Research Progress and Application of Flexible Thermoelectric Materials

Received date: 2022-08-15

Revised date: 2022-09-29

Online published: 2023-02-20

Supported by

National Natural Science Foundation of China(51501014)

2021 Beijing Undergraduates Research Training Program(2021J00057)

2022 National Undergraduates Research Training Program of China

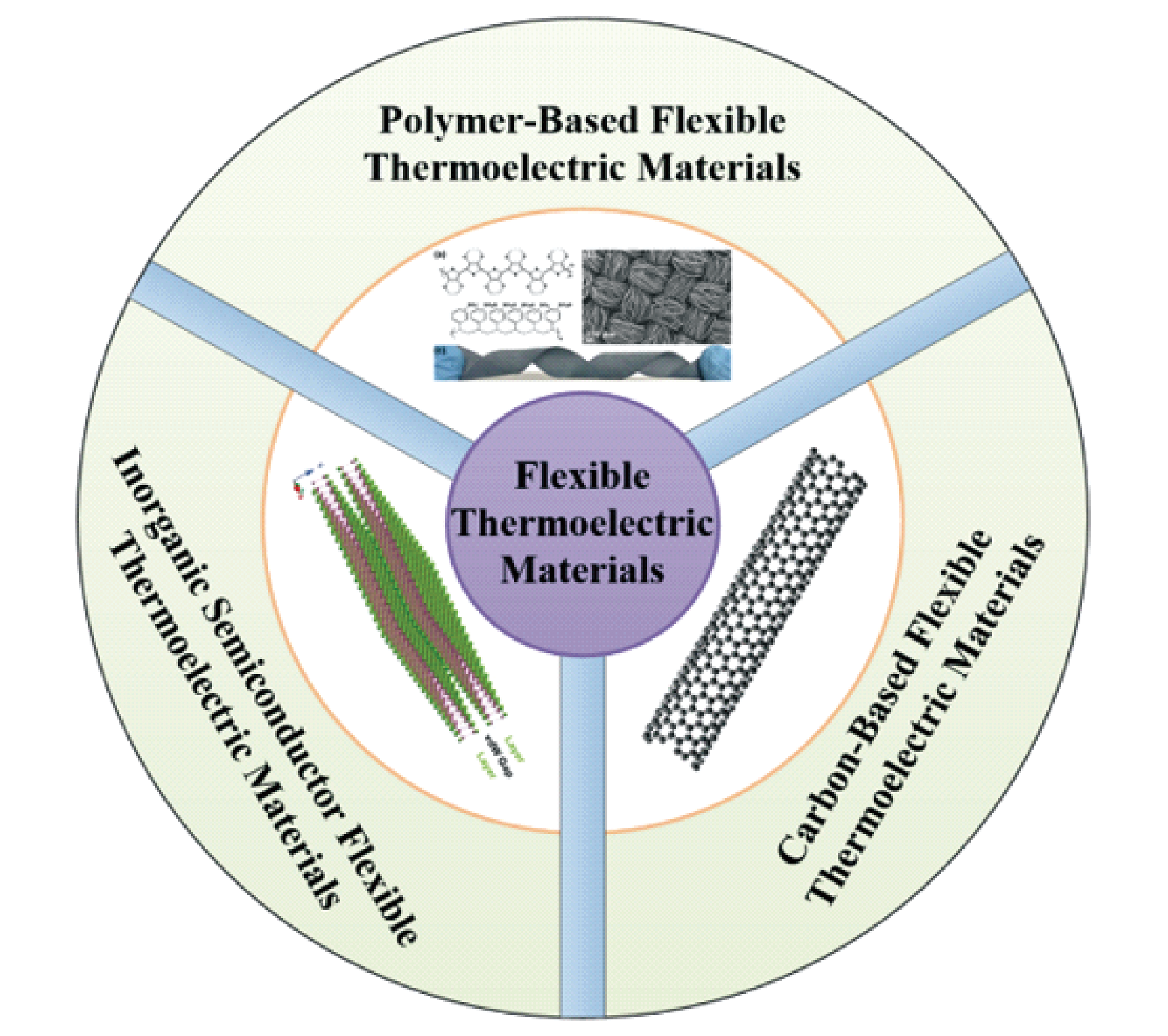

Thermoelectric materials, as one new kind of energy materials, can realize the direct conversion of thermal and electrical energy, which have important applications in power generation and refrigeration. Compared with traditional thermoelectric materials, flexible thermoelectric materials demonstrate excellent application prospects in wearable devices and flexible electronics fields, due to the advantages of being bendable, a lightweight and environmentally friendly. At present, how to further improve the performance of flexible thermoelectric materials is the focus, especially the collaborative optimization of flexibility andthermoelectric properties. In this paper, we have reviewed the research progress of polymer-based flexible thermoelectric materials, carbon-based flexible thermoelectric materials and inorganic semiconductor flexible thermoelectric materials, introduced their characteristics, performance optimization and preparation methods, and summarized the applications of flexible thermoelectric materials in the fields of electronics, medicine and industry. Also, based on the shortcomings of flexible thermoelectric materials, the future research directions are prospected.

Dong Baokun , Zhang Ting , He Fan . Research Progress and Application of Flexible Thermoelectric Materials[J]. Progress in Chemistry, 2023 , 35(3) : 433 -444 . DOI: 10.7536/PC220812

图2 (a)PEDOT:PSS类纸状薄膜的柔韧性;(b)室温下柔性PEDOT:PSS类纸状薄膜掺杂不同物质后的电学性能[21];SnSe纳米片/PEDOT:PSS复合材料在室温下的Seekbeck系数(c)和ZT值(d)随SnSe纳米片含量的变化[36]Fig. 2 (a)Flexibility of PEDOT:PSS bulky papers;(b)Electrical properties of flexible PEDOT:PSS bulky paper doped with different substances[21];Seekbeck coefficient (c) and ZT value (d) of SnSe nanosheets/PEDOT:PSS composites with various of SnSe nanosheet contents at room temperature[36] |

图5 (a)银硫族化合物的柔韧性-ZT值相图;(b)Ag2S基柔性热电材料的ZT值随温度的变化;(c)Ag2S0.5Se0.5的柔韧性;(d)Ag2S0.5Se0.5制作的柔性热电器件[30]Fig. 5 (a)The flexibility-ZT value phase diagram of silver chalcogenides;(b)Temperature dependence of ZT value of Ag2S-based FTE materials;(c)Flexibility of Ag2S0.5Se0.5;(d)FTE device fabricated by Ag2S0.5 30 |

图7 (a)AgCu(Se,S,Te)伪三元固溶体成分-性能相图;(b)AgCuSe基柔性热电材料的ZT值随温度的变化;(c)AgCuSe0.22S0.08Te0.7的柔韧性;(d)AgCuSe0.22S0.08Te0.7制作的柔性热电器件[73]Fig. 7 (a)Compositionperformance phase diagram of AgCu(Se,S,Te)pseudoternary solid solutions;(b)temperature dependence of ZT value of AgCuSe-based FTE materials;(c)flexibility of AgCuSe0.22S0.08Te0.7;(d)FTE device fabricated by AgCuSe0.22S0.08 73 |

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

(胡惠平, 夏凯阳, 朱铁军, 赵新兵. 稀有金属, 2020, 45(5): 513.).

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

| [74] |

|

| [75] |

|

| [76] |

|

| [77] |

|

| [78] |

|

| [79] |

|

| [80] |

|

| [81] |

|

| [82] |

|

| [83] |

|

| [84] |

|

| [85] |

|

| [86] |

|

| [87] |

|

| [88] |

|

| [89] |

|

/

| 〈 |

|

〉 |