Biomaterials Based on Lignocellulose

Received date: 2023-09-07

Revised date: 2024-01-07

Online published: 2024-04-16

Supported by

Fundamental Research Funds for the Central Universities(2242022R10058)

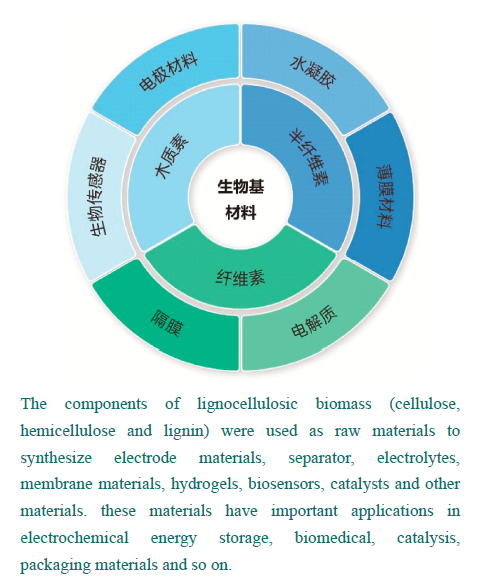

with the continuous depletion of fossil energy and the continuous destruction of the ecological environment,developing environmentally friendly renewable electrochemical energy storage devices and biomedical materials is particularly urgent.as an important renewable resource,lignocellulosic biomass has the advantages of low cost,easy accessibility,environmental friendliness,and rich pore structure,and it has a wide range of application prospects as a renewable,biodegradable,and biocompatible substrate for excellent modified materials.the treatment of biomass materials has been from the traditional methods(including combustion,feed,fertilizer and matrix processing),and gradually towards energy,ecology,material modification,and the preparation of new bio-based functional and smart material products,such as:high-performance energy storage devices and biomedical equipment.in short,the development of new matrix and functional materials With biomass as the main raw material is the development trend.In this study,the latest research progress In preparing biomass-derived materials for high-performance energy storage devices and biomedical fields is summarized and overlooked,and the problems and challenges are also pointed out。

1 Introduction

2 Application of bio-based materials in electro chemical energy storage

2.1 Super capacitor

2.2 Lithium battery

3 Applications in biomedical

3.1 Cellulose-based materials

3.2 Hemicellulose-based materials

3.3 Lignin-based materials

4 Conclusion and outlook

Key words: lignin; cellulose; hemicelluloses; bio-based materials; synthetic materials

Bin Xu , Jianguo Liu , Xinghua Zhang , Lungang Chen , Qi Zhang , Longlong Ma . Biomaterials Based on Lignocellulose[J]. Progress in Chemistry, 2024 , 36(5) : 709 -723 . DOI: 10.7536/PC230903

图5 (a) 碳化CNF和碳纳米管组装的柔性MoS2基纸电极[34]; (b) 柔性MXene@CNF薄膜锂离子电池正极[37];(c) 导电纤维素纳米纤维实现的Li-LFP电池[38]Fig. 5 (a) Flexible MoS2-based paper-electrode assembled with carbonized CNF and CNTs[34]; (b) lithium-ion battery cathodes of flexible MXene@CNF film[37]; (c) Li-LFP batteries enabled by conductive cellulose nanofiber[38] |

图7 (a) BC支撑型P(MVE-MA)制造工艺的示意图;(b) BC支撑型P(MVE-MA)膜的侧视扫描电子显微镜图像;(c) BC支撑型P(MVE-MA)膜、无BC支撑型P(MVE-MA)膜和聚丙烯隔膜的应力-应变曲线[44]Fig. 7 (a) Schematic representation of the BC supported P(MVE-MA) fabrication process; (b) side-view SEM image of the BC supported P(MVE-MA) membrane; (c) stress-strain curves of the BC supported P(MVE-MA) membrane, the P(MVE-MA) membrane without BC, and polypropylene separator[44] |

图9 (a) GPE膜的照相图像;(b) 木质素膜对液体电解质的吸收率依赖于时间;(c) 木质素膜以1 mm/min的速率吸收前后的应力-应变曲线[51]Fig. 9 (a) The photographic images of GPE membrane; (b) the liquid electrolyte uptake of lignin membrane depends on time;(c) the stress-stain curves of lignin membrane after and before absorption at the rate of 1 mm/min[51] |

| [1] |

( 朱清时, 郭庆祥, 阎立峰. 生物质洁净能源. 化学工业出版社, 2002.)

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

Kuek Lawrence C S,

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

| [74] |

|

| [75] |

|

| [76] |

|

| [77] |

|

| [78] |

|

| [79] |

|

| [80] |

|

/

| 〈 |

|

〉 |