Gamma Ray Shielding Composite Material with High Z Number

Received date: 2023-11-06

Revised date: 2024-03-05

Online published: 2024-05-20

Supported by

Anhui Province Ecological Environment Research Project(2023hb0017)

University Synergy Innovation Program of Anhui Province(GXXT-2022-001)

Comprehensive Research Facility for Fusion Technology Program of China(2018-000052-73-01-001228)

Institute of Energy, Hefei Comprehensive National Science Center(21KZL401)

Institute of Energy, Hefei Comprehensive National Science Center(21KHH105)

Institute of Energy, Hefei Comprehensive National Science Center(21KZS205)

Institute of Energy, Hefei Comprehensive National Science Center(24JYZL01)

Institute of Energy, Hefei Comprehensive National Science Center(24JYJB01)

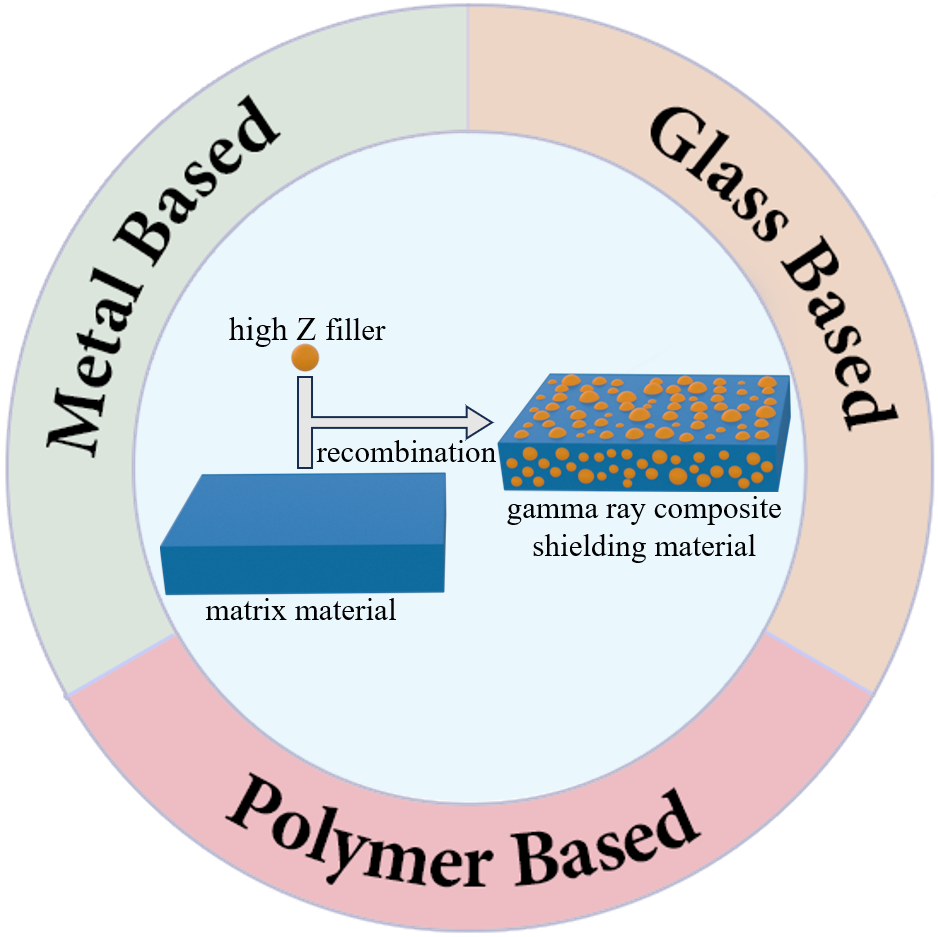

With the development of science and technology,nuclear technology is widely used in energy,medicine,aerospace,and other fields.However,the high-energy gamma ray produced by the application of nuclear technology has strong penetrating ability and can ionize human cells,which will cause damage to human health.Therefore,it is crucial to develop effective radiation shielding materials.Since the density and effective atomic number of materials have great influence on the gamma shielding properties of materials,fillers containing high atomic number(high Z)elements are introduced into various matrix materials by researchers to prepare composite shielding materials.This paper explains Three fundamental physical effects of the interaction between gamma photons and atoms.three kinds of high Z gamma ray composite shielding materials based on glass,polymer,and metal matrixes are introduced respectively,and the existing challenges and solutions are summarized。

1 Introduction

2 Interaction of gamma ray with matter

3 Research progress of gamma ray composite shielding material with high Z number

3.1 Glass-based gamma ray composite shielding materials with high Z number

3.2 Polymer-based gamma ray composite shielding materials with high Z number

3.3 Metal-based gamma ray composite shielding materials with high Z number

4 Conclusion and prospect

Key words: high Z number; radiation shielding; composite material; gamma ray

Zuoyang Chen , Zhipeng Huo , Hong Zhang , Guoqiang Zhong . Gamma Ray Shielding Composite Material with High Z Number[J]. Progress in Chemistry, 2024 , 36(7) : 1102 -1116 . DOI: 10.7536/PC231105

表1 Typical high-Z glass-based gamma ray composite shielding materials and their performance parametersTable 1 Typical glass-based gamma-ray composite shielding materials with high Z number and their performance parameters |

| Chemical composition | Physical property | Gamma energy (MeV) | Shielding performance | Ref |

|---|---|---|---|---|

| 80 mol% TeO2-20 mol% TiO2 | ρ: 5.27, Vm: 27.26 | 0.2 | μ/ρ: 0.28, μ: 1.52, HVL: 0.032 | 20 |

| 54.6 wt% TeO2-22.6 wt% WO3-22.8 wt% Bi2O3 | ρ: 6.381 | 2 | μ/ρ: 0.044, HVL: 2.24 | 25 |

| 54 mol% TeO2-27.6 mol% B2O3-7.9 mol% CaO-10 mol% CaF2- 0.5 mol% Yb2O3 | ρ: 4.46 | 0.347 | μ/ρ: 0.123, μ: 0.551 | 26 |

| 45 mol% B2O3-25 mol% Bi2O3-15 mol% ZnO-15 mol% Na2O | ρ: 7.94, Vm: 16.41 | 2.4 | HVL: 1.98, MFP: 2.51 | 29 |

| 20 mol% B2O3-40 mol% Bi2O3-30 mol% PbO-10 mol% Li2O | ρ: 5.94 | 0.1 | μ/ρ: 4.849, HVL: 0.024 | 30 |

| 36 wt% B2O3-40 wt% PbO-20 wt% ZnO-4 wt% CaMg(CO3)2 | ρ: 3.868 | 0.356 | μ: 0.638, HVL: 1.23 | 31 |

| 30 mol% LiF-10 mol% SrO-59.75 mol% B2O3-0.25 mol% Cr2O3 | ρ: 2.563 | 0.356 | μ/ρ: 0.0971, HVL: 2.75 | 34 |

| 40 mol % B2O3-30 mol % Na2O-20 mol %ZnO-10 mol %WO3 | ρ: 3.01, Vm: 28.45 | 0.2 | μ: 0.84, HVL: 0.853, MFP: 1.23 | 35 |

| 20 mol% B2O3-10 mol% ZnO-10 mol% MgO-60 mol% Bi2O3 | ρ: 7.107 | 0.3 | μ/ρ: 0.344, HVL: 0.52 | 36 |

| 20 mol% CaO-10 mol% K2O-20 mol% Na2O-50 mol% P2O5 | ρ: 2.2251 | 0.661 | μ/ρ: 0.075 | 40 |

| 38 mol% P2O5-20 mol% B2O3-5 mol% Al2O3-25 mol% Na2O-12 mol% CoO | ρ: 2.785 | 0.356 | μ/ρ: 0.1, HVL: 2.51 | 43 |

| 35 mol% P2O5-50 mol% BaO-15 mol% WO3 | ρ: 4.45, Vm: 36.2 | 0.2 | μ: 1.81, μ/ρ: 0.34, HVL: 0.45 | 45 |

Parameter:ρ:density(g/cm3);Vm:molar volume(cm3mol-1);μ/ρ:mass attenuation coefficient(cm2/g);μ:linear attenuation coefficients(cm-1);HVL:half value layer(cm);MFP:mean free path(cm )。 |

表2 Typical High-Z Polymer-based Gamma Ray Composite Shielding Material and Its Performance ParametersTable 2 Typical polymer-based gamma-ray composite shielding materials with high Z number and their performance parameters |

| Chemical composition | Mechanical property | Gamma energy (MeV) | Shielding performance | Ref |

|---|---|---|---|---|

| 57.8 wt% Bi2O3/NR | σb: 20.13, δ: 640 | 0.662 | μ/ρ: 0.118, HVL: 3.67 | 55 |

| 65 wt% Bi4Ti3O12/ER | Hs: 84.01 | 0.1 | μ/ρ: 5.4 | 58 |

| 10 wt% W/10 wt% BNNS/LDPE | σe: 0.68, σs: 8.5 | 0.662 | μ: 0.082, μ/ρ: 0.083 | 59 |

| 50 wt% Sm2O3/UHMWPE | σb: 20.0, δ: 117 | 0.334 | μ/ρ: 0.149, HVL: 2.726 | 64 |

| 21 wt% Sm2O3/16.5 wt% acetone/62.5 wt% PI | σb: 200, σe: 24 | 0.662 | Sγ: 42.4(THK: 50) | 66 |

| 1.7 wt% DyB2O2/LDPE | σy: 203.7, σb: 12.3, δ: 82.7 | 0.1 | μ: 10.45, μ/ρ: 1.15 | 71 |

| 30 wt% HOFA/ER | σy: 1940 | 0.11 | μ: 0.204, HVL: 3.37 | 74 |

| 14 wt% Bi2O3/DGEBA | σb: 326, δ: 1.8 | 0.356 | μ/ρ: 0.15 | 75 |

| 40 wt% PWO@SMA/PVA | σb: 3.4 | 0.105 | Sγ: 31.13(THK: 2) | 76 |

| 60 wt% WO3/SR | σy: 3.41, σb: 4.295 | 0.06 | μ: 3.9, μ/ρ: 1.68 | 78 |

Parameter:σy:young's modulus(GPa);σb:tensile strength(MPa);δ:elongation at break(%);Hs:shore hardness(HD);σe:elastic modulus(GPa);σs:yield strength(MPa);THK:thickness of sample(cm);Sγ:gamma shielding rate(%);Sn:neutron shielding rate(%);μ/ρ:mass attenuation coefficient(cm2/g);μ:linear attenuation coefficients(cm-1);HVL:half value layer(cm )。 |

表3 Typical high-Z metal-based gamma ray composite shielding materials and their performance parametersTable 3 Typical metal-based composite shielding materials with high Z number and their performance parameters |

| Chemical composition | Physical property | Gamma energy (MeV) | Shielding Performance | ref |

|---|---|---|---|---|

| 85 wt%W/15 wt%Cu | ρ: 16.37 | 0.276 | Sγ: 54.7(THK: 2.7) | 91 |

| 2.4 wt% B4C/NiCoFeCrW | σb: 1740, Hv: 474 | 0.4 | MFP: 0.52 | 100 |

| 60Pb/20Sn/10Zn/10Cd (mol%) | ρ: 9.781 | 0.662 | μ/ρ: 0.101 | 104 |

| 50 wt%Bi/40 wt%Sn/10 wt%Zn | ρ: 8.649 | 0.662 | μ/ρ: 0.0938, μ: 0.8113 | 105 |

| Fe0.95Se0.5Te0.5 | ρ: 5.7971 | 0.662 | μ/ρ: 0.07527 | 106 |

Parameter:σb:tensile stress(MPa);Hν:vickers hardness(HV);ρ:density(g/cm3);THK:thickness of sample(mm);μ:linear attenuation coefficients(cm-1);μ/ρ:mass attenuation coefficient(cm2/g);HVL:half value layer(cm);MFP:mean free path(cm);Sγ:gamma shielding rate(% )。 |

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

(程吉贵. 广西大学博士论文, 2023.).

|

| [18] |

(贾夏冰. 西南科技大学硕士论文, 2016.).

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

| [74] |

|

| [75] |

|

| [76] |

|

| [77] |

|

| [78] |

|

| [79] |

|

| [80] |

|

| [81] |

|

| [82] |

|

| [83] |

|

| [84] |

|

| [85] |

|

| [86] |

|

| [87] |

|

| [88] |

|

| [89] |

|

| [90] |

|

| [91] |

|

| [92] |

|

| [93] |

|

| [94] |

|

| [95] |

|

| [96] |

|

| [97] |

|

| [98] |

|

| [99] |

|

| [100] |

|

| [101] |

|

| [102] |

|

| [103] |

|

| [104] |

|

| [105] |

|

| [106] |

|

/

| 〈 |

|

〉 |