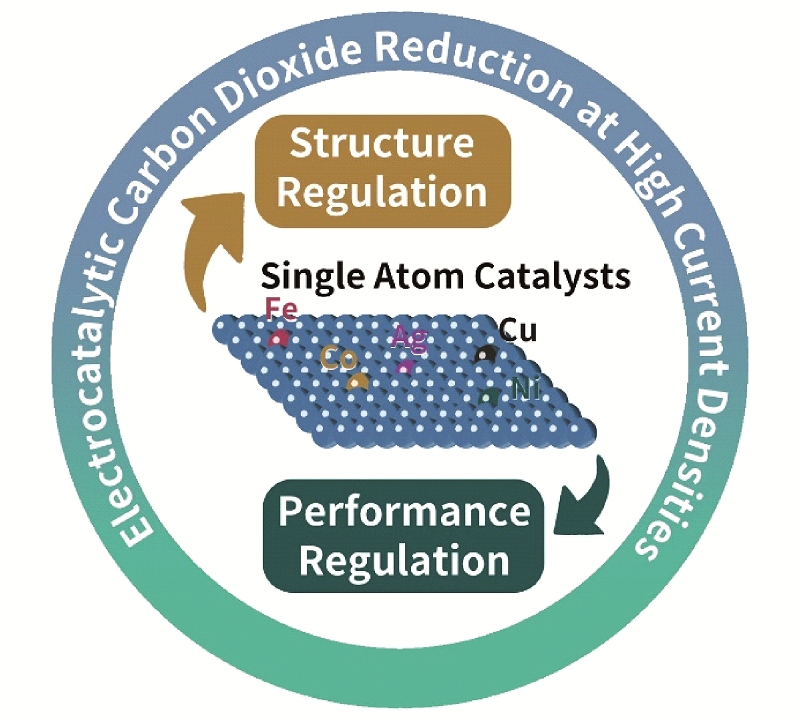

Single-Atom Catalysts for Electrocatalytic Carbon Dioxide Reduction at High Current Densities

Received date: 2022-11-07

Revised date: 2023-01-10

Online published: 2023-02-15

Supported by

National Natural Science Foundation of China(22108306)

Taishan Scholars Research Project(tsqn201909065)

Excellent Youth Science Foundation of Shandong Province(ZR2021YQ15)

Shandong Provincial Natural Science Foundation, China(ZR2020QB174)

Electrocatalytic carbon dioxide reduction (ECR) is an environmentally friendly energy conversion method that can convert CO2 into various high value-added fuels or chemicals. However, it usually is subject to low catalytic activity, low selectivity and low macrocyclic stability at high current densities. Benefitting from the advantages of high selectivity, high catalytic activity and high atom utilization, single atom catalysts show great potential in ECR process. Therefore, how to design single atom catalysts with high activity, high selectivity and high macrocyclic stability has become a research hot issue in this field. This paper reviews the research progress of a series of single atom catalysts in electrocatalytic carbon dioxide reduction at high current densities, and focuses on the activity regulation mechanisms, product selectivity regulation mechanisms and macrocyclic stability regulation mechanisms to enhance the ECR performance of single atom catalysts, which provides ideas for the systematic design and synthesis of ECR single atom catalysts. The opportunities and challenges of ECR single atom catalysts are prospected.

Jiaye Li , Peng Zhang , Yuan Pan . Single-Atom Catalysts for Electrocatalytic Carbon Dioxide Reduction at High Current Densities[J]. Progress in Chemistry, 2023 , 35(4) : 643 -654 . DOI: 10.7536/PC221103

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

/

| 〈 |

|

〉 |