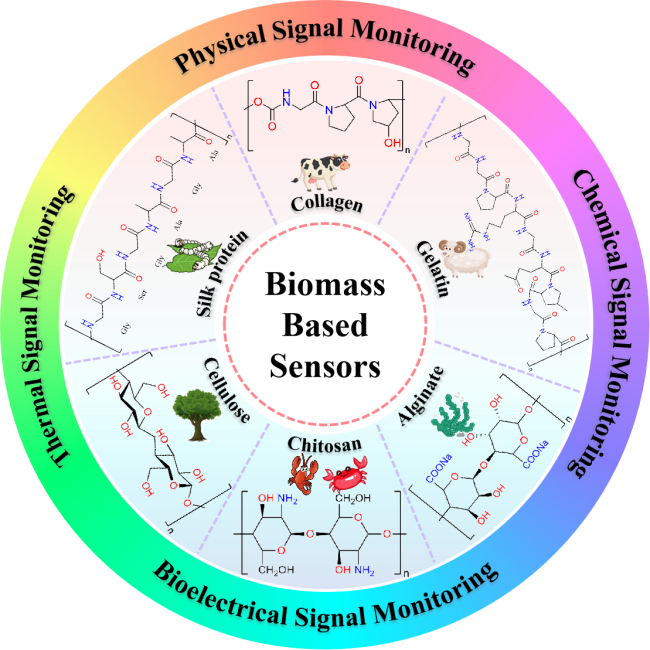

with the continuous development of flexible electronic devices in recent years,flexible wearable sensors show great potential for development in the fields of human health monitoring,electronic skin,and intelligent machines.biomass materials,as a kind of renewable resource derived from living organisms with excellent characteristics such as inexpensive,green and,eco-friendly,skin-friendly and breathable,and good biocompatibility,have been heavily studied as the matrix of wearable,flexible sensors.biomass-based sensors can be ideal for use in the field of human health monitoring because they combine the excellent properties of biomass materials with sensing elements.This paper first reviews the structure,composition and working principle of common flexible sensors(strain,pressure,temperature,biological).and then,the characteristics of different biomass-based sensors and their applications are described in detail.the biomass materials involved mainly include collagen,gelatine,cellulose,chitosan,sodium alginate,and silk protein.in addition,the applications of biomass-based sensors in human health monitoring(including physical signals,chemical signals,bioelectrical signals and thermal signals monitoring)are summarised.Finally,the challenges and future directions of biomass-based sensors and their applications in the field of human health monitoring are pointed out in light of the current status of the applications they are currently facing。

1 Introduction

2 Classification and principles of flexible sensors

2.1 Flexible strain sensors

2.2 Flexible pressure sensors

2.3 Flexible temperature sensors

2.4 Flexible biosensors

3 Biomass-based flexible sensor

3.1 Collagen-based sensor

3.2 Gelatin-based sensor

3.3 Sodium alginate-based sensor

3.4 Cellulose-based sensor

3.5 Chitosan-based sensor

3.6 Silk protein-based sensor

4 Application of biomass-based sensors in human health monitoring

4.1 Physical signal monitoring

4.2 Chemical signal monitoring

4.3 Bioelectrical signal monitoring

4.4 Thermal signal monitoring

5 Conclusion and outlook

Key words: flexible sensor; biomass-based sensors; health monitoring; wearable

Huiyuan Liang , Jianzhong Ma , Jian Yang , Wen Li , Wenbo Zhang . Construction of Biomass-Based Sensors and Their Application in Human Health Monitoring[J]. Progress in Chemistry, 2024 , 36(9) : 1380 -1391 . DOI: 10.7536/PC240125

| [1] |

(岳欧阳. 陕西科技大学博士论文, 2023.).

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

(马振萍, 谢智晖, 陈卓, 王盛冀, 柏凯健, 夏志柯, 经鑫. 功能材料与器件学报, 2021, 27(03): 165.).

|

| [11] |

(潘朝莹, 马建中, 张文博, 卫林峰. 化学进展, 2020, 32(10): 1592.).

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

(门海蛟, 宋健尧, 黄秉经, 李建昌. 材料导报, 2023, 37(21): 45.).

|

| [17] |

|

| [18] |

(王锐. 东北电力大学博士论文, 2023.).

|

| [19] |

(鲍艳, 许佳琛, 郭茹月, 马建中. 化学进展, 2023, 35(05): 709.).

|

| [20] |

(徐娜, 王国栋, 陶亚楠. 化工进展, 2023, 42(10): 5259.).

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

(谈溥川, 赵超超, 樊瑜波, 李舟. 物理学报, 2020, 69(17): 143.).

|

| [28] |

|

| [29] |

(白忠薛, 王学川, 冯宇宁, 冯练享, 李佳俊, 李彤, 潘伟佳, 刘新华. 精细化工, 2023, 40(11): 2357.).

|

| [30] |

|

| [31] |

(吉静, 黄明智. 明胶科学与技术, 2001, (01): 12.).

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

(华冰艳. 河南工业大学博士论文, 2023.).

|

| [53] |

|

| [54] |

|

| [55] |

(陈凯伦. 浙江大学博士论文, 2022.).

|

| [56] |

(冯华伟. 安徽理工大学博士论文, 2020.).

|

| [57] |

(高雪. 青岛科技大学博士论文, 2021.).

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

(黄彪, 林凤采, 唐丽荣, 卢麒麟, 卢贝丽. 林业工程学报, 2022, 7(02): 1.)

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

| [74] |

|

| [75] |

|

| [76] |

|

| [77] |

|

| [78] |

|

| [79] |

|

| [80] |

|

| [81] |

|

| [82] |

|

| [83] |

(冯荣欣, 但年华, 陈一宁. 材料导报, 2023, 37(14): 248.)

|

| [84] |

|

| [85] |

|

| [86] |

|

| [87] |

|

| [88] |

|

| [89] |

|

| [90] |

|

| [91] |

|

| [92] |

|

| [93] |

|

| [94] |

|

| [95] |

|

| [96] |

|

| [97] |

|

| [98] |

|

| [99] |

|

| [100] |

|

| [101] |

|

| [102] |

|

| [103] |

|

| [104] |

|

| [105] |

|

| [106] |

|

| [107] |

|

| [108] |

|

| [109] |

|

| [110] |

|

| [111] |

|

| [112] |

|

| [113] |

|

| [114] |

(邵子雯, 徐翔宇, 陈伟杰, 蔡佳, 张恒. 电子制作, 2023, 31(18): 39.)

|

| [115] |

|

| [116] |

(刘程林, 郝卫亚, 霍波. 力学进展, 2023, 53(01): 198.)

|

| [117] |

|

| [118] |

|

| [119] |

|

| [120] |

|

| [121] |

|

| [122] |

|

| [123] |

|

| [124] |

|

/

| 〈 |

|

〉 |