High-Sensitivity Flexible Pressure Sensor Based on Micro-Nano Structure

Received date: 2022-10-25

Revised date: 2023-02-24

Online published: 2023-04-30

Supported by

National Natural Science Foundation of China(22078188)

Xianyang City Qin Chuangyuan Science and Technology Innovation Special Project(2021ZDZX-GY-0007)

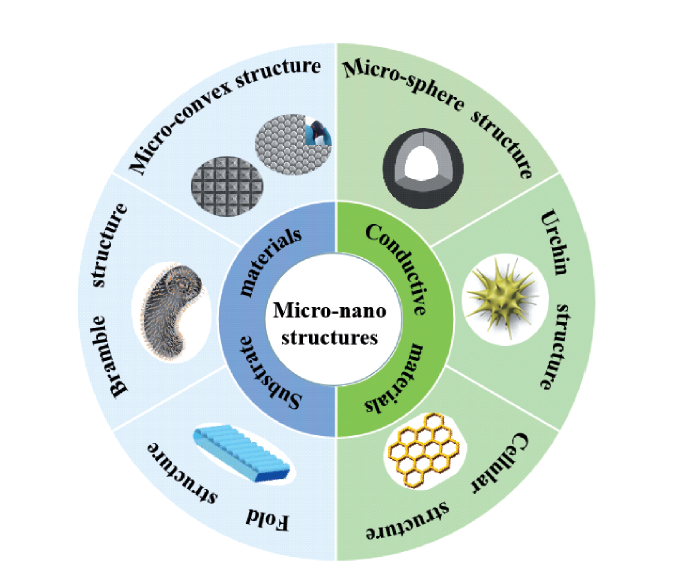

In recent years, with the development and popularization of Internet and artificial intelligence, the flexible pressure sensor with light, convenience and excellent electronic performance, as the core device of wearable electronic equipment, has a increasingly broad market. Flexible pressure sensors have attracted extensive attention in electronic skin, motion detection, medical monitoring and man-machine interface because of its flexibility, folding and excellent sensing performance. The construction of micro-nano structures is the key to improve the sensitivity and sensing performance of pressure sensors. Based on this, the sensing mechanism (piezoresistive, capacitive, piezoelectric, triboelectric) and key performance parameters (sensitivity, pressure response range, detection limit, response/recovery time, stability of circulation and linearity, etc.) of the high-sensitivity pressure sensors were summarized. Then, research progress of flexible pressure sensors using substrates to construct surface micro-nano structures (micro-convex structure, bramble structure and fold structure) and using conductive materials to construct micro-nano structures (micro-sphere structure, urchin structure and cellular structure) were compared and concluded. Furthermore, the application status of high-sensitivity flexible pressure sensors based on micro-nano structure in pulse detection, electronic skin, motion detection and man-machine interface was concluded. Finally, from the perspective of future application, the challenges and development direction of high sensitivity flexible pressure sensor are summarized.

1 Introduction

2 Sensing mechanism and key performance parameters of high sensitivity flexible pressure sensor

2.1 Sensing mechanism

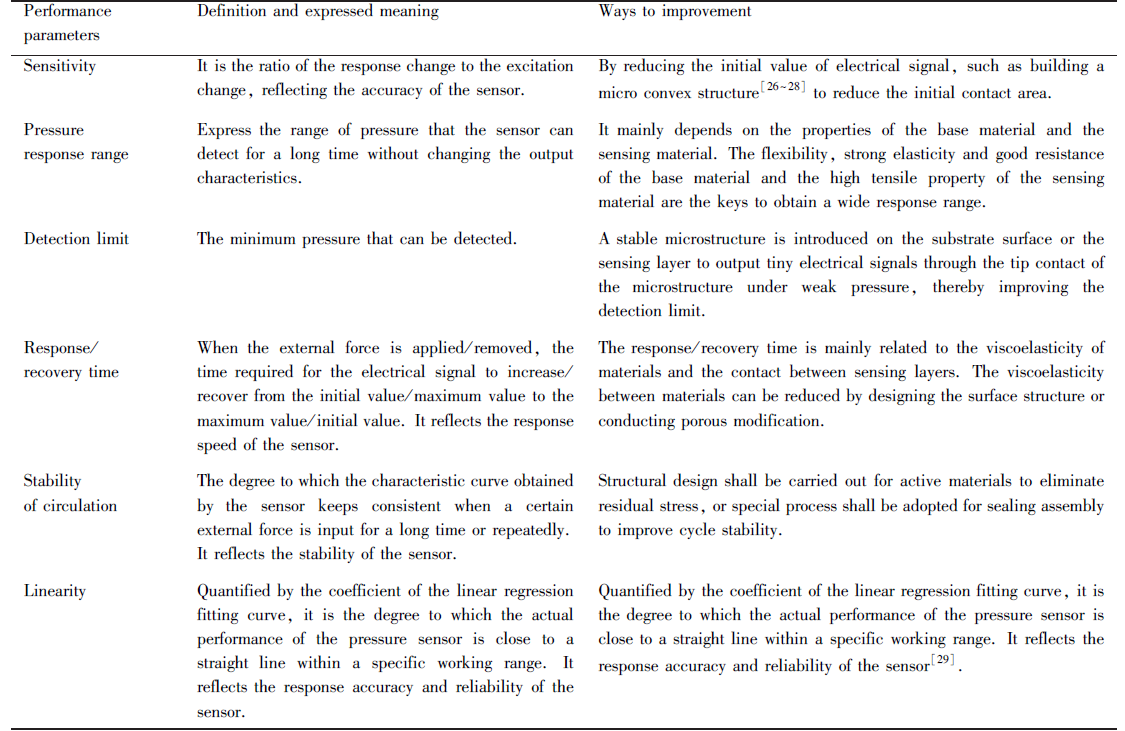

2.2 Key performance parameters

3 Construction of high sensitivity flexible pressure sensor based on micro-nano structure of substrate materials

3.1 Micro-convex structure

3.2 Bramble structure

3.3 Fold structure

4 Construction of high sensitivity flexible pressure sensor based on micro-nano structure of conductive materials

5 Application of high sensitivity flexible pressure sensor based on micro-nano structure

6 Summary and outlook

Key words: flexible pressure sensor; high sensitivity; micro-nano structure

Yan Bao , Jiachen Xu , Ruyue Guo , Jianzhong Ma . High-Sensitivity Flexible Pressure Sensor Based on Micro-Nano Structure[J]. Progress in Chemistry, 2023 , 35(5) : 709 -720 . DOI: 10.7536/PC221014

表1 柔性压力传感器的关键性能参数Table 1 Key performance parameters of flexible pressure sensor |

|

图3 基于微穹顶CNTs/PDMS薄膜的压力传感器:(a)微穹顶CNT/PDMS薄膜的制备过程;(b)传感机理图;(c)传感性能比较[38]Fig. 3 Sensitivity curve of pressure sensor based on micro dome CNTs/PDMS film: (a) preparation process of CNT/PDMS thin films for micro dome; (b) preparation process of CNT/PDMS thin films for micro dome; (c) comparison of sensing performance[38] |

图7 基于褶皱结构的电容式压力传感器:(a~c)无褶皱、单侧褶皱和双侧褶皱压力传感器在5 kPa压力下的传感性能;(d~f)无褶皱、单侧褶皱和双侧褶皱压力传感器的响应时间;(g)传感器的制备过程示意图[47]Fig. 7 Capacitive pressure sensor based on pleated structure. (a~c) Sensing performance of wrinkle free, unilateral wrinkle and bilateral wrinkle pressure sensors under 5 kPa pressure; (d~f) response time of non fold, unilateral fold and bilateral fold pressure sensors; (g) schematic diagram of sensor preparation process[47] |

表2 基于微纳结构的高灵敏度压力传感器的性能Table 2 Performance of high sensitivity pressure sensor based on micro-nano structure |

| Micro-nano structure | Sensitivity/ kPa-1 | Detection range/kPa (Detection limit/Pa) | Response (recovery) time/ms | Cycle stability/ times | Application | ref | |

|---|---|---|---|---|---|---|---|

| Basal material | None | 5.24 | 0~16 | 40/380 | > 3000 | Bend the wrists, elbows, and knees | 49 |

| Micro dome structure | 6.61 | 0~0.11(1) | 100/100 | > 3750 | Finger click mouse, finger joint movement | 50 | |

| 0.19 | 0~100(500) | 75/80 | > 1000 | Pulse, finger clicks, grip strength, and plantar pressure | 37 | ||

| 15.1 | 0~59(0.2) | 40/40 | > 1000 | Health testing, exercise monitoring | 38 | ||

| Micro vertebral structure | 3.26 | 0~3 | 200/100 | > 5000 | Various textures, such as the texture of different fabrics, Braille, etc | 40 | |

| 2.51 | 0~10(2) | 84/117 | > 5000 | Muscle activity and skipping rope | 51 | ||

| Micro cylindrical structure | 419.6 | 0~0.1 | 31/15 | > 1000 | Swallowing and pulse | 52 | |

| 0.6 | (0.06) | 25/25 | > 10000 | Pulse, body movement, breathing, etc | 41 | ||

| Thorns structure | 179.1 | 0~50(1.2) | 400/400 | > 10000 | Heart rate and respiratory monitoring | 46 | |

| 1127 | - | 200/250 | > 2000 | Real-time posture signals were recorded at the lumbar and cervical spine | 45 | ||

| Fold structure | 2.59 | 0~20(1) | 10/20 | > 3000 | Clenching and joint movements | 53 | |

| 228.5 | 0~10(2.97) | 66.8 | > 10000 | Pulse, finger movement | 48 | ||

| Conductive material | Micro ball | 924.37 | 0~220(0.83) | - | > 22000 | Physiological signals such as arteries | 59 |

| Empty core ball | 0.55 | 0~5 | 41 | > 1200 | Pulse and body movement | 60 | |

| The sea urchin shaped | 680 | 0~150(83) | 10/22 | > 3500 | Pulse, pronunciation, palm and finger movements, walking | 64 | |

| Honeycomb | 161.6 | 0~10(9) | - | > 200 | Artificial skin | 67 |

| [1] |

|

| [2] |

|

| [3] |

(郭茹月, 鲍艳. 精细化工, 2021, 38(04): 649.).

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

(王宇捷. 当代化工研究, 2018, (09): 122.).

|

| [9] |

|

| [10] |

(鲁戈舞, 陈凤恩, 吴旭峰, 曲良体, 张家鑫, 石高全. 科学通报, 2005, 50(15): 1545.).

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

(戴鸿飞. 长春工业大学硕士论文, 2022.).

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

(鲍艳, 郑茜, 郭茹月. 化工进展, 2022, 41(07): 3624.).

|

| [56] |

|

| [57] |

(乐园, 陈建峰, 汪文川. 化工进展, 2004,(06): 595.).

|

| [58] |

(吴素心, 张雄志, 喻尧. 化学与生物工程, 2021, 38(12): 41.).

|

| [59] |

|

| [60] |

|

| [61] |

(鲍艳, 李欣倩. 化工新型材料, 2018, 46(12): 42.).

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

(雷鹏, 鲍艳. 材料导报, 2022, 36(14): 82.).

|

| [73] |

|

| [74] |

|

| [75] |

|

| [76] |

|

| [77] |

|

| [78] |

|

| [79] |

|

/

| 〈 |

|

〉 |