Sulfate Radicals: A New Tool for Enhancing Sludge Dewatering

Received date: 2023-07-14

Revised date: 2024-01-28

Online published: 2024-04-16

Supported by

Open Fund of Key Laboratory of Green Technology in Ecological Industry of Fujian Province(WYKF-EIGT2021-3)

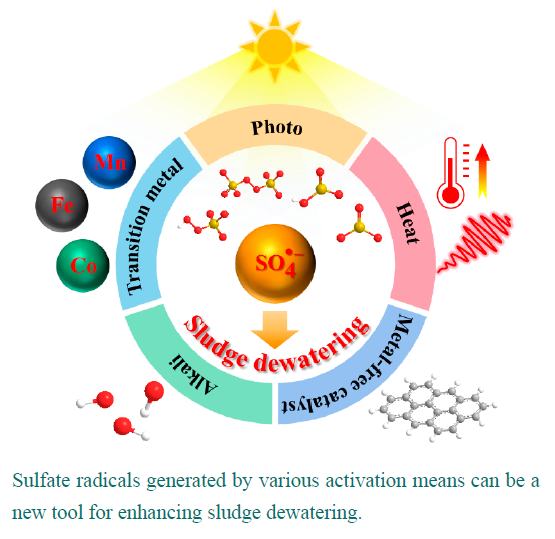

sludge is an inevitable by-product of the wastewater treatment process and due to its high water content,large volume,and inclusion of a large amount of toxic and hazardous substances,needs to be minimized and harmlessly treated.However,sludge possesses extracellular polymeric substances(EPS)formed by ionization of negatively charged functional groups,which maintain a stable hydrated colloidal structure and prevent the release of water.this is a key factor in the difficulty of sludge dewatering.in the last decade,sulfate radical-Based advanced oxidation processes(SR-AOPs)have received considerable attention due to their high efficiency for EPS disintegration,rapid reaction time and environmental friendliness,and thus sulfate radicals have become a new powerful tool for enhancing sludge dewaterability.in This paper,the development timeline and activation mechanisms of sulfate radicals are reviewed in detail,and the research advances of SR-AOPs for improving sludge dewaterability and removing micropollutants and heavy metals from sludge are systematically evaluated.based on the current scientific problems of SR-AOPs in sludge conditioning,the future research directions of SR-AOPs are proposed from the perspectives of mechanism research,cost-effectiveness,and experimental scale,in order to provide a solid theoretical reference for sludge conditioning in wastewater treatment plants in China。

1 Introduction

2 Timeline of sulfate radicals

3 Mechanism of sulfate radicals activation

3.1 Transition metal activation

3.2 Photo activation

3.3 Heat activation

3.4 Alkali activation

3.5 Metal-free catalyst activation

4 Sludge dewaterability improved by SR-AOPs

4.1 Iron activated methods

4.2 Heat activated methods

4.3 Electrochemically activated methods

4.4 Alkali activated methods

4.5 Other activation methods

5 Removal of micropollutants

6 Removal of heavy metals

7 Sludge dewatering mechanism

8 Conclusion and outlook

Yue Lai , Chao Wang , Jie Zhang , Shungui Zhou , Changgeng Liu , Jie Ye . Sulfate Radicals: A New Tool for Enhancing Sludge Dewatering[J]. Progress in Chemistry, 2024 , 36(5) : 798 -814 . DOI: 10.7536/PC230707

表1 Mechanism of activation of different precursors to produce sulfate radicalTable 1 Activation of different precursors to produce sulfate radical mechanisms |

| Activation method | Precursor | Mechanism | Predominant radical species | Comments | Ref |

|---|---|---|---|---|---|

| Transition metals | PMS | One electron transfer | SO4 | / | 62 |

| PDS | One electron transfer | SO4 | / | 62 | |

| SF | Involves several transient short-lived oxysulfur radicals initiated by direct one-electron transfer from SF to metal ions | $\mathrm{SO}_{4}^{\centerdot -}$/$\cdot \ \mathrm{OH}$ | / | 63 | |

| Photo | PMS | Breaking of O−O bond | $\mathrm{SO}_{4}^{\centerdot -}$/$\cdot \ \mathrm{OH}$ | / | 64 |

| PDS | Breaking of O−O bond | SO4 | / | 65 | |

| SF | Photoelectrons and holes can be produced from photocatalysts, the generated holes can activate sulfite to form oxysulfur radicals | $\mathrm{SO}_{4}^{\centerdot -}$/$\cdot \ \mathrm{OH}$/$\mathrm{O}_{2}^{\centerdot -}$ | / | 15 | |

| Heat | PMS | Breaking of O−O bond | $\mathrm{SO}_{4}^{\centerdot -}$/$\cdot \ \mathrm{OH}$ | The bond dissociation energy is higher, so a higher temperature is required to cleave O−O bond | 66 |

| PDS | Breaking of O−O bond | $\mathrm{SO}_{4}^{\centerdot -}$/$\cdot \ \mathrm{OH}$ | The bond dissociation energy is lower, and increasing the temperature can effectively cleave O−O bond | 67 | |

| SF | SF autoxidation generates oxygen-sulfur radicals | $\mathrm{SO}_{4}^{\centerdot -}$/$\cdot \ \mathrm{OH}$ | / | 68 | |

| Alkali | PMS | Alkali-catalyzed hydrolysis of PMS to hydrogen peroxide | O2 | / | 69 |

| PDS | Alkali-catalyzed hydrolysis of PDS to hydroperoxides triggers free radical formation | $\mathrm{SO}_{4}^{\centerdot -}$/$\cdot \ \mathrm{OH}$/$\mathrm{O}_{2}^{\centerdot -}$ | pH > 11 | 70 | |

| SF | / | / | / | / | |

| Metal-free catalyst | PMS | One electron transfer | SO4 | Graphene exhibits better catalytic properties than several other carbon isomers, including: activated carbon, graphite, graphene oxide, and carbon nanotubes | 38 |

| PDS | Peroxide bond of PDS is weakened at the defective edge of the carbon catalyst and oxygen groups (of which the carbonyl group is the most active) | OH | Reduced mesoporous carbon, carbon nanotubes, and graphene oxide, displayed great catalytic properties, in contrary to nanodiamonds, fullerenes and graphitic carbon nitride | 39 | |

| SF | Bonding to carbon catalyst ketone groups to form complexes with internal electron transfer leading to the formation of oxygen-sulphur radicals | SO4 | / | 71 |

表2 Effect of different iron activators on improvement of sludge dewaterabilityTable 2 Effect of different iron activator on the improvement of sludge dewaterability |

| Catalyst | Chemical | Assisted activation method | Solid content | Dosage | Sludge type | CST(s) | CST reduction(%) | Ref |

|---|---|---|---|---|---|---|---|---|

| Fe2+ | PMS | / | TSS = 12.3 g/L | Fe2+ = 0.81 mmol/g VSS PMS = 0.9 mmol/g VSS | WAS | 201.8 | 90 | 87 |

| / | TSS = 20.4 g/L | Fe2+ = 0.81 mmol/g VSS PMS = 0.9 mmol/g VSS | WAS | 49.1 | 45.67 | 86 | ||

| Chelator | TS = 25.6 g/L | Fe2+ = 0.6 mmol/g VS PMS = 0.9 mmol/g VS Chelator = 0.3 mmol/g VS | ADS | 130.8 | 88.3 | 107 | ||

| Chelator | TSS = 51.62 g/L | Fe2+ = 1.2 mmol/g VSS PMS = 1.0 mmol/g VSS Chelator = 0.4 mmol/g VSS | ADS | 599.9 | 60 | 106 | ||

| PDS | / | TSS = 11.9 g/L | Fe2+ = 1.5 mmol/g VSS PDS = 1.2 mmol/g VSS | WAS | 502.4 | 86.4 | 97 | |

| / | TS = 26.2 g/L | Fe2+ = 2.0 mmol/g VS PDS = 1.6 mmol/g VS | WAS | 681.0 | 88.0 | 96 | ||

| / | TSS = 20.7 g/L | Fe2+ = 1.5 mmol/g VSS PDS = 1.2 mmol/g VSS | WAS | 573.4 | 94.2 | 94 | ||

| Chelator | TS = 20.14 g/L | Fe2+ = 0.6 mmol/g TS PDS = 0.4 mmol/g TS Chelator = 0.15 mmol/g TS | WAS | 836.6 | 96.4 | 109 | ||

| Chelator | TS = 19.9 g/L | Fe2+ = 0.3 mmol/g TS PDS = 0.6 mmol/g TS Chelator = 0.15 mmol/g TS | WAS | 720.4 | 61.5 | 83 | ||

| Skeleton | TSS = 35 g/L | Fe2+ = 23.5 mg/g DS PDS = 100 mg/g DS Skeleton = 300 mg/g DS | WAS | 182 | 84.6 | 111 | ||

| SF | / | VSS/TSS = 51.88% | Fe2+ = 1.79 mmol/L TSS SF = 1.43 mmol/L TSS | WAS | 139.7 | 68.9 | 45 | |

| ZVI | PMS | / | TSS = 23.4 g/L | ZVI = 0.25 g/g TSS PMS = 0.1 g/g TSS | WAS | 48.6 | ~50 | 88 |

| PDS | / | TS = 28.5 g/L | ZVI = 2 g/g TS PDS = 0.5 g/g TS | ADS | 174.7 | 90 | 92 | |

| / | TS = 7.9 g/L | ZVI = 15 g/L PDS = 4 g/L | WAS | 20.5 | 50.2 | 84 | ||

| / | TSS = 15.2 g/L | ZVI = 2 g/g TSS PDS = 0.5 g/g TSS | ADS | 144.6 | 42.6 | 89 | ||

| / | TS = 26.1 g/L | ZVI = 0.05 g/g TS PDS = 0.1 g/g TS | ADS | 119.1 | ~80 | 98 | ||

| Chelator | TSS = 56.37 g/L | ZVI = 0.5 mmol/g TSS PDS = 0.5 mmol/g TSS Chelator = 0.05 mmol/g TSS | WAS | 254.9 | 51.7 | 108 | ||

| SF | / | TS = 23.6 g/L | ZVI = 0.9 mmol/g VS SF = 1.2 mmol/g VS | ADS | 120.9 | 81.7 | 55 |

表3 Sludge dewaterability after thermal activated PMS/PDS oxidation conditioningTable 3 Sludge dewatering performance after treatment by thermally activated PMS/PDS oxidation |

| Temperature (℃) | Chemical | Sludge type | Solid content(g/L) | Dosage | Reaction time | CST(s) | CST reduction(%) | Ref |

|---|---|---|---|---|---|---|---|---|

| 120 | PDS | WAS | TSS = 45.21 | ZVI = 100 mg/g TSS PDS = 200 mg/g TSS | 30 min | 190.6 | 72.4 | 122 |

| 80 | PDS | WAS | TSS = 16.03 | PDS = 2.0 mmol/g VSS | 60 min | 88.1 | 76.6 | 121 |

| PMS | PMS = 0.5 mmol/g VSS | 53.9 | ||||||

| 70 | PDS | WAS | TS = 16.5 | PDS = 120 mg/g VS Skeleton = 150 mg/g VS | 10 min | 163.5 | 65.5 | 120 |

| 80 | PDS | WAS | TSS = 41.3 | PDS = 2.0 mmol/g VSS | 60 min | 54.0 | 40.3 | 119 |

| 75 | PMS | WAS | TS = 12.6 | PMS = 150 mg/g VS Skeleton = 100~400 mg/g VS | 40 min | 158.5 | 63.9 | 126 |

| 55 | PDS | ADS | TS = 29.3 | PDS = 3 g/L | 24 h | 230 | 33.2 | 127 |

| PMS | PMS = 3 g/L | 28.0 | ||||||

| 120 | PDS | WAS | TSS = 24.49 | PDS = 120 mg/g TSS | 30 min | 100.7 | 57.6 | 128 |

| 60 | PMS | WAS | TSS = 13.6 | Fe2+ = 0.6 mmol/g VSS PMS = 1.0 mmol/g VSS | 20 min | 206.3 | 92.9 | 124 |

| 60 | PDS | WAS | TSS = 26.4 | Fe2+ = 1.5 mmol/g VSS PDS = 1.2 mmol/g VSS | 20 min | 3006.1 | 96.6 | 123 |

表4 Degradation of trace pollutants in sludge by different SR-AOPsTable 4 Degradation of micropollutant in sludge by different SR-AOPs |

| Item | Process | Chemical | Dosage | Micropollutant | Initial concentration | Removal rate(%) | Ref |

|---|---|---|---|---|---|---|---|

| Aromatic compounds | poly(3-hydroxybutyrate)/PMS Fe2+/S2O82- | PMS PDS | PMS = 3.1 × 10-4 M PHB = 3.3 g/L Fe2+ = 2.0 mmol/g VS PDS = 1.6 mmol/g VS | PAHs | 3099 ± 32 ng/g dw 2692.0 μg/kg | 79 | 149 96 |

| Toluene | 89.8 | ||||||

| Biochar/S2O82- | PDS | PDS = 10 mmol/L Catalyst = 0.5 g/L | Phenol | 200 mg/L | 57.8 | 150 | |

| Phenolic compounds | Biochar/S2O82- | PDS | PDS = 10 mmol/L Catalyst = 0.5 g/L | Phenol | 200 mg/L | 57.8 | 150 |

| Antibiotics | MW(160 ℃)/S2O82- | PDS | PDS = 0.87 g/g TS | Oxytetracycline | 2 mg/g TS | 98.9 | 151 |

| Ciprofloxacin | 98.3 | ||||||

| Modified sludge bio-hydrochar/S2O82- | PDS | PDS = 5 mmol/L Catalyst = 0.2 g/L | Tetracycline | 60 mg/L | 99.72 | 152 | |

| Fe2+/75 ℃/S2O82- | PDS | PDS = 22.7 mM | Oxytetracycline | 100 mg/kg TS | 95 | 125 | |

| Ciprofloxacin | 84 | ||||||

| Triclosan | >99 | ||||||

| Fenton sludge-Cu/PMS | PMS | PMS = 20 mg/L Catalyst = 0.2 g/L | Tetracycline | 10 mg/L | 85.53 | 153 |

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

(杨秦辉. 哈尔滨工业大学硕士论文, 2019).

|

| [12] |

(肖一帆. 南京农业大学硕士论文, 2019).

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

| [74] |

(刘军. 湖南大学硕士论文, 2017).

|

| [75] |

(薛茂. 哈尔滨工业大学硕士论文, 2019).

|

| [76] |

|

| [77] |

|

| [78] |

|

| [79] |

|

| [80] |

|

| [81] |

|

| [82] |

|

| [83] |

|

| [84] |

|

| [85] |

|

| [86] |

|

| [87] |

|

| [88] |

|

| [89] |

|

| [90] |

|

| [91] |

|

| [92] |

|

| [93] |

|

| [94] |

|

| [95] |

|

| [96] |

|

| [97] |

|

| [98] |

|

| [99] |

|

| [100] |

|

| [101] |

|

| [102] |

|

| [103] |

|

| [104] |

|

| [105] |

|

| [106] |

|

| [107] |

|

| [108] |

|

| [109] |

|

| [110] |

|

| [111] |

|

| [112] |

|

| [113] |

|

| [114] |

|

| [115] |

|

| [116] |

|

| [117] |

|

| [118] |

|

| [119] |

|

| [120] |

|

| [121] |

|

| [122] |

|

| [123] |

|

| [124] |

|

| [125] |

|

| [126] |

|

| [127] |

|

| [128] |

|

| [129] |

|

| [130] |

|

| [131] |

|

| [132] |

|

| [133] |

|

| [134] |

|

| [135] |

|

| [136] |

|

| [137] |

|

| [138] |

|

| [139] |

|

| [140] |

|

| [141] |

|

| [142] |

|

| [143] |

|

| [144] |

|

| [145] |

|

| [146] |

|

| [147] |

|

| [148] |

|

| [149] |

|

| [150] |

|

| [151] |

|

| [152] |

|

| [153] |

|

| [154] |

|

| [155] |

|

| [156] |

|

| [157] |

|

| [158] |

|

| [159] |

|

| [160] |

(李娜. 华中科技大学硕士论文, 2019).

|

| [161] |

|

| [162] |

|

| [163] |

|

/

| 〈 |

|

〉 |