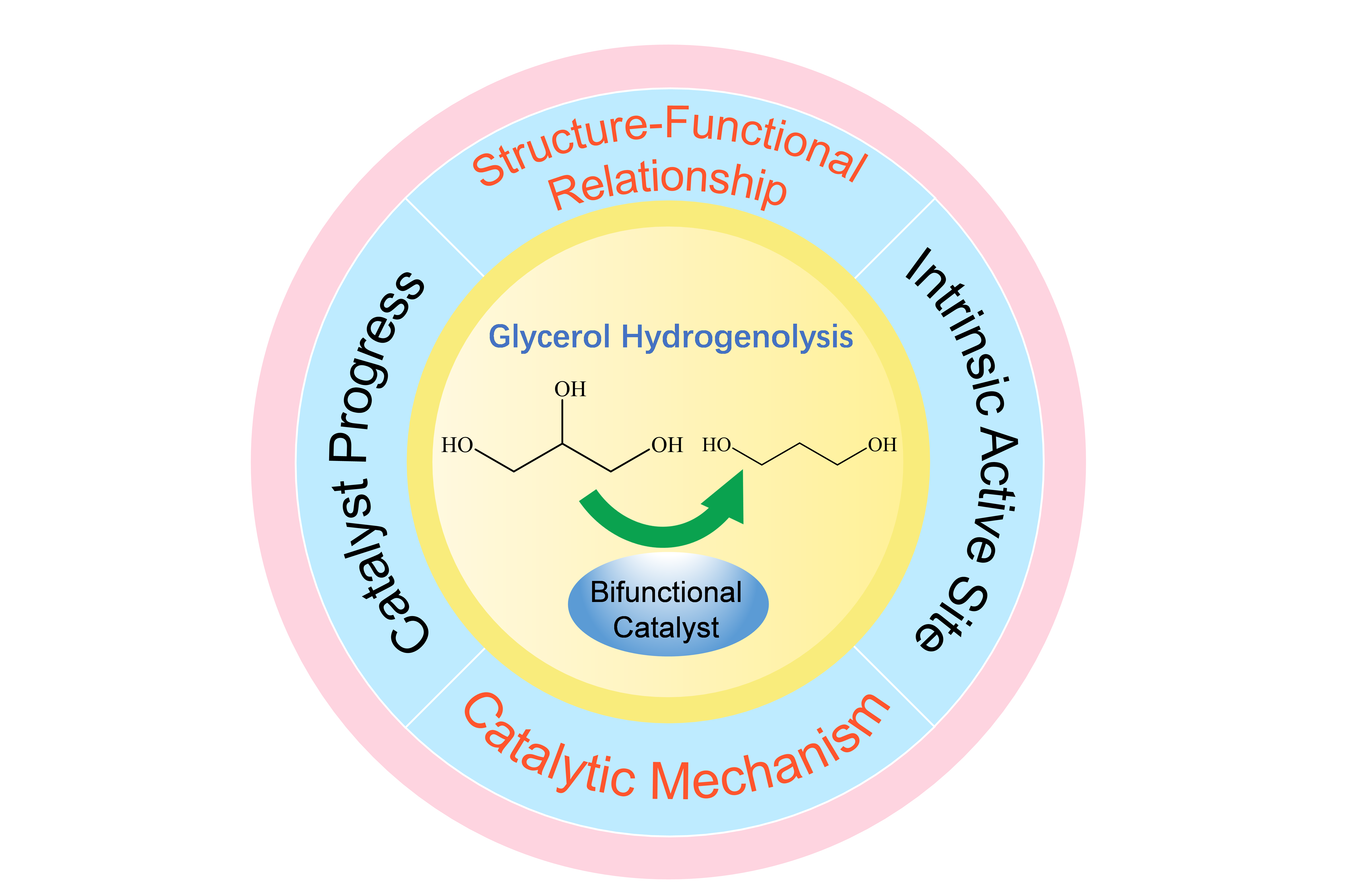

Directed Preparation of 1,3-Propanediol From Glycerol Via Chemoselective Hydrogenolysis Over Bimetallic Catalyst: Active Sites, Structure-Functional Relationship and Mechanism

Received date: 2023-06-19

Revised date: 2023-11-11

Online published: 2024-01-08

Supported by

National Key R&D Program of China(2023YFA1506603)

National Natural Science Foundation of China(22002118)

National Natural Science Foundation of China(22208262)

Postdoctoral Research Foundation of China(2020M683528)

Postdoctoral Research Foundation of China(2020TQ0245)

Natural Science Foundation of Shaanxi Provincial Department of Education(21JP086)

Talent Fund of Association for Science and Technology in Shaanxi, China(20230625)

1,3-propanediol is one of the most important monomers in the polyester industry. Catalytic conversion of glycerol to 1,3-propanediol has important application value. In this article, we reviewed the research progress of bimetallic catalysts for the hydrogenolysis of glycerol to 1,3-propanediol, especially emphasizing Pt-W catalytic systems with high catalytic efficiency and great industrial application prospects. By reviewing the interaction between W species, with different microstructures and chemical environments, and Pt metal, as well as the structure-performance relationship between Pt-W dual sites and glycerol hydrogenolysis, the influence of in-situ generated Brønsted acid active species on catalytic activity, selectivity, and stability was summarized, the source of in-situ generated Brønsted acid and catalytic mechanism was discussed, and finally, the development of bimetallic catalysts for selective hydrogenolysis of glycerol to 1,3-propanediol was prospected.

Contents

1 Introduction

2 Catalyst system for selective hydrogenation of glycerol to 1,3-Propandiol

2.1 Tungsten-based catalyst

2.2 Rhenium-based catalyst

2.3 Other catalysts

3 Mechanism of selective hydrogenolysis of glycerol to 1, 3-propanediol

3.1 Dehydration-hydrogenation mechanism

3.2 Etherification-hydrogenation mechanism

3.3 Dehydrogenation-dehydration-hydrogenation mechanism

3.4 Chelation-hydrogenation mechanism

3.5 Mechanism of direct hydrogenolysis

4 Conclusion and outlook

Man Yang , Yuxiang Jiao , Yujing Ren . Directed Preparation of 1,3-Propanediol From Glycerol Via Chemoselective Hydrogenolysis Over Bimetallic Catalyst: Active Sites, Structure-Functional Relationship and Mechanism[J]. Progress in Chemistry, 2024 , 36(2) : 256 -270 . DOI: 10.7536/PC230615

表1 钨基催化剂在甘油选择氢解制1,3-丙二醇反应中的应用Table 1 Application of tungsten based catalyst in selective hydrogenolysis of glycerol to 1, 3-propanediol |

| Catalyst | T(K) | H2 pressure (MPa) | Solvent | Glycerol phase | Conversion(%) | 1,3-Propanediol selectivity(%) | ref |

|---|---|---|---|---|---|---|---|

| Rh(CO)2(acac)+H2WO4 | 473 | 32 (syngas) | 1-methyl-2-pyrrolidinone | liquid | 48.0 | 44.0 | 8 |

| Rh/C+H2WO4 | 453 | 8.0 | Sulfone | liquid | 32.0 | 12.0 | 9 |

| Pt/Al2O3 | 473 | 4.0 | H2O | liquid | 49.0 | 28.0 | 10 |

| Cu-HSiW/SiO2 | 483 | 0.54 | - | vapor | 83.4 | 32.1 | 11 |

| Pt-HSiW/SiO2 | 473 | 6 | H2O | liquid | 81.2 | 31.4 | 12 |

| Pt-LiSiW/ZrO2 | 453 | 5 | H2O | liquid | 43.5 | 53.6 | 13 |

| Pt-HPW/ZrO2 | 403 | 4 | H2O | liquid | 53.4 | 44.5 | 14 |

| Pt/WO3/ZrO2 | 443 | 8 | 1,3-dimethyl-2-imidazolidinone | liquid | 85.8 | 28.2 | 15 |

| Pt/WO3/ZrO2 | 443 | 8 | 1,3-dimethyl-2-imidazolidinone- H2O | liquid | 31.6 | 34.9 | 16 |

| Pt/W/SiZr | 453 | 5 | H2O | liquid | 90.1 | 44.5 | 17 |

| Pt/WO3/ZrO2 | 413 | 8 | H2O | liquid | 78.3 | 64.8 | 18 |

| Pt/WO3/ZrO2 | 403 | 4 | H2O | liquid | 70.2 | 45.6 | 19 |

| Pt/WOx/ZrO2 | 453 | 5 | - | vapor | 54.3 | 52 | 20 |

| Pt/WOx/ZrO2 | 453 | 8 | H2O | liquid | 56.2 | 50.6 | 21 |

| Pt-W/TiO2 | 513 | 3 | H2O | liquid | 24.9 | 51.5 | 22 |

| Pt/TiO2+WOx/TiO2 | 423 | 4 | H2O | liquid | 97.8 | 46.9 | 23 |

| Pt/W-S/Ti | 393 | 4 | H2O | liquid | 100 | 36 | 24 |

| Pt/W-S/Ti | 393 | 4 | H2O | liquid | 90 | 43 | 24 |

| Pt/W/Ti | 413 | 6 | H2O | liquid | 70.7 | 58 | 25 |

| Pt/WO3/TiO2/SiO2 | 453 | 5.5 | H2O | liquid | 15.3 | 50.5 | 26 |

| Pt/WO3/SBA-15 | 483 | 0.1 | - | vapor | 86 | 42 | 28 |

| Pt/W/SBA-15 | 463 | 8 | H2O | liquid | 75.9 | 32.1 | 29 |

| Pt-WOx/SAPO-34 | 483 | 6 | H2O | liquid | 44.3 | 19.2 | 30 |

| Pt-W/Al2O3 | 433 | 3 | H2O | liquid | 23.0 | 67.0 | 33 |

| Pt/WOx/AlOOH | 453 | 5 | H2O | liquid | 100 | 66 | 34 |

| Pt/WAlSi | 433 | 6 | H2O | liquid | 48 | 56 | 34 |

| Pt/WOx/Al2O3 | 433 | 5 | H2O | liquid | 64.2 | 66.1 | 37 |

| Pt/WOx/Al2O3 | 473 | 4.5 | H2O | liquid | 53.1 | 51.9 | 38 |

| Pt/WOx/Al2O3 | 453 | 5 | H2O | liquid | 80.4 | 35.3 | 39 |

| WPt/SiO2 | 453 | 8 | H2O | liquid | 64.2 | 57.2 | 40 |

| Pt/W-SBA-15 | 423 | 4 | H2O | liquid | 86.8 | 70.8 | 41 |

| Pt/W-MCFs | 423 | 4 | H2O | liquid | 97 | 65 | 42 |

| Pt/WO4/Al2O3 | 453 | 5 | H2O | liquid | 51.7 | 45.7 | 43 |

| Pt/TiW | 453 | 5.5 | H2O | liquid | 24.2 | 33.5 | 44 |

| Pt/m-WO3 | 453 | 5.5 | H2O | liquid | 18.0 | 39.3 | 45 |

| Pt/WOx | 413 | 1 | H2O | liquid | 37.4 | 35.1 | 46 |

| AuPt/WOx | 413 | 1 | H2O | liquid | 81.4 | 51.6 | 47 |

| Pt/Nb-WOx | 433 | 5 | H2O | liquid | 40.3 | 27.5 | 48 |

| Pt/Au/WO3 | 428 | 5 | H2O | liquid | 30.7 | 54.3 | 49 |

| Pt/Al-WOx | 433 | 3 | H2O | liquid | 79.0 | 40.6 | 52 |

a Vapor: fixed-bed reactor, Liquid: reaction kettle reactor |

表2 Pt-W和Ir-Re体系催化甘油选择氢解反应对比Table 2 The comparison between Pt-W and Ir-Re catalysts in selective hydrogenolysis of glycerol |

| Ir-Re | Pt-W | |

|---|---|---|

| structure | metal Ir load 3D ReOx | 2D WOx load metal Pt |

| Ir/Re or Pt/W atomic ratio | ~1 | 1/4 ~ 1/2 |

| reaction temperature | 120 ℃ | 160~180 ℃ |

| H2 pressure | 8 MPa | 3~5 MPa |

| additive | H+ | none |

| [1] |

|

| [2] |

(樊利民, 王菊华, 裴文. 浙江化工, 2009, 40 (6): 22.)

|

| [3] |

|

| [4] |

(李烁, 李靖. 精细与专用化学品, 2022, 30(3): 12.)

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

陈长林, 宋敏洁, 秦丽珍. 南京工业大学学报(自然科学版), 2011, 33(1): 1.)

|

| [15] |

|

| [16] |

(龚磊峰, 吕元, 丁云杰, 林荣和, 李经伟, 董文达, 王涛, 陈维苗. 催化学报, 2009, 30(12): 1189.)

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

| [74] |

|

| [75] |

|

| [76] |

|

| [77] |

|

| [78] |

|

| [79] |

|

| [80] |

|

| [81] |

|

| [82] |

|

| [83] |

|

| [84] |

|

/

| 〈 |

|

〉 |