Application of Copper-Based Catalysts for the Selective Catalytic Combustion of Ammonia

Received date: 2023-08-17

Revised date: 2023-12-14

Online published: 2024-03-15

Supported by

Youth Innovation Promotion Association, Chinese Academy of Sciences(2021413)

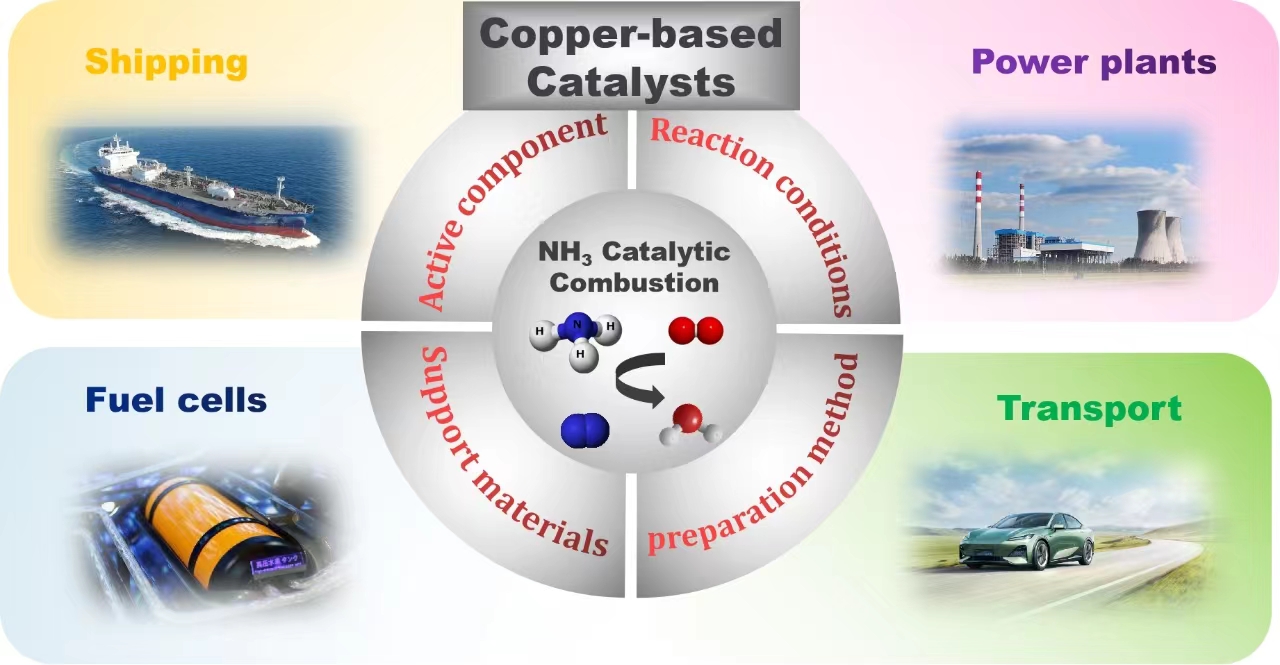

Ammonia is a promising new energy carrier that has the potential to replace traditional fossil fuels due to its high calorific value,CO2emission-free and renewable properties,and low storage and transportation costs.However,ammonia combustion faces several challenges,such as high NOxemission,slow combustion rate,and ignition difficulties.To address these challenges,selective catalytic combustion is an efficient and promising way that can decrease combustion temperature,enhance combustion stability,improve fuel conversion rate and reduce NOxemission while requiring less auxiliary fuel and consuming less energy.Copper-based catalysts are cost-effective and they are demonstrated to exhibit excellent performance in ammonia catalytic combustion with high N2selectivity.In this review,the reaction experimental setup and primary mechanisms,namely NH-HNO,N2H4and i-SCR pathways,are presented first;then,the recent research progress on copper-based supported catalysts for ammonia combustion,including the effect of preparation methods,types of support materials,metal-support interactions,and Cu-based single or multiple active components on catalytic performance are reviewed in detail.Finally,the review is concluded by summarizing the research achievements,current drawbacks and proposing the future developments 。

1 Introduction

2 Catalytic NH3combustion experimental setup and mechanisms

2.1 Experimental setup and performance indicators

2.2 Mechanism and research techniques

3 Copper-based catalysts for NH3combustion

3.1 The effect of preparation methods on performance

3.2 The effect of support on performance

3.3 The effect of active component on performance

4 Conclusion and outlook

Qian Zhang , Runze Tao , Yu Huang , Houzhang Tan , Baochong Cui . Application of Copper-Based Catalysts for the Selective Catalytic Combustion of Ammonia[J]. Progress in Chemistry, 2024 , 36(5) : 783 -797 . DOI: 10.7536/PC230816

表1 Comparison of Three New Energy Carriers: Ammonia, Hydrogen and Natural Gas[7⇓⇓⇓~11]Table 1 Comparison of three new energy carriers-ammonia,hydrogen and natural gas[7⇓⇓⇓-11] |

| Fuel | Boiling point (1 atm, ℃) | Liquefaction pressure (25 ℃, MPa) | Lower calorific value (MJ/m3) | Minimum ignition energy (MJ) | Flame speed (cm/s) | Production cost (RMB Yuan/t) | Transportation cost (RMB Yuan/t, 100 km) |

|---|---|---|---|---|---|---|---|

| NH3 | -33.34 | 1.03 | 22.5 | 11.3 | 10 | 4900 | 150 |

| H2 | -252.77 | 70 | 142 | 3.75 | 280~320 | 27000~29500 | 8660 |

| Natural gas | -161 | 0.3 | 55 | 0.31 | 38 | 4000 | 100 |

图5 (a) CuOx/Al2O3-H和CuO/Al2O3-A两种催化剂的H2-TPR曲线;(b) 不同催化剂表面NH3吸附随时间变化的原位漫反射红外光谱;(c, d) CuOx/Al2O3-H和CuO/Al2O3-A催化剂表面NH3催化氧化性能的NH3转化率和N2选择性,反应条件:气体组成为500 ppm NH3, 5 vol% O2和N2平衡气,空速GHSV为60 000 h-1;(e) CuOx/Al2O3-H催化剂表面“快速i-SCR”反应机制[34]Fig. 5 (a) H2-TPR profiles of (a) CuOx/Al2O3-H and (b) CuO/Al2O3-A catalysts. (b) In situ DRIFTs recorded during NH3 adsorption as a function of time upon different samples. (c) NH3-SCO light-off curves and (d) plots of N2 selectivity as a function of NH3 conversion of CuOx/Al2O3-H and CuO/Al2O3-A catalysts. Reaction conditions: 500 ppm NH3, 5 vol % O2, N2 as the balance, and GHSV of 60 000 h-1. (e) Reaction pathways in the proposed ′′fast i-SCR′′ mechanism over the CuOx/Al2O3-H catalyst [34]. Copyright 2022, American Chemical Society |

表2 Effect of Different Kinds of Metal Oxide Supports on the Performance of Cu-based Catalysts[20]Table 2 Effect of different types of metal oxide supports on the performance of copper based catalysts[20]。 Copyright 2018,Elsevier |

| Supports | T10/℃ | T90/℃ | Selectivity(T90) | SBET/m2·g−1 | DCu/% | Cu Particle size/nm | ||

|---|---|---|---|---|---|---|---|---|

| N2 | N2O | NO | ||||||

| MgO | 360 | 487 | 83 | 1 | 16 | 33 | 29 | 3.6 |

| Al2O3 | 303 | 476 | 92 | 6 | 2 | 149 | 43 | 2.4 |

| 10A2B | 307 | 474 | 97 | 2 | 1 | 77 | 27 | 3.9 |

| AlPO4 | 351 | 501 | 95 | 3 | 2 | 64 | 12 | 8.6 |

| SiO2 | 334 | 490 | 97 | 1 | 2 | 177 | 11 | 9.4 |

| TiO2 | 340 | 481 | 73 | 4 | 23 | 9 | 19 | 5.3 |

| ZrO2 | 306 | 438 | 84 | 2 | 14 | 11 | 25 | 4.1 |

| La2O3 | 290 | 440 | 57 | 6 | 37 | 13 | 30 | 3.4 |

| CeO2 | 301 | 476 | 88 | 1 | 11 | 137 | 42 | 2.5 |

表3 Performance of Single Component Supported Cu-based Catalysts for Ammonia OxidationTable 3 Ammonia oxidation performance of single component copper-based catalysts |

| Catalyst types | Preparation method | Reaction conditions (Gas composition and space velocity) | Reaction temperature (℃) | Performance | Ref | |

|---|---|---|---|---|---|---|

| NH3 Conversion (%) | N2 Selectivity (%) | |||||

| CuOx/Al2O3-600 CuOx/Al2O3-900 | Wet impregnation | NH3 (0.6%~1.0%)+O2 (1.5%~3.75%) + He W/F = 5.0×10−4 g·min·cm−3 | 476 450 | 90 90 | 92 91 | 17 |

| CuOx/10A2B | Wet impregnation | NH3 (0.6%~1.0%)+O2 (1.5%~3.75%) + He W/F = 5.0×10−4 g·min·cm−3 | 474 | 90 | 97 | 19 |

| CuOx/3A2S CuOx/Al2O3 CuOx/SiO2 | Wet impregnation | NH3 (0.6%~1.0%)+O2 (1.5%~3.75%) + He W/F = 5.0×10−4 g·min·cm−3 | 484 476 490 | 90 90 90 | 97 92 97 | 20 |

| 10 wt%Cu/TiO2 | Wet impregnation | 0.04%NH3+10%O2 + He Space velocity: 50 000 h−1 | 250 | 95 | 95 | 30 |

| CuO-Fe2O3 | Sol-gel | 0.08%NH3+0.01%SO2+10%H2O+5%O2+Ar Space velocity: 60 000 h−1 | 225 | 100 | - | 60 |

| 5 wt%Cu/Al2O3 10 wt%Cu/Al2O3 15 wt%Cu/Al2O3 | Wet impregnation | 1.14%NH3+8.21%O2+ He | 350 350 350 | 75 100 100 | 96 90 94 | 28 |

| 3.7 wt%Cu/NaY 8.4 wt%Cu/NaY | Wet impregnation | 1.14%NH3+8.21%O2+ He | 350 350 | 100 100 | 97 98 | 28 |

| 1.2 wt%Cu/beta 3.0 wt%Cu/beta 6.6 wt%Cu/beta 4.3 wt%CuO/Al2O3 | Wet impregnation | 0.54%NH3+8%O2+ He W/F = 0.015 g·s·mL−1 | 400 400 400 400 | 90 100 100 100 | 98 98 98 51 | 29 |

| 10 wt%Cu(S)/γ-Al2O3 10 wt%Cu(AC)/γ-Al2O3 10 wt%Cu(N)/γ-Al2O3 | Wet impregnation | 0.1%NH3+10%O2+He Space velocity: 50 000 h−1 | 350 350 350 | 95 85 100 | 99 93 100 | 52 |

| 1 wt%Cu/Al2O3 5 wt%Cu/Al2O3 10 wt%Cu/Al2O3 15 wt%Cu/Al2O3 | Wet impregnation | 0.5%NH3+2.5%O2+ 97%Ar WHSV=24 000 mL/h/g | 379 450 425 425 | 50 100 100 100 | 96 81 85 83 | 49 |

| 10 wt%Cu/Al2O3 | Wet impregnation | 1%NH3+10%O2+ 89%He | 350 | 92 | 96 | 77 |

| 10 wt%Cu/Al2O3 | Wet impregnation | 1.14%NH3+8.21%O2+ 89%He WHSV=22410 NmL/h/g | 350 | 100 | 90 | 78 |

| 1 wt%Cu/TiO2 | Wet impregnation | 0.5%NH3+2.5%O2+ 97%He | 425 | 100 | 54 | 33 |

| 1 wt%Cu/Al2O3 | Wet impregnation | 0.5%NH3+2.5%O2+ 97%He | 500 | 100 | 96 | 33 |

表4 Ammoxidation performance of multi-component supported Cu-based catalystTable 4 Ammonia oxidation performance of multi-component supported copper-based catalysts |

| Catalyst types | Preparation method | Reaction conditions (Gas composition and space velocity) | Reaction temperature (℃) | Performance | Ref | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NH3 Conversion (%) | N2 Selectivity (%) | ||||||||||||

| 6 wt%CuOx/10 wt%Ag/Al2O3 10 wt%Ag/6 wt%CuOx/Al2O3 | Wet impregnation | NH3 (0.6%~1.0%) + O2 (1.5%~3.75%) + He; W/F = 5.0 × 10-4 g·min·cm-3 | 370 365 | 90 90 | 98 99 | 17 | |||||||

| 1 wt%Pt/20 wt%CuO/Al2O3 4 wt%Pt/20 wt%CuO/Al2O3 | Wet impregnation | 0.07%NH3+8%O2+ N2 Space velocity: 3600 mL/(min·gcat) | 235 235 | 100 100 | 79 84 | 62 | |||||||

| 1 wt%Pt/20 wt%CuO/Al2O3 1 wt%Pt/20 wt%CuO/Al2O3 | Wet impregnation | 0.7%NH3 + 8%O2 + N2 Space velocity: 3600 mL/(min·gcat) | 235 235 | 100 100 | 98 98 | 79 | |||||||

| 1.5 wt%Ru/1.5 wt%Cu/C | Reduction | 0.1% NH3 | 180 | 95 | 92 | 80 | |||||||

| 1 wt% Ag/1 wt%Cu/Al2O3 1 wt% Ag/10 wt%Cu/Al2O3 1.5 wt% Ag/10 wt%Cu/Al2O3 5 wt% Ag/5 wt%Cu/Al2O3 | Wet impregnation | 0.5%NH3 + 2.5%O2 + 97%Ar WHSV = 24000 mL·h-1·g-1 | 475 375 375 275 | 100 100 100 100 | 87 92 94 79 | 49 | |||||||

| 5 wt%Cu/5 wt%Ag/Al2O3 | Wet impregnation | 1%NH3 + 10%O2 + 89%He WHSV=30000 mL·h-1·g-1 | 320 | 100 | 95 | 81 | |||||||

| 5 wt%Cu/5 wt%Ag/Al2O3 10 wt%Cu/10 wt%Ag/Al2O3 | Wet impregnation | 1%NH3 + 10%O2 + 89%He | 320 280 | 100 100 | 96 78 | 77 | |||||||

| 1 wt%Cu/0.5 wt%Pt/TiO2 | Equal volume impregnation | 0.5%NH3 + 2.5%O2 + 97%He | 325 | 100 | 90 | 33 | |||||||

图7 (a) 核-壳型Pt/Al2O3@Cu/ZSM-5催化剂多步合成策略;(b) CS, P(0.05)-A和P(0.15)-A三种催化剂表面NH3催化氧化性能,其中(a,b)分别为NH3转化率和N2产率;(c) P(0.05)-A, P(0.05)-AS, P(0.05)-AS-S1和CS 4种催化剂表面NH3催化氧化性能,(a, b)分别为NH3转化率和N2产率,测试条件:催化剂0.18 g,反应气体为500 ppm NH3,5% O2,其余为平衡气体Ar,流速1000 sccm[83]Fig. 7 (a) Multiple synthesis steps involved in the preparation of core−shell (CS) catalysts with a Cu/ZSM-5 shell (SCR catalyst) and a Pt/Al2O3 core (PGM catalyst). (b) Steady-state NH3 oxidation over three catalysts: CS, P(0.05)-A, and P(0.15)-A with 0.05, 0.15, and 0.05 wt% Pt, respectively. Comparisons are made for the (a) NH3 conversion and (b) N2 yield. For each experiment, 0.18 g of the catalyst was used in the fixed bed. Feed conditions: 500 ppm NH3, 5% O2, balance Ar, 1000 sccm. (c) Steady-state NH3 oxidation over four catalysts: P(0.05)-A, P(0.05)-AS, P(0.05)-AS-S1, and CS. Each sample contains 0.05 wt% Pt and represents one of the four different stages of catalyst synthesis (Figure 7a). Reaction data are plotted for (a) NH3 conversion and (b) N2 yield. Feed conditions: 500 ppm NH3, 5% O2, balance Ar, 1000 sccm, and 0.18 g of the catalyst[83]. Copyright 2020, American Chemical Society |

| [1] |

( 彭觅, 吕斌, 张纯, 黄斌. 城市发展研究, 2010, 17(7): 6.)

|

| [2] |

National Bureau of Statistics of China. China Statistical Yearbook. Beijing: China Statistics Press, 2021.

( 中华人民共和国国家统计局. 中国统计年鉴. 北京: 中国统计出版社, 2021.)

|

| [3] |

( 严刚, 郑逸璇, 王雪松, 李冰, 何捷, 邵朱强, 李永亮, 吴立新, 丁焰, 徐伟, 李新, 蔡博峰, 陈潇君, 宋晓晖, 王倩, 雷宇, 王金南. 环境科学研究, 2022, 35(2): 309.)

|

| [4] |

( 谢和平, 任世华, 谢亚辰, 焦小淼. 煤炭学报, 2021, 46(7): 2197.)

|

| [5] |

( 崔夏瑜. 能源与节能, 2022, (5): 33.)

|

| [6] |

|

| [7] |

|

| [8] |

( 谭厚章, 周上坤, 杨文俊, 崔保崇, 邓双辉, 王金华, 王学斌. 中国电机工程学报, 2023, 1: 181.)

|

| [9] |

( 夏鑫, 蔺建民, 李妍, 陶志平. 化工进展, 2022, 41(5): 2332.)

|

| [10] |

( 李海洋. 化学工程, 2021, 49(11): 73.)

|

| [11] |

( 赵志强. 武汉理工大学博士学位论文, 2013.)

|

| [12] |

( 王月姑, 吴崇君, 郑淞生, 陈锦, 何嵩, 王兆林. 可再生能源, 2019, 37(7): 949.)

|

| [13] |

( 李育磊, 刘玮, 董斌琦, 夏定国. 储能科学与技术, 2022, 11(9): 2891.)

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

( 赵雪纯. 山东化工, 2022, 51(10): 72.)

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

( 张黎明, 秦永宁, 沈美庆, 齐晓周, 宋健. 燃烧科学与技术, 2000, 1: 70.)

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

| [74] |

|

| [75] |

|

| [76] |

|

| [77] |

( 吴成强, 张长斌, 张昱, 贺泓, 杨敏. 中国环境科学, 2004, 24(6): 670.)

|

| [78] |

|

| [79] |

|

| [80] |

|

| [81] |

|

| [82] |

|

| [83] |

|

| [84] |

|

| [85] |

|

/

| 〈 |

|

〉 |