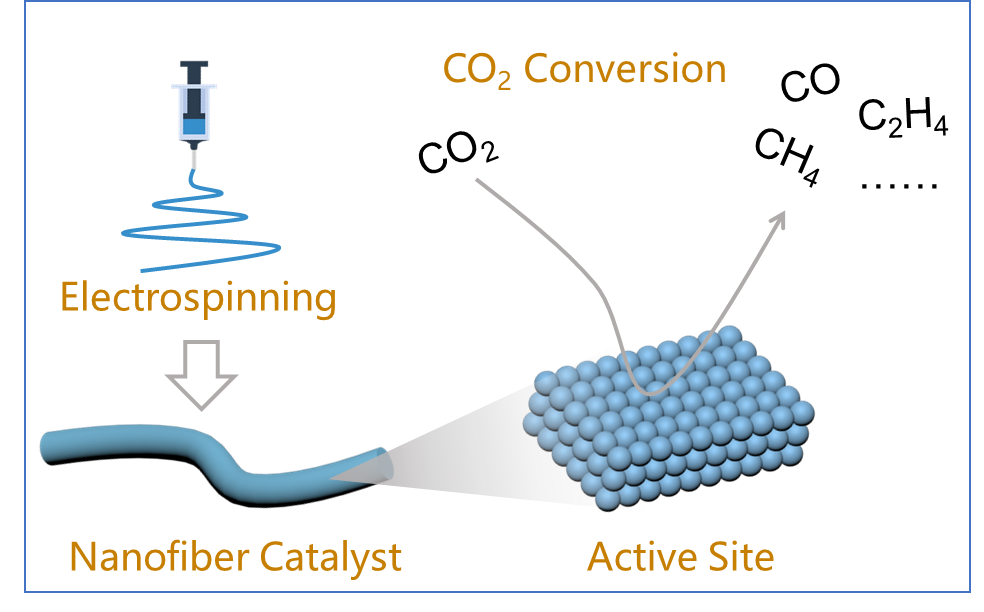

Structural Design and Applications in CO2 Conversion of Electrospun Nanofiber Catalyst

Received date: 2024-10-14

Revised date: 2025-01-03

Online published: 2025-03-20

Supported by

National Natural Science Foundation of China(52172080)

Basic Research Funds for University Directly under the Inner Mongolia Autonomous Region(JY20250034)

Research Initiation Fund of Inner Mongolia University of Technology(BS2025005)

MOE Key Laboratory of Resources and Environmental System Optimization,North China Electric Power University(KLRE-KF 202307)

Using catalytic processes to convert CO2 into low-carbon fuels and fine chemicals is one of the most efficient paths to addressing global energy imbalance and CO2 excess emissions. The advantages of one-dimensional nanocatalysts in long-range electron transport and controllable internal structure endow them with widely utilization in catalysis. Electrospinning,a top-down method for fabrication of fibers,offers unique advantages in regulating fiber composition and structure. This paper systematically reviews the designing strategies and application advancements of fiber catalysts based on electrospinning,including fully controllable synthesis strategies for multilevel structured fibers,methods for introducing active sites via one-step and post-load techniques,and research case of fiber catalysts in CO2 conversion. This review provides valuable references for the development of new concepts,methods,processes,and applications of fiber catalysts for CO2 conversion.

Contents

1 Introduction

2 Electrospinning in designing of fiber catalysts

2.1 Electrospinning

2.2 Designing of fiber structures

2.3 Introducing of active sites

3 Applications of fiber catalysts in CO2 conversion

3.1 Photocatalytic CO2 conversion

3.2 Electrocatalytic CO2 conversion

3.3 Thermocatalytic CO2 conversion

4 Conclusion and outlook

Key words: nanocatalyst; electrospinning; active site; CO2 conversion

Guichu Yue , Yaqiong Wang , Jie Bai , Yong Zhao , Zhimin Cui . Structural Design and Applications in CO2 Conversion of Electrospun Nanofiber Catalyst[J]. Progress in Chemistry, 2025 , 37(4) : 508 -518 . DOI: 10.7536/PC241004

图3 (a)中空通孔WO3纤维[31],(b)多孔TiO2纤维[32],(c)三通道TiO@NC纤维[33],(d)管套线TiO2纤维[34],(e)管套管SnO2纤维[35],(f)MoS2@TiO2纤维[36]Fig.3 (a) Hollow through-holes WO3 fiber[31],Copyright 2016,Royal Society of Chemistry;(b) Porous TiO2 fiber[32],Copyright 2011,Wiley;(c) Triple channels TiO@NC fiber[33],Copyright 2022,Springer;(d) Wire-in-tube TiO2 fiber[34],Copyright 2010,American Chemical Society;(e) Tube-in-tube SnO2 fiber[35],Copyright 2020,Wiley;(f) MoS2@TiO2 fiber[36],Copyright 2024,Wiley |

图7 (a)白色Nb2O5纤维SEM图,(b)室温缺陷控制策略,(c)黑色Nb2O5-x纤维TEM图,(d)Nb2O5和Nb2O5-x纤维的EPR表征,(e)光催化CO2还原的选择性,(f)黑色Nb2O5-x纤维膜集成的光催化器件[55]Fig.7 (a) SEM image of white Nb2O5 fiber,(b) Construction strategy of room-temperature defect,(c) TEM image of black Nb2O5-x fiber,(d) EPR spectra of Nb2O5 and Nb2O5-x fiber,(e) Selectivity of photocatalytic CO2 reduction,(f) Photocatalytic model device integrated with black Nb2O5-x fiber film[55],Copyright 2022,Wiley |

图8 (a)HESO纤维合成策略,(b,c)HESO纤维的TEM和反傅里叶变换结果,(d,e)HESO催化CO2转化的in situ DRIFTS和产量,(f)CO2转化的反应路径[57]Fig.8 (a) Synthetic strategy of HESO fibers,(b,c) TEM and inverse Fourier Transform results of HESO,(d,e) in situ DRIFTS and products of CO2 conversion catalyzed by HESO,(f) Reaction path of CO2 conversion[57],Copyright 2024,American Chemical Society |

图9 (a)纳米纤维-介质热力学驱动原子迁移策略,(b)NiSA-VC/NCNFs的TEM结果,(c)不同样品的Ni K-edge FT-EXAFS谱,(d)不同样品的FECO,(e)基于单原子催化剂的CO2→CO催化剂性能对比,(f)NiSA-VC/NCNFs催化过程的in situ ATR-SEIRAS谱,(g)不同样品催化CO2→CO过程的ΔG[69]Fig.9 (a) nanofiber-medium thermodynamically driven atomic migration strategy,(b) TEM result of NiSA-VC/NCNFs,(c) Ni K-edge FT-EXAFS spectra of different samples,(d) FECO of different samples,(e) Comparison of catalytic property of single atomic catalyst for CO2→CO,(f) in situ ATR-SEIRAS spectra of NiSA-VC/NCNFs in catalytic process,(g) ΔG of different samples in CO2→CO process[69],Copyright 2023,American Chemical Society |

图10 (a)催化剂制备流程,(b)NiNF-1100的HAADF-STEM结果,(c)不同样品的FT-EXAFS结果,(d)不同样品的CO和H2法拉第效率,(e)NiNF-1100的循环稳定性,(f)失活原因分析[73]Fig.10 (a) Scheme of the fabrication process of catalyst,(b) AC-HAADF-STEM result of NiNF-1100,(c) FT-EXAFS results of different samples,(d) FECO和 of different samples,(e) recycle stability of NiNF-1100,(f) Failure analysis of NiNF-1100[73],Copyright 2023,Royal Society of Chemistry |

图11 (a)NiNPs@CeO2NFs的TEM图片,(b)不同样品的CO2-TPD结果,(c)不同样品的温度-CO2转化率关系图,(d)不同样品的循环稳定性,(e)NiNPs@CeO2NFs的结构稳定性,(f,g)in situ DRIFTS和in situ Raman结果[77]Fig.11 (a) TEM image of NiNPs@CeO2NFs,(b) CO2-TPD results of different samples,(c) Temperature-CO2 conversion diagram of different samples,(d) Recycling stability of different samples,(e) Structural stability of NiNPs@CeO2NFs,(f,g) in situ DRIFTS and in situ Raman results[77],Copyright 2022,Elsevier |

图12 (a)HEOs纤维制备示意图,(b)(Ni3MoCoZn)Al12O24的TEM和EDS表征结果,(c)100 h内的CO2转化率,(d)不同样品的EPR表征,(e)(Ni3MoCoZn)Al12O24催化过程的in situ DRIFTS结果[80]Fig.12 (a) Scheme of the fabrication process of HEOs fibers,(b) TEM and EDS results of (Ni3MoCoZn)Al12O24,(c) CO2 conversion within 100 h,(d) EPR results of different samples,(e) in situ DRIFTS result of (Ni3MoCoZn)Al12O24 in catalytic process[80],Copyright 2024,American Chemical Society |

表1 不同纤维催化剂用于CO2转化的催化性能对比[55,57,69,73,77,80]Table 1 Catalytic performance comparison of different fiber catalysts in CO2 conversion[55,57,69,73,77,80] |

| Fiber catalyst | Product | Performance descriptor | ref |

|---|---|---|---|

| Nb2O5-x | CH4 | 64.8% of selectivity 19.5 μmol·g-1·h-1 of yield rate | 55 |

| (NiCuMnCoZnFe)3O4 | CO | 66.4% of selectivity 15.89 μmol·g-1·h-1 of yield rate | 57 |

| NiSA-VC/NCNFs | CO | FECO=99.2% at -0.98 vs REH | 69 |

| NiNF-1100 | CO | FECO=95% at 282 mA·cm-2 of jCO | 73 |

| NiNPs@CeO2NFs | CH4 | 83.7% of conversion 98.2% of selectivity | 77 |

| (Ni3MoCoZn)Al12O24 | H2/CO | >99% of conversion H2/CO~1 | 80 |

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

(马思畅, 李东阳, 徐睿. 化学进展, 2024, 36(5):757.).

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

(林刚, 张媛媛, 刘健. 化学进展, 2022, 34(11): 2351.).

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

(于江波, 于婧, 刘杰, 吴占超, 匡少平. 化学进展, 2024, 36(1): 95.).

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

| [74] |

|

| [75] |

|

| [76] |

|

| [77] |

|

| [78] |

|

| [79] |

|

| [80] |

|

/

| 〈 |

|

〉 |