Metal Nanocluter Catalysts for Hydrogenation of Carbon Dioxide to Multicarbon Compounds

Received date: 2023-01-02

Revised date: 2023-05-22

Online published: 2023-06-10

Supported by

The National Natural Science Foundation of China(91961103)

The National Natural Science Foundation of China(21821004)

The Beijing National Laboratory for Molecular Sciences(BNLMS-CXXM-202001)

The National Key Research and Development Program(2021YFA1501000)

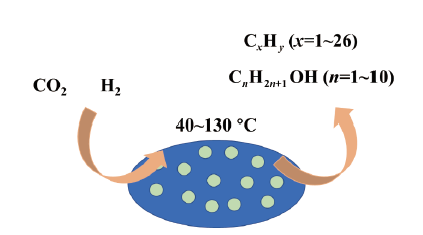

Selectively catalytic hydrogenation of CO2 to multi-carbon compounds is of great significance for reducing carbon dioxide emissions and regenerating carbon-containing resources. In this review, we summarize the development of catalytic systems for CO2 hydrogenation to multi-carbon compounds in recent years. The development of metal nanocluster catalysts for CO2 hydrogenation to multi-carbon hydrocarbons or alcohols at low temperatures are introduced, and the chemical basis for regulating C1 and C2+ product selectivity in CO2 hydrogenation is discussed. The progresses in preparing and understanding the structure-function relationship of Pt-Ru bimetallic nanocluster catalysts with the high selectivity for C2+ compounds in the CO2 hydrogenation at low temperatures are discussed. Finally, we elaborate the theory of local charge distribution effect of metal nanocluster catalysts.

1 Introduction

2 Performance and conversion pathways of CO2hydrogenation over metal nanocluster catalysts at low temperatures

3 Chemical basis for controlling the product selectivity

4 Preparation and properties of a highly selective PtRu bimetallic nanoclusters catalyst

5 Structural characteristics of active sites of metal nanoclusters

6 Conclusion and perspective

Yuan Wang , Yulv Yu , Xin Tan . Metal Nanocluter Catalysts for Hydrogenation of Carbon Dioxide to Multicarbon Compounds[J]. Progress in Chemistry, 2023 , 35(6) : 918 -927 . DOI: 10.7536/PC221235

图1 (A~C) Ru-Pt/FeCO3的透射电镜照片、高分辨透射电镜照片和高角度环形暗场扫描透射电镜照片,(D) C图中选区高分辨照片,(E~G) 选区内Pt、Fe和Ru的元素分布图,(H) 图E和图G的合并图片[28]Fig.1 (A~C) TEM image, high-resolution TEM image, and HAADF-STEM image of Ru-Pt/FeCO3, (D) High-resolution TEM image of the selected area in (C), (E~G) EDX elemental mapping of Pt, Fe, and Ru in the same area, (H) Merged image of (E) and (G)[28]. Reproduced from Ref. 28 with permission from the Royal Society of Chemistry |

图2 (A)在不同温度下Ru-Pt/FeCO3催化CO2氢化产物分布图, (B)该催化体系中CO2氢化生成甲烷和多碳化合物的表观活化能[28]Fig.2 (A) Product distributions for CO2 hydrogenation over Ru-Pt/FeCO3 at different temperatures. (B) Apparent activation energy measurements for the formation of methane and higher hydrocarbons (C2+) in CO2 hydrogenation over Ru-Pt/FeCO3, respectively[28]. Reproduced from Ref. 28 with permission from the Royal Society of Chemistry |

图4 (A, B)在18O标记水中Ru-Pt/Fe3O4催化CO2氢化反应生成的丙醇和丁醇的质谱图,(C)低温下金属烷基水解生成多碳醇的反应途径示意图[30]Fig.4 (A, B) The mass spectra of propanol and butanol formed in CO2 hydrogenation over Ru-Pt/Fe3O4 in18O labeled water, (C) reaction mechanism for multi-carbon alcohols formation based on metal-alkyl hydrolysis over Ru-Pt/Fe3O4[30] |

图6 (A) Ru-co-Pt/C的高角度环形暗场扫描透射电镜照片,(B~D) 选区中Pt、Ru以及Pt和Ru叠加的元素分布图像,(E) 选区中金属纳米粒子的原子级分辨图像,(F) Ru-co-Pt模型,其中红色球代表一列原子柱中主要含有Pt原子,绿色球代表一列原子柱中主要含有Ru原子,(G) E图中选区中粒子的放大图像,(H) 双金属纳米粒子中原子(或柱)Z-衬度线扫分析结果[31]Fig.6 (A) The HAADF-STEM image of Ru-co-Pt/C. (B~D) Energy dispersive X-ray spectroscopy (EDX) elemental mapping image of Pt (B), Ru (C), and Pt + Ru (D) in the selected area. (E) The atomic-resolution HADDF-STEM image of a typical particle in the selected area. (F) A model for the structure of Ru-co-Pt, in which the atom columns mainly composed of Pt and Ru are marked with red and green balls, respectively. (G) The enlarged HAADF-STEM image of the selected typical bimetallic particle in (E). (H) Line scan Z-contrast analysis of atom columns in the bimetallic nanoparticle in (E) along the arrow in (F)[31]. Reproduced from Ref. 31 with permission from the Royal Society of Chemistry |

图7 (A,B) Ru-co-Pt/C中Ru和Pt的X射线光电子能谱图, (C, D) Ru-co-Pt/C样品的Ru K边和Pt L3边的扩展X射线吸收精细结构谱图[31]Fig.7 (A, B) XPS spectra of Ru 3d (A) and Pt 4f levels (B) in Ru-co-Pt/C, respectively. (C, D) Fourier transform (FT) EXAFS spectra of Ru K edge (C) and Pt L3 edge (D) for Ru-co-Pt/C, respectively[31]. Reproduced from Ref. 31 with permission from the Royal Society of Chemistry |

图8 (A)Ru-co-Ru/C、Pt-co-Pt/C和Ru-co-Pt/C三种催化剂催化CO2加氢反应性能,(B)Ru-co-Pt/C在不同温度下催化CO2加氢反应性能,(C)Ru-co-Pt/C在130℃下催化CO2加氢稳定性测试,(D~F)Ru-co-Ru/C、Pt-co-Pt/C和Ru-co-Pt/C催化CO2加氢生成的产物分布图,Wn代表Cn物质的质量分数[31]Fig.8 (A) Catalytic performance of Ru-co-Ru/C, Pt-co-Pt/C, and Ru-co-Pt/C in CO2 hydrogenation, respectively. (B) Catalytic performance of Ru-co-Pt/C in CO2 hydrogenation at different temperatures. (C) The stability of Ru-co-Pt/C in CO2 hydrogenation at 130℃. (D~F) Product distributions in CO2 hydrogenation over Ru-co-Ru/C (D), Pt-co-Pt/C (E), and Ru-co-Pt/C (F) at 130℃, respectively. Wn represents the mass percentage of Cn compounds in the products [31]. Reproduced from Ref. 31 with permission from the Royal Society of Chemistry |

表1 由DFT理论计算获得的CO2氢化反应中若干基元反应能垒[31]Table 1 The energy barriers of several primitive reactions in CO2 hydrogenation calculated via DFT. [31] Reproduced from Ref. 31 with permission from the Royal Society of Chemistry. |

| Catalyst | Reaction energy barriers (eV) | ||

|---|---|---|---|

| CH2+CH2 coupling | CH2 + H | CH3 +H | |

| Pt42-Ru8 | 0.31 | 0.55 | 0.53 |

| Ru50 | 1.44 | 0.85 | 0.77 |

| Pt50 | 0.78 | 0.92 | 0.81 |

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

( 王鹏, 刘欢, 杨妲. 化学进展, 2022, 34(5): 1076.).

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

/

| 〈 |

|

〉 |