MXene-Based Functional Textile Composites

Received date: 2024-01-04

Revised date: 2024-03-27

Online published: 2024-07-01

Supported by

Shanxi Province Basic Research Program(20210302124684)

Shanxi Province Returned Overseas Educated Personnel Research Grant Program(2023-049)

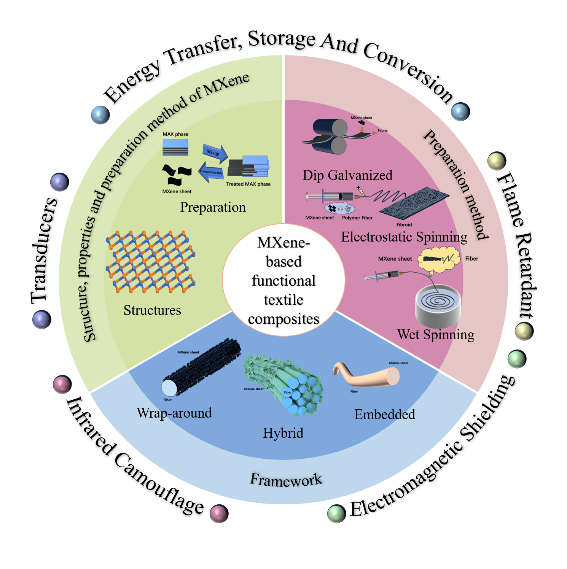

the novel two-dimensional metal carbon/nitride MXene,owing to its unique two-dimensional structure and performance,can be composite with various textile materials,imparting excellent conductivity,mechanical properties,etc.,to textile composite materials.Therefore,It has shown tremendous development potential in fields such as sensing,electromagnetic shielding,and energy storage.This article initially introduces the structure,preparation methods,and properties of MXene.It provides a summary of the preparation methods for MXene-based functional textile composite materials,including coating methods,electrospinning,wet spinning,vacuum filtration,etc.the article outlines the impact of different structures(coating,embedding,hybrid)of MXene-based functional textile composites on their performance.It also reviews their applications in sensors,electromagnetic shielding,energy transmission,and conversion.Finally,the article offers a prospect of the development trends in the research field of MXene-based functional textile composite materials。

Contents

1 Introduction

2 Structure and properties of MXene and its preparation methods

2.1 Structure

2.2 Preparation methods

2.3 Properties

3 Preparation of MXene-based functional textile composites

3.1 Coating

3.2 Electrostatic spinning

3.3 Wet spinning

3.4 Other methods

4 Structure of MXene-based functional textile composites

4.1 Wrap-around construction

4.2 Embedded Architecture

4.3 Hybrid structure

5 Applications of MXene-based functional textile composites

5.1 Transducers

5.2 Energy transfer,storage and conversion

5.3 Electromagnetic shielding

5.4 Other applications

6 Conclusions and outlook

Key words: MXene; textile composites; preparation methods; structure; properties; applications

Suqin Zhou , Lu Jia , Chuanjin Shi , Aiqin Zhang , Shuqiang Liu , Hua Wang . MXene-Based Functional Textile Composites[J]. Progress in Chemistry, 2024 , 36(8) : 1157 -1173 . DOI: 10.7536/PC240102

表1 Preparation Methods, Materials, Structures and Applications of Functional Textile Composites Based on MXeneTable 1 Preparation methods,materials,structures,and applications of MXene-based functional textile composites |

| MXene textile composite material preparation method | Materials | Framework | Applications | ref |

|---|---|---|---|---|

| Coating method | MXene/cotton fabric MXene/polyamide fiber MXene/polyester fiber MXene/carbon fiber MXene/sodium alginate/viscose MXene/epoxy resin/fiberglass MXene/carbon nanotube/basalt fiber MXene/cotton fiber | Wrap-around construction/Semi-flush construction/ Hybrid Structure | sensors, electromagnetic shielding, supercapacitors, thermal camouflage, radiant heating, photothermal conversion | 61,71 72 73 93 96 98 105 113 |

| Electrostatic Spinning | MXene/polyacrylonitrile/carbon nanofiber MXene/silver nanoparticles/polyacrylonitrile MXene/cellulose nanocrystals/polyvinyl alcohol | Embedded architecture/Semi-Embedded Architecture | piezoresistive sensors, supercapacitor electrodes, electromagnetic shielding lithium ion battery electrode materials | 77 81 80 |

| Wet Spinning | MXene MXene/carbon nanotubes/thermoplastic Polyurethane MXene/graphene MXene/kevlar MXene/graphene oxide | Embedded architecture/ Hybrid architecture | energy storage, biosensors, supercapacitors, artificial fiber tissue, neuroelectronic, respiration detection, temperature response | 47,84,85 86 87 88 115 |

| Thermal stretching after film formation | MXene/polyvinylidene fluoride | Embedded architecture | friction nanogenerators, sensors | 89 |

| Biscrolling | MXene/carbon nanotube | Wrap-around construction/ Hybrid construction | powerful woven electrodes for wearable e-textiles, batteries and fuel cells | 90,91,92 |

| 3D printing | MXene/TOCNFs | Hybrid structure | sensors, wearable heated textiles, human health monitoring | 94 |

| Coating method / Electrostatic Spinning | MXene/cotton/polyacrylonitrile | Hybrid structure | pressure sensors, electric heaters | 82 |

图4 MXene涂层棉压力传感织物的表征。(a)MXene 涂层棉质压力传感织物示意图:(上)表面粗糙的裸棉织物;(下)涂覆MXene后的棉织物。(b、c)涂覆MXene前后棉织物的FESEM图像。(d)MXene涂层棉质压力感应织物的数码照片和微结构表面的光学显微镜图像。(e)涂有MXene的棉质压力感应织物与LED灯泡连接,形成串联电路。轻轻触摸或弯曲织物后,LED灯泡的亮度会发生变化[11]Fig. 4 Characterization of the MXene-coated cotton pressure-sensing fabric. (a) Schematic of the MXene-coated cotton pressure-sensing fabric: (top) woven bare cotton fabric with a rough surface; (bottom) cotton fabric after coating with MXene. (b, c) FESEM images of the cotton fabric before and after coating with MXene. (d) Digital photograph of MXene-coated cotton pressure-sensing fabric and optical microscopy images of the microstructured surface. (e) MXene-coated cotton pressure-sensing fabric connected to an LED bulb to form a series circuit. The brightness of the LED bulb changes after gently touching or bending the fabric[11] |

图6 (a) MXene/GO 混合纤维的纺丝过程示意图;(b) MXene/GO 凝胶纤维从喷嘴到熔池的状态照片;(c) 长度超过 1.2 米的缠绕MXene/GO 混合纤维线轴;(d) 显示 MXene/GO 纤维(40 wt% MXene)柔韧性和可弯曲性的照片[125]Fig. 6 (a) Schematic illustration of the spinning process for MXene/GO hybrid fiber, (b) photograph of MXene/GO gel fiber states from the nozzle to the bath, (c) a bobbin of wound MXene/GO hybrid fibers over 1.2 m long, and (d) photograph showing the flexibility and bendability of an MXene/GO fiber (40 wt% MXene)[125] |

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

| [74] |

(薛聪, 胡影影, 黄争鸣. 高分子通报, 2009, 6: 38 )

|

| [75] |

|

| [76] |

|

| [77] |

|

| [78] |

|

| [79] |

|

| [80] |

|

| [81] |

|

| [82] |

|

| [83] |

|

| [84] |

|

| [85] |

|

| [86] |

|

| [87] |

|

| [88] |

|

| [89] |

|

| [90] |

|

| [91] |

|

| [92] |

|

| [93] |

|

| [94] |

|

| [95] |

|

| [96] |

|

| [97] |

|

| [98] |

|

| [99] |

|

| [100] |

|

| [101] |

|

| [102] |

|

| [103] |

|

| [104] |

|

| [105] |

|

| [106] |

|

| [107] |

|

| [108] |

|

| [109] |

|

| [110] |

|

| [111] |

|

| [112] |

|

| [113] |

|

| [114] |

|

| [115] |

|

| [116] |

|

| [117] |

|

| [118] |

|

| [119] |

|

| [120] |

|

| [121] |

|

| [122] |

|

| [123] |

|

| [124] |

|

| [125] |

|

| [126] |

|

| [127] |

|

| [128] |

|

| [129] |

|

| [130] |

|

| [131] |

|

| [132] |

|

| [133] |

|

| [134] |

|

| [135] |

|

/

| 〈 |

|

〉 |