Design, Synthesis and Application of Magnetic Nanoparticle Catalytic Materials Based on Multientate Palladium Compounds

Received date: 2023-02-01

Revised date: 2023-03-24

Online published: 2023-05-30

Supported by

The Shanghai Young Teachers Training and Support Program(slg20035)

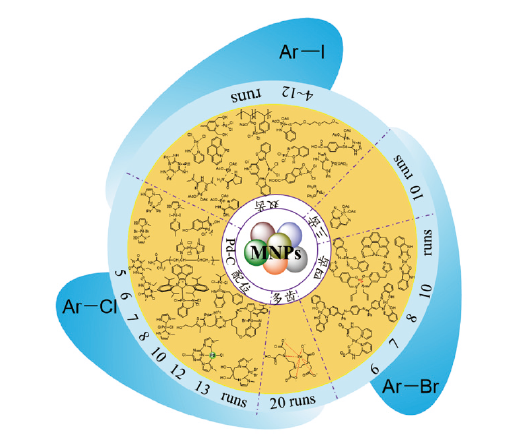

Catalyst loading is one of the effective strategies for green catalysis. Palladium (Pd) catalysts supported by magnetic nanoparticles (MNPs) have been widely studied and used in organic synthesis due to their good dispersibility, high catalytic activity, rapid separation under the action of an external magnetic field, and efficient recovery. The MNPs-supported polydentate Pd compound catalyst (MNPs@L-Pd) shows better catalytic activity and stability than the MNPs-supported Pd nanoparticle catalyst (MNPs@PdNP). This is mainly because the introduction of the modified ligand in MNPs@L-Pd can regulate the electronic effect and steric hindrance of the catalyst metal center to achieve the regulation of its activity, on the other hand, it makes the stable chemical bond between the catalyst metal center and the magnetic material to achieve the regulation of stability. This paper mainly focuses on MNPs@L-Pd, the preparation of MNPs@L-Pd based on different ligands and coordination methods and its application in C-X(Cl, Br, I) activation reaction in the past 10 years are reviewed from the aspects of catalyst stability and activity, and the prospect of these reactions are also presented.

1 Introduction

2 Palladium-catalyzed system based on bidentate coordination mode

2.1 N-Pd-N coordination bond catalytic system

2.2 O-Pd-N coordination bond catalytic system

2.3 P-Pd-P coordination bond catalytic system

2.4 S-Pd-N coordination bond catalytic system

2.5 Se-Pd-N coordination bond catalytic system

3 Palladium-catalyzed system based on tridentate coordination mode

4 Palladium-catalyzed system based on tetradecentate coordination mode

5 Palladium-catalyzed system based on multidentate coordination mode

6 Palladium-catalyzed system based on Pd-C covalent bonds

7 Conclusion and outlook

Yunhua Ma , Han Shao , Tenglong Lin , Qinyue Deng . Design, Synthesis and Application of Magnetic Nanoparticle Catalytic Materials Based on Multientate Palladium Compounds[J]. Progress in Chemistry, 2023 , 35(9) : 1369 -1388 . DOI: 10.7536/PC230115

表1 不同磁性纳米颗粒负载的催化剂对Suzuki-Miyaura反应的性能Table 1 Performance of catalysts supported by different magnetic nanoparticles for Suzuka-Miyaura reaction |

| Pd catalyst (mol%) | Standard conditions | Yield(%) | Reusability | TOF(h-1) | ref |

|---|---|---|---|---|---|

| MNP-2 (0.14 mol% Pd) | K2CO3, EtOH/H2O(1∶1), 80 ℃, 50 min | 95% | 8 | 814.28 | 20a |

| MNP-3 (0.01 mol% Pd) | K2CO3, EtOH/H2O(1∶1), 70 ℃, 30 min | 96% | 12 | 19 200 | 21a |

| MNP-4 (0.1 mol% Pd) | Et3N or Na2CO3, EtOH/H2O(1∶1), 80 ℃, 30 min | 99% | 7 | 1980 | 22b |

| MNP-10 (0.009 mol% Pd) | K2CO3, EtOH/H2O(1∶1), 75 ℃, 1.0 h | 97% | 5 | 10 778 | 29a |

| MNP-12 (0.47 mol% Pd) | K2CO3, H2O, 60~90 ℃, 20 min | 95% | 6 | 612 | 31a |

| MNP-13 (0.1 mol% Pd) | K2CO3, H2O, 90 ℃, 1.0 h | 95% | 6 | 950 | 32a |

| MNP-14 (0.09 mol% Pd) | K2CO3, H2O, reflux, 1.0 h | 93% | 6 | 1033.3 | 33a |

| MNP-18 (0.01 mol% Pd) | Et3N, H2O, 80 ℃, 45 min | 91% | 9 | 12 133.3 | 39a |

| MNP-20 (0.04 mol% Pd ) | K2CO3, EtOH/H2O(2∶1), 60 ℃, 1.5 h | 95% | 7 | 1583.3 | 41a |

| MNP-21 (0.5 mol% Pd) | Et3N, DMF, 100 ℃, 3 h | 92% | 10 | 61.3 | 42a |

| MNP-23 (0.3 mol% Pd) | K2CO3, NMP, 100 ℃, 2.5 h | 88% | 8 | 117 | 44a |

| MNP-27 (0.017 mol% Pd) | K2CO3, EtOH/H2O(1∶1), 80 ℃, 3.0 h | 86% | 7 | 1686.3 | 49a |

| MNP-28 (0.34 mol% Pd) | K2CO3, EtOH/H2O(2∶1), 60 ℃, 3.0 h | 92% | 20 | 6903 | 50a |

| MNP-29 (0.825 mol% Pd) | K2CO3, NMP, 90 ℃, 1.0 h | 88% | 6 | 107 | 51a |

| MNP-34 (0.5 mol%) | K3PO4, Toluene, 100 ℃, 24.0 h | 99% | 7 | 8.25 | 55c |

| MNP-35 (0.15 mol% Pd) | K2CO3, EtOH/H2O(1∶1), 70 ℃, 1.0 h | 95% | 5 | 633.3 | 56a |

| MNP-36 (0.15 mol% Pd) | K2CO3, EtOH/H2O(1∶1), R.T, 2.0 h | 95% | 7 | 316.7 | 57a |

| MNP-37 (0.022 mmol% Pd ) | Na2CO3, EtOH, 60 ℃, 20 min | 95% | 5 | 12 954.5 | 58a |

| MNP-38 (0.021 mmol% Pd) | NaHCO3, EtOH/H2O(1∶1), 70 ℃, 10 min | 98% | 13 | 2940×104 | 59a |

| MNP-39 (0.37 mol% Pd ) | K2CO3, H2O, 60 ℃, 3.0 h | 96% | 8 | 86.5 | 60a |

| MNP-40-A (1.5 mol% ) | Na2CO3, PEG-400, 80 ℃, 100 min | 88% | 8 | 35.2 | 61a |

| MNP-40-B (0.83 mol% ) | Na2CO3, PEG-400, 80 ℃, 3.0 h | 93% | 7 | 37.3 | 62a |

| MNP-41 (0.5 mol%) | K2CO3, EtOH/H2O(2∶1), 60 ℃, 12.0 h | 93% | 12 | 15.5 | 63d |

a. Suzuki-Miyaura reaction of bromobenzene with phenylboronic acid.; b. Suzuki-Miyaura reaction of bromobenzene with 4-tolylboronic acid.; c. Suzuki-Miyaura reaction of 9-chloroacridine with phenylboronic acid.; d. Suzuki-Miyaura reaction of 4-chloroanisole with phenylboronic acid. |

表2 不同磁性纳米颗粒负载的催化剂对Heck反应的性能Table 2 Performance of catalysts supported by different magnetic nanoparticles for Heck reaction |

| Pd catalyst (mol%) | Standard conditions | Yield(%) | Reusability | TOF(h-1) | ref |

|---|---|---|---|---|---|

| MNP-5 (3.58 mol%) | K2CO3, DMF, 100 ℃, 8 h | 93% | 8 | 3.25 | 23a |

| MNP-6 (1.24 mol% Pd) | Et3N, DMSO, 100 ℃, 1.5 h | 92% | 6 | 49 | 24a |

| MNP-10 (0.009 mol% Pd) | Et3N, Solvent-free, 120 ℃, 40 min | 96% | 5 | 16000 | 29b |

| MNP-12 (0.61mol% Pd) | K2CO3, H2O, 80~90 ℃, 50 min | 95% | 6 | 187 | 31c |

| MNP-13 (0.1 mol% Pd) | K2CO3, H2O/DMF(1∶1), reflux, 8.0 h | 95% | 6 | 122.5 | 32a |

| MNP-14 (0.09 mol% Pd) | K2CO3, H2O, reflux, 12 h | 96% | 6 | 88.8 | 33d |

| MNP-15 (0.71 mol% Pd) | Et3N, DMF, TBAB, 120 ℃, 20 min | 93% | 10 | 393 | 34b |

| MNP-19 (0.15 mol% Pd ) | Et3N, DMF, 120 ℃, 45 min | 98% | 5 | 871.1 | 40b |

| MNP-21 (0.5 mol% Pd) | Et3N, DMF, 100 ℃, 0.25 h | 98% | 10 | 784 | 42c |

| MNP-23 (0.3 mol% Pd) | K2CO3, DMF, 110 ℃, 0.75 h | 97% | 8 | 430 | 44c |

| MNP-24 (0.2 mol% Pd) | K2CO3, H2O/DMF(2∶1), 90 ℃, 0.5 h | 95% | 8 | 950 | 45c |

| MNP-25 (0.08 mol% Pd) | NaOAc, H2O, R.T., 1.0 h | 98% | 10 | 1225 | 46a |

| MNP-29 (0.99 mol% Pd ) | K2CO3, NMP, 110 ℃, 0.5 h | 96% | 6 | 194 | 51c |

| MNP-30 (0.0435 mol% Pd) | NaOAc, H2O, R.T., 1.0 h | 95% | 10 | 2183.9 | 52a |

| MNP-36 (1.0 mol% Pd) | Na3PO4·12H2O, MeCN, 80 ℃, 4.0 h | 96% | 7 | 24 | 57e |

| MNP-40-A(2.27 mol% ) | Na2CO3, PEG-400, 120 ℃, 80 min | 96% | 7 | 31.7 | 61c |

| MNP-40-B(1.46 mol% ) | Na2CO3, PEG-400, 120 ℃, 1.0 h | 98% | 7 | 67.1 | 62c |

a. R=Ph; b. R=COOMe; c. R=COOBun; d. R=COOH; e. R=COOtBu |

表3 不同磁性纳米颗粒负载的催化剂对其他C-C偶联反应的性能Table 3 Performance of catalysts supported by different magnetic nanoparticles for other C-C coupling reactions |

| Pd catalyst (mol%) | Standard conditions | Yield(%) | Reusability | TOF(h-1) | ref |

|---|---|---|---|---|---|

| MNP-21(0.5 mol% Pd) | Et3N, DMF, 100 ℃, 1.5 h | 96% | 10 | 128 | 42a |

| MNP-18(0.1 mol% Pd) | Et3N, H2O, 80 ℃, 0.5 h | 90% | 9 | 1800 | 42b |

| MNP-18(0.2 mol% Pd) | Et3N, H2O, 80 ℃, 6.0 h | 99% | 9 | 82.5 | 42c |

| MNP-22 (0.7 mol% Pd) | Et3N, DMF, 90 ℃, 0.5 h | 94% | 6 | 268.6 | 43a |

| MNP-24 (0.2 mol% Pd) | K2CO3, H2O/DMF(2∶1), 90 ℃, 1.0 h | 96% | 8 | 480 | 45a |

| MNP-25 (0.08 mol%) | NaOAc, H2O, R.T., 1.0 h | 94% | 10 | 1175 | 46a |

| MNP-30(0.0435 mol% Pd) | NaOAc, H2O, R.T., 1.0 h | 95% | 10 | 2184 | 52a |

| MNP-39(0.43 mol% Pd ) | Piperidine, Solvent-free, 90 ℃, 1.5 h | 95% | 8 | 147.3 | 60a |

a. Sonogashira reaction of Iodobenzene with phenylacetylene; b. Cyanation Reaction of Iodobenzene with K4[Fe(CN)6]·3H2O;c. Hiyama Cross-Coupling Reaction of Halobenzenes with Triethoxyphenylsilane. |

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

( (刘杰, 朱庆仁, 杜娟, 张袖丽. 有机化学, 2015, 35(1): 15.)

|

| [14] |

|

| [15] |

(乔妮娜. 广东药科大学硕士论文, 2019.).

|

| [16] |

( 颜廷良, 张玉, 朱啸庆, 张雪华, 刘总堂, 戴兢陶, 徐国栋. 扬州大学学报(自然科学版), 2022, 25(1): 19.)

|

| [17] |

母佳利, 胡庭维, 陕绍云, 蒋利红, 王亚明, 贾庆明. 高分子材料科学与工程, 2013, 29(7): 179.).

|

| [18] |

(王海博. 兰州大学硕士论文, 2013.).

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

/

| 〈 |

|

〉 |