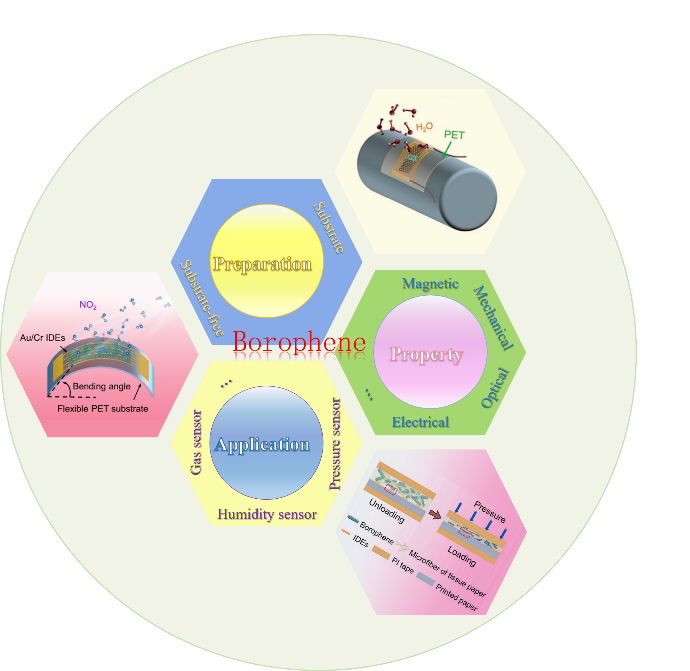

Experimental Preparation of Borophene and Its Application in Sensors

Received date: 2024-01-26

Revised date: 2024-04-02

Online published: 2024-06-29

Supported by

National Natural Science Foundation of China(61774085)

Natural Science Foundation of Jiangsu Province(BK20201300)

Priority Academic Program Development of Jiangsu Higher Education Institutions.

borophene,as an emerging single-element two-dimensional material,has attracted great interest from researchers due to its excellent properties such as high carrier mobility,mechanical compliance,optical transparency,ultrahigh thermal conductivity,and superconductivity.These properties make it an ideal candidate for research fields such as energy,sensors,and information storage.Guided by the pioneering experimental work in 2015,new achievements in experimental synthesis and practical applications of borophene continue emerging,which has driven the development of borophene from experimental synthesis to practical applications.based on the introduction of the special properties and innovative synthesis methods,we mainly review the application of borophene in the field of sensors.Finally,some reasonable discussions on potential issues and challenges for future researches are provided Based on the current state of research。

Contents

1 Introduction

2 Characteristics of borophene

2.1 Electrical properties

2.2 Optical properties

2.3 Mechanical properties

2.4 Magnetic properties

3 Preparation of borophene

3.1 Synthesis of borophene on substrate surface

3.2 Substrate-free synthesis of borophene

4 The application of borophene in sensors

4.1 Borophene gas sensor

4.2 Borophene pressure sensor

4.3 Borophene heterojunction humidity sensor

5 Conclusion and outlook

Key words: two-dimensional material; borophene; pressure sensor; humidity sensor; gas sensor

Shifan Chen , Yi Liu , Xiang Liu , Qian Tian , Guoan Tai . Experimental Preparation of Borophene and Its Application in Sensors[J]. Progress in Chemistry, 2024 , 36(8) : 1119 -1133 . DOI: 10.7536/PC240122

表1 Characteristics and Applications of New Two-dimensional Materials[15⇓⇓⇓⇓⇓~21]Table 1 Characteristics and applications of two-dimensional materials[15⇓⇓⇓⇓⇓~21] |

| 2D Materials | Structural characteristics | Physical characteristics | Potential application | ref |

|---|---|---|---|---|

| Borophene | Structural diversity More stable after hydrogenation | Dirac cones Larger Young’s modulus Superconductivity | Energy storage Nanoscale gas sensor Biomedical applications | 15 |

| Silicene | Low buckled geometry | Dirac cones High Fermi velocity and carrier mobility Spin-orbit coupling Ambipolar Dirac charge transport | Field effect transistor Spintronic devices | 16 |

| Germanene | Low buckled geometry | Resistance to atmospheric oxidation | Energy storage and catalysis | 17 |

| Phosphorene | Vertically skewed/wrinkled honeycomb structure | Semiconductor with a predicted direct bandgap Layer dependent photoluminescence Superior mechanical flexibility | Phosphorene-based devices | 18,19 |

| Hexagonal boron nitride | Hexagonal structure | Electrical insulation Excellent thermal conductivity | Substrates and gate dielectrics for 2D electronics applications Super-capacitor | 20 |

| Transition metal dihalides | Containing triangular and honeycomb transition metal nets | High temperature paramagnetic behavior | Kitaev spin liquid | 21 |

图1 γ-B28硼烯的示意图及物理特性表征:(a)γ-B28硼烯的制备与结构示意图;(b)AFM图像;(c)FFT图像;(d)紫外-可见(UV-Vis)吸收光谱;(e)室温光致发光(PL)光谱[61]Fig. 1 Schematic diagram and physical characterization of γ-B28 borophene: (a) Schematic diagram of preparation and structure of γ-B28 borophene; (b) AFM images; (c) FFT images; (d) Ultraviolet-visible (UV-Vis) absorption spectrum; (e) Room temperature photoluminescence (PL) spectrum[61]. Copyright 2015 John Wiley and Sons |

图3 云母衬底上硼烯的晶体结构:(a)硼烯和云母的原子结构图;(b)α′-2H硼烯的结构;(c)硼烯的AFM图像;(d)硼烯的HRTEM图像;(e)硼烯的TEM图像。插图为相应的SAED图像[80]Fig. 3 Crystal structure of borophene on mica substrates: (a) Atomic structure diagram of borophene and mica; (b) Structure of α′-2H borophene; (c) AFM image of borophene; (d) HRTEM image of borophene; (e) TEM image of borophene. Corresponding SAED images are shown as insets[80]. Copyright 2021 ACS Publications |

图4 在DMF(a, b)和IPA(c, d)中进行尖端超声处理4 h后,分别在5000 r/min下离心30 min,所制备的少层B纳米片的典型TEM图像。(a)、(c)和(d)的插图显示了所选区域相应的FFT模式[81]Fig. 4 Typical TEM images of few-layer B nanosheets prepared by 4 h tip ultrasonication in DMF (a, b) and IPA (c, d), followed by centrifugation at 5000 r/min for 30 min. The insets in (a), (c), and (d) display the corresponding FFT patterns of the selected regions[81].Copyright 2018 ACS Publications |

图5 原位热分解合成αʹ-4H-硼烯:(a)SEM图像;(b)扫描电镜测得的80张纳米片横向尺寸统计数据;(c)AFM图像;(d)低分辨率TEM图像;(e)HRTEM图像和相应的SAED图像;(f)对(e)中红色矩形区域提取的FFT模式进行重构后的HRTEM图像[83]Fig. 5 Synthesis of αʹ-4H-borophene by in-situ thermal decomposition: (a) SEM image; (b) Statistical data of lateral dimensions of 80 nanosheets measured by SEM; (c) AFM image; (d) Low-resolution TEM image; (e) HRTEM image and corresponding SAED pattern; (f) Reconstructed HRTEM image of the FFT pattern extracted from the red rectangular region in (e)[83]. Copyright 2020 John Wiley and Sons |

图6 硼烯-石墨烯异质结构的形貌和结晶度:(a~c)少层石墨烯、硼烯和硼烯-石墨烯异质结构的SEM图像;(d)典型异质结构的低分辨率TEM图像;(e)硼烯的低分辨率TEM图像;(f)从(e)中绿色矩形区域提取的HRTEM图像。插图为从计算模型中提取的相应SAED图像和HRTEM图;(g~i)异质结构的STEM-HAADF-EDS元素映射[85]Fig. 6 Morphology and crystallinity of borophene-graphene heterostructures: (a~c) SEM images of few-layer graphene, borophene, and borophene-graphene heterostructure; (d) Low-resolution TEM image of a typical borophene-graphene heterostructure; (e) Low-resolution TEM image of borophene; (f) HRTEM image extracted from the green rectangular region in (e). Insets show the corresponding SAED patterns and HRTEM images obtained from computational models; (g~i) STEM-HAADF-EDS elemental mapping of the borophene-graphene heterostructure[85]. Copyright 2020 Springer Nature |

图7 (a~e)硼烯表面气体吸附(CO、NO、CO2、NO2、NH3)的电荷密度差图。红色表面表示电子获得,蓝色表面表示电子损失;(f)零偏压传输原始硼烯和硼烯+气体系统;(g)硼烯单层随不同吸附气体分子变化的I-V特性曲线[86]Fig. 7 (a~e) Charge density difference maps of gas adsorption (CO, NO, CO2, NO2, NH3) on the surface of borophene. Red surfaces indicate electron gain, while blue surfaces indicate electron loss; (f) Zero-bias transmission of pristine borophene and borophene+gas system; (g) I-V characteristics of monolayer borophene with different adsorbed gas molecules[86].Copyright 2017 ACS Publications |

图10 硼烯-石墨烯异质结构湿度传感器:(a)基于硼烯-石墨烯异质结的传感器示意图;(b)不同相对湿度下异质结构传感器的湿度传感行为;(c)暴露于不同相对湿度下的异质结构传感器的灵敏度;(d)异质结构传感器在85% RH下的响应和恢复曲线;(e)PET衬底上弯曲异质结构传感器的示意图;(f)无弯曲应变和有弯曲应变时传感器的响应曲线[85]Fig. 10 Borophene-graphene heterostructure humidity sensor: (a) Schematic representation of the sensor based on borophene-graphene heterostructure; (b) Humidity sensing behavior of the heterostructure sensor at different relative humidities; (c) Sensitivity of the heterostructure sensor exposed to different relative humidities; (d) Response and recovery curves of the heterostructure sensor under 85% RH; (e) Schematic diagram of the bent heterostructure sensor on a PET substrate; (f) Response curves of the sensor with and without applied bending strain[85]. Copyright 2020 Springer Nature |

图11 硼烯-BC2N异质结构湿度传感器:(a)不同相对湿度下传感器的实时响应;(b)不同相对湿度下的长效响应;(c)指尖接近不同距离时传感器的实时电流曲线[97]Fig. 11 Borophene-BC2N heterostructure humidity sensor: (a) Real-time response of the sensor at different humidity levels; (b) Long-term response of the sensor at different humidity levels; (c) Real-time current curve of the sensor as the fingertip approaches at different distances[97]. Copyright 2023 RSC Society of Chemistry |

表3 Performance Comparison of Typical Two-dimensional Material Resistive Humidity Sensors[85,97⇓⇓⇓~101]Table 3 humidity sensing performances of some typical two-dimensional material resistive Humidity sensors[85,97⇓⇓⇓~101] |

| Material | Sensitivity (%) | Response (s) / Recovery (s) | RH range (%) | ref |

|---|---|---|---|---|

| Graphene | 0.3 | 0.6/0.4 | 1~96 | 98 |

| rGO | 20.4 | 180/Irreversible | 10~100 | 99 |

| Black phosphorus | 521 | 101/26 | 11~97 | 100 |

| MoS2 | 2327 | 140/80 | 17.2~89.5 | 101 |

| α'-4H-Borophene | 150 | 2.3/0.7 | 67~85 | 85 |

| Borophene-graphene | 4200 | 10.5/8.3 | 0~85 | 85 |

| Borophene-BC2N | 22 001 | 11.82/1.41 | 11~97 | 97 |

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

| [74] |

|

| [75] |

|

| [76] |

|

| [77] |

|

| [78] |

|

| [79] |

|

| [80] |

|

| [81] |

|

| [82] |

|

| [83] |

|

| [84] |

|

| [85] |

|

| [86] |

|

| [87] |

|

| [88] |

|

| [89] |

|

| [90] |

|

| [91] |

|

| [92] |

|

| [93] |

|

| [94] |

|

| [95] |

|

| [96] |

|

| [97] |

|

| [98] |

|

| [99] |

|

| [100] |

|

| [101] |

|

/

| 〈 |

|

〉 |