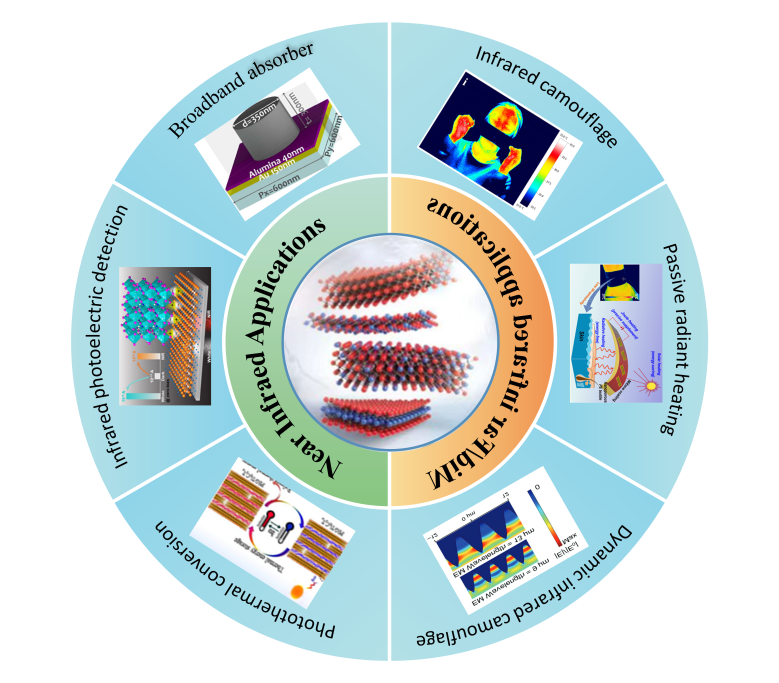

Research Progress and Challenges in Infrared Applications of MXene Materials

Received date: 2024-01-23

Revised date: 2024-04-06

Online published: 2024-07-01

Supported by

National Natural Science Foundation of China(52173191)

MXene is a two-dimensional transition metal carbon/nitrogen compound or carbon-nitrogen compound obtained from MAX phase materials by chemical etching followed by ultrasonic or intercalation treatment.It has the properties of two-dimensional atomic layer structure,abundant components,metallic conductivity,large specific surface area and active surface,etc.It has distinct infrared absorption in the near-infrared and mid\far-infrared bands,and has attracted extensive attention from researchers in recent years in a number of infrared applications,such as infrared camouflage,photothermal conversion,and photovoltaic effect.in this paper,the properties of MXene materials in the infrared band are reviewed in detail,including the high absorbance and localized surface plasmon resonance effect in the near-infrared band and the infrared low-emission properties in the mid/far-infrared band.Further based on its infrared properties,the research progress of its applications in popular fields such as infrared camouflage,broadband absorber,passive radiant heating,photothermal conversion and photovoltaic effect is summarized.Finally,the main problems of the current research on MXene materials in the infrared field and the future development direction are prospected。

1 Introduction

2 Infrared properties of MXene

2.1 Near-infrared optical properties

2.2 Middle/far infrared optical properties

3 Research on infrared application of MXene

3.1 Broadband absorber

3.2 Infrared camouflage

3.3 Photothermal conversion

3.4 Passive radiation heating

3.5 Infrared photoelectric detection

4 Conclusion and outlook

Yubin Li , Guoliang Dai , Jie Fan , Hong Xiao . Research Progress and Challenges in Infrared Applications of MXene Materials[J]. Progress in Chemistry, 2024 , 36(9) : 1336 -1348 . DOI: 10.7536/PC240120

图3 Ti3C2Tx MXene的近红外和中远红外光学性质:(a)椭圆形Ti3C2TxMXene 耦合的模拟吸收光谱和LSPR的电场强度图[43];(b)MXene 纳米片的计算吸收光谱[44];(c)MXene的可见光\近红外高吸收率、低红外发射率示意图;(d)真空抽滤Ti3C2TxMXene膜的介电常数实部(ε1)和虚部(ε2)(负的 ε1 值表示金属响应);(e)MXene膜的红外吸收光谱[22];(f)MXene、GO、石墨烯、不锈钢薄膜和MMT在508 ℃热源上的红外图像[46]Fig. 3 NIR and mid- and far-infrared optical properties of Ti3C2Tx MXene, (a) Simulated absorption spectra of elliptical Ti3C2Tx MXene couplings and electric field intensity maps of LSPR[43]; (b) Calculated absorption spectra of MXene nanosheets [44] (Copyright 2021, Royal Society of Chemistry); (c) Schematic diagram of visible/near-infrared high absorptivity, low infrared emissivity of MXene; (d) Vacuum pumped Ti3C2Tx MXene film with real (ε1) and imaginary (ε2) parts of the dielectric constant (negative ε1 values indicate metal response); (e) infrared absorption spectra of the MXene film [22] (Copyright 2023, Springer); (f) infrared images of MXene, GO, graphene, stainless steel film, and MMT on a heat source of 508 ℃[46](Copyright 2021, Wiley) |

| MAX Phase | MXene | visible image | infrared emissivity | ||

|---|---|---|---|---|---|

| 0.76~1.2 μm | 3~5 μm | 8~14 μm | |||

| Ti2AlC | Ti2CTX |  | 0.86 | 0.35 | 0.20 |

| Nb2AlC | Nb2CTX |  | 0.74 | 0.62 | 0.57 |

| V2AlC | V2CTX |  | 0.72 | 0.37 | 0.29 |

| Ti0.4Nb1.6AlC | Ti0.4Nb1.6CTX |  | 0.67 | 0.53 | 0.50 |

| Ti1.6Nb0.4AlC | Ti1.6Nb0.4CTX |  | 0.79 | 0.42 | 0.25 |

| Ti3AlC2 | Ti3C2TX |  | 0.62 | 0.10 | 0.06 |

| Ti3AlCN | Ti3CNTX |  | 0.61 | 0.21 | 0.13 |

| Nb4AlC3 | Nb4C3TX |  | 0.87 | 0.65 | 0.47 |

| V4AlC3 | V4C3TX |  | 0.75 | 0.40 | 0.24 |

| Mo2Ti2AlC3 | Mo2Ti2C3TX |  | 0.57 | 0.42 | 0.31 |

表2 Infrared emissivity of MXene and common two-dimensional nanomaterials (background temperature 510.9 ℃)[46]Table 2 Infrared emissivity of MXene and common 2D nanomaterials(background temperature 510.9℃)[46] |

| material | visible image | Thicknesses/μm | Tr/℃ | Tdecrese/℃ | emissivity/7~14 μm | |

|---|---|---|---|---|---|---|

| MXene |  | 45 | 181 | 319.9 | 0.19 | |

| Graphene |  | 45 | 223 | 287.9 | 0.33 | |

| GO |  | 10 | 294 | 216.9 | 0.65 | |

| MMT |  | 35 | 421 | 89.9 | 0.88 | |

| Stainless steel |  | 30 | 159 | 351.9 | 0.14 | |

图4 (a)MXene超表面吸收器示意图;(b)MXene超表面吸收器面板三维图;(c)MXene超表面吸收器近红外吸收率[56] ;(d)MXene超材料吸收器三维示意图;(e)吸收器垂直截面电场图(λ~ 1.85 μm);(f)MXene及不同衬底材料模拟吸收光谱[57]Fig. 4 (a) Schematic diagram of MXene supersurface absorber; (b) 3D view of MXene supersurface absorber panel; (c) NIR absorptivity of MXene supersurface absorber [56] (Copyright 2023, Elsevier Science); (d) 3D schematic diagram of MXene metamaterial absorber; (e) Electric field map of vertical cross section of absorber (λ~ 1.85 μm); (f) Simulated absorption spectra of MXene and different substrate materials[57] (Copyright 2018, American Chemical Society) |

图5 (a)MXene制备及抽滤成膜示意图[72];(b、c)真空抽滤MXene薄膜飞机模型和手掌的红外伪装热成像图[22];(d)涂层制备MXene膜示意图;(e)涂层制备MXene膜照片;(f、g)12.2 μm涂层制备MXene膜在手掌与人面部的红外热成像图[65];(h)三明治状复合材料结构图;(i)三明治状复合材料横向红外热成像图[72];(j)头足类动物皮肤信号变化概念图;(k)MXene 机器人皮肤随应变变化示意图;(l)MXene机器人皮肤模拟电场分布图[76]Fig. 5 (a) Schematic diagram of MXene preparation and filtration into film[72] (Copyright 2023, Wiley); (b, c) Infrared camouflage thermography of vacuum-filtered MXene film airplane model and palm [22] (Copyright 2023, Springer); (d) Schematic diagram of coating-prepared MXene film; (e) Photographs of the coating-prepared MXene film; (f, g) Infrared thermography of the 12.2 μm coating-prepared MXene film in the palm of the hand and human face[65] (Copyright 2023, Elsevier); (h) structural diagram of sandwich-like composite; (i) transverse infrared thermography of sandwich-like composite [72] (Copyright 2023, Wiley); (j) conceptual diagram of cephalopod skin signal variation; (k) schematic diagram of MXene robot skin variation with strain; (l) simulated electric field distribution of MXene robot skin [76] (Copyright 2022, Wiley) |

图6 (a) MXene/PEG复合材料的光热转换和热储能示意图[88];(b)基于二维 Nb2C MXene近红外-Ⅱ光热疗法的多功能纳米平台[91]Fig. 6 (a) Schematic diagram of photothermal conversion and thermal energy storage of MXene/PEG composites[88] (Copyright 2016, Royal Society of Chemistry); (b) Multifunctional nanoplatform based on two-dimensional Nb2C MXene near infrared-Ⅱ photothermal therapy[91] (Copyright 2021, Royal Society of Chemistry) |

图7 (a)Ti3C2Tx MXene与PU/PET织物的制备示意图;(b)覆盖不同织物的人造皮肤实时温度[105];(c)MXene与纳米PE纺织品的制备示意图及被动辐射加热原理;(d)覆盖不同织物的人造皮肤实时温度(室内环境、27 ± 0.5 ℃)[109]Fig. 7 (a) Schematic of the preparation of Ti3C2Tx MXene with PU/PET fabrics; (b) Real-time temperature of artificial skin covering different fabrics [105] (Copyright 2023, American Chemical Society); (c) Schematic of the preparation of MXene with nano-PE textiles and the principle of passive radiant heating; (d) Real-time temperature of artificial skin covering different fabrics (indoor environment, 27 ± 0.5 ℃) [109] (Copyright 2021, American Chemical Society) |

图8 (a)MAPbI3/Nb2CTx 界面外电荷转移和SP示意图;(b)器件在532 nm LED照明下的上升和衰减时间;(c)器件在1064 nm 激光强度下电流;(d)与时间相关的电流显示上升和衰减时间[118];(e)异质结构Ti3C2Tx-RAN 近红外光电探测器结构示意图;(f)Au-RAN PD 和 Ti3C2Tx-RAN PD的通断比比较[119]Fig. 8 (a) Schematic of charge transfer and SP outside the MAPbI3/Nb2CTx interface; (b) Rise and decay times of the device under the illumination of a 532 nm LED; (c) Device current at 1064 nm laser intensity; (d) Temporal dependent current to show the rise and decay time [118] (Copyright 2022, American Chemical Society) (e) Schematic of the structure of the heterostructured Ti3C2Tx-RAN near-infrared photodetector; (f) Comparison of the on/off ratios of the Au-RAN PDs and Ti3C2Tx-RAN PDs [119] (Copyright 2022, Wiley) |

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

| [74] |

|

| [75] |

|

| [76] |

|

| [77] |

|

| [78] |

|

| [79] |

|

| [80] |

|

| [81] |

|

| [82] |

|

| [83] |

|

| [84] |

|

| [85] |

|

| [86] |

|

| [87] |

|

| [88] |

|

| [89] |

|

| [90] |

|

| [91] |

|

| [92] |

|

| [93] |

|

| [94] |

|

| [95] |

|

| [96] |

|

| [97] |

|

| [98] |

|

| [99] |

|

| [100] |

|

| [101] |

|

| [102] |

|

| [103] |

|

| [104] |

|

| [105] |

|

| [106] |

|

| [107] |

|

| [108] |

|

| [109] |

|

| [110] |

|

| [111] |

|

| [112] |

|

| [113] |

|

| [114] |

|

| [115] |

|

| [116] |

|

| [117] |

|

| [118] |

|

| [119] |

|

/

| 〈 |

|

〉 |