Covalent Organic Frameworks for Photocatalytic CO2 Reduction

Received date: 2022-10-02

Revised date: 2022-10-28

Online published: 2023-02-20

Supported by

National Natural Science Foundation of China(21871141)

National Natural Science Foundation of China(21871142)

National Natural Science Foundation of China(22071109)

National Natural Science Foundation of China(21901122)

National Natural Science Foundation of China(22105080)

National Natural Science Foundation of China(22201083)

China Postdoctoral Science Foundation(2020M682747)

China Postdoctoral Science Foundation(2021M701270)

Guangdong Basic and Applied Basic Research Foundation(2023A1515010779)

Guangdong Basic and Applied Basic Research Foundation(2023A1515010928)

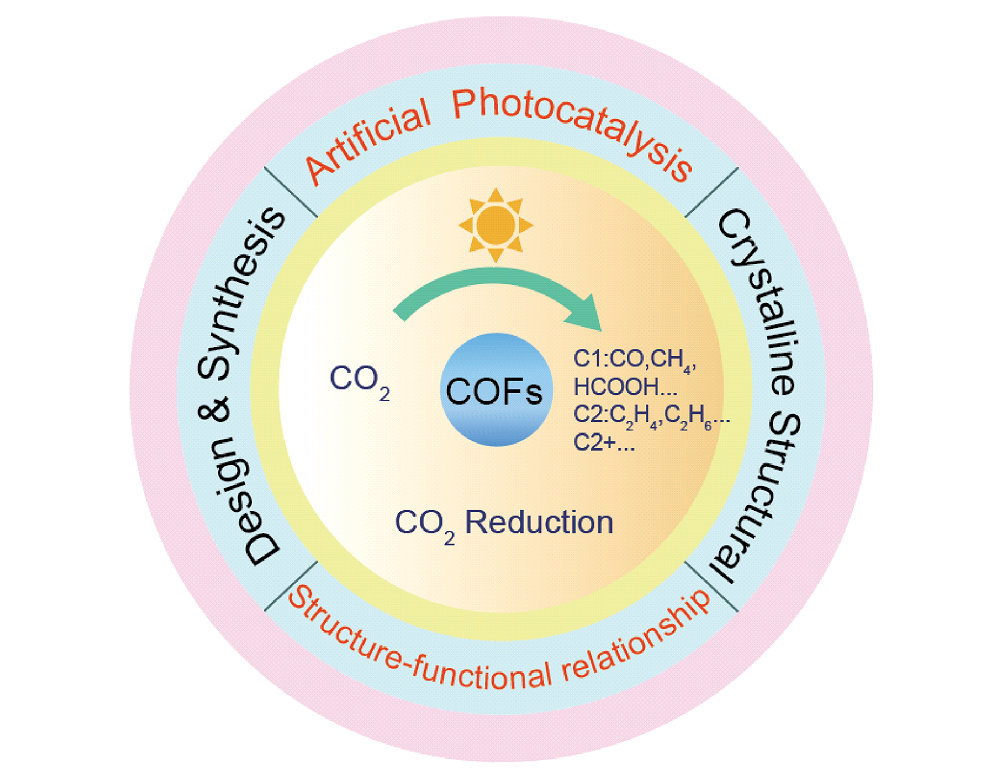

With the massive global consumption of fossil fuels, the energy crisis is getting worse and the emission of greenhouse gases such as CO2 has made the environmental problems become increasingly prominent. Photocatalytic reduction of CO2 to energy compounds is considered to be one of the best ways to effectively solve this problem. Covalent organic frameworks (COFs) are a new type of crystalline porous organic polymer materials with high stability and pre-design ability, which makes COFs own great potential ability in the field of photocatalytic CO2 reduction. This paper summarizes the research progress of COFs in the field of photocatalytic CO2 reduction, including the introduction of different metal ions to provide the active site and increasing the photosensitive functional groups to improve their utilization of visible light. Since the research of COFs as photocatalytic CO2 reduction catalyst is still an initial field, further exploration of synthesis, modification, and mechanism of COFs for CO2 reduction is still promising research work.

Liu Yvfei , Zhang Mi , Lu Meng , Lan Yaqian . Covalent Organic Frameworks for Photocatalytic CO2 Reduction[J]. Progress in Chemistry, 2023 , 35(3) : 349 -359 . DOI: 10.7536/PC220936

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

(路猛. 南京师范大学博士论文, 2021.).

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

(王玉杰, 岳喜龙, 吴彤, 怀燕瑾, 程庆霖, 张曼莹. 能源环境保护, 2022, 36(2): 52.).

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

/

| 〈 |

|

〉 |