Synthesis of 4-Monosubstituted 1,2,3-Triazoles

Received date: 2023-10-30

Revised date: 2024-03-10

Online published: 2024-07-01

Supported by

National Natural Science Foundation of China(21662020)

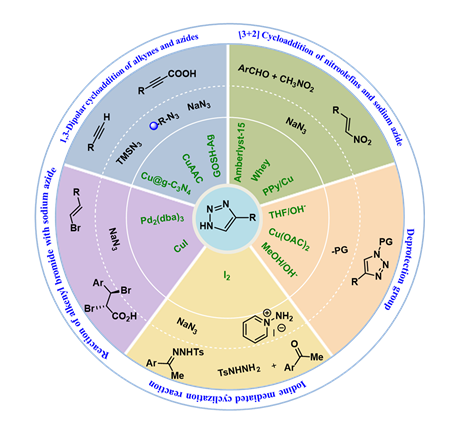

1,2,3-Triazoles are a kind of five-membered N-heterocycles featured with unique properties in biology and material science.They have played more and more important roles in the fields of medicine,pesticide,and materials since the Cu-catalyzed diploar cycloaddition reaction of azide and alkyne was founded by Sharpless and Medal groups,respectively.4-Monosubstituted 1,2,3-triazole is considerably important in its family,especially because of its structural merits of widely facile modifications.The synthesis of 4-monosubstituted 1,2,3-triazoles based on different reaction types and substrates,including cycloaddition of alkyne with azide,cycloaddition of nitroolefin with azide,cyclization of hydrazone with amino derivatives,and N1-substituent removal of 1,4-disubstituted 1,2,3-triazoles are reviewed.The substrate scope,limitation,and representative mechanism are also discussed 。

1 Introduction

2 Progress in the synthesis of 4-monosubstituted 1,2,3-triazoles

2.1 1,3-Dipolar cycloaddition of alkyne and azide

2.2[3+2]Cycloaddition of nitroolefin and azide

2.3 Cyclization of hydrazone with amino derivative

2.4 Removal of N1-substituent from 1,4-disubstituted 1,2,3-triazole

2.5 Reaction of alkenyl bromide with sodium azide

2.6 Other methods

3 Conclusion and outlook

Liguo Teng , Shuitao Zhang , Tiebo Xiao , Baomin Yang , Yubo Jiang . Synthesis of 4-Monosubstituted 1,2,3-Triazoles[J]. Progress in Chemistry, 2024 , 36(7) : 1014 -1025 . DOI: 10.7536/PC231017

| [1] |

(王景梅, 李凌君, 张贵生. 有机化学, 2009, 29(1): 13.).

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

(肖琳霞, 石德清. 有机化学, 2010, 30(1): 85.).

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

(刘家健. 中国抗生素杂志, 2006, 31(2): 100.)

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

(张文生, 匡春香, 杨青. 有机化学, 2011, 31(1): 54.).

|

| [27] |

(江玉波, 殷云川, 陈润奇, 雷鹏飞, 肖付俊. 化学研究与应用, 2014, 26(11): 1695.).

|

| [28] |

(江玉波, 赵粉, 韩春美, 梁雪秋, 杨睿. 化学研究与应用, 2014, 26(12): 1831.).

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

(王亮, 潘亮, 陈群, 何明阳. 常州大学学报(自然科学版), 2017, 29(4): 1.).

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

| [74] |

|

| [75] |

|

| [76] |

|

| [77] |

|

| [78] |

|

/

| 〈 |

|

〉 |