Study and Applications of Two-Dimensional Nanochannel Ion Sieving Membranes

Received date: 2024-08-19

Revised date: 2025-01-08

Online published: 2025-03-20

Supported by

Foundation Research Project of Kaili University(2025ZD007)

National Natural Science Foundation of China(U21A20302)

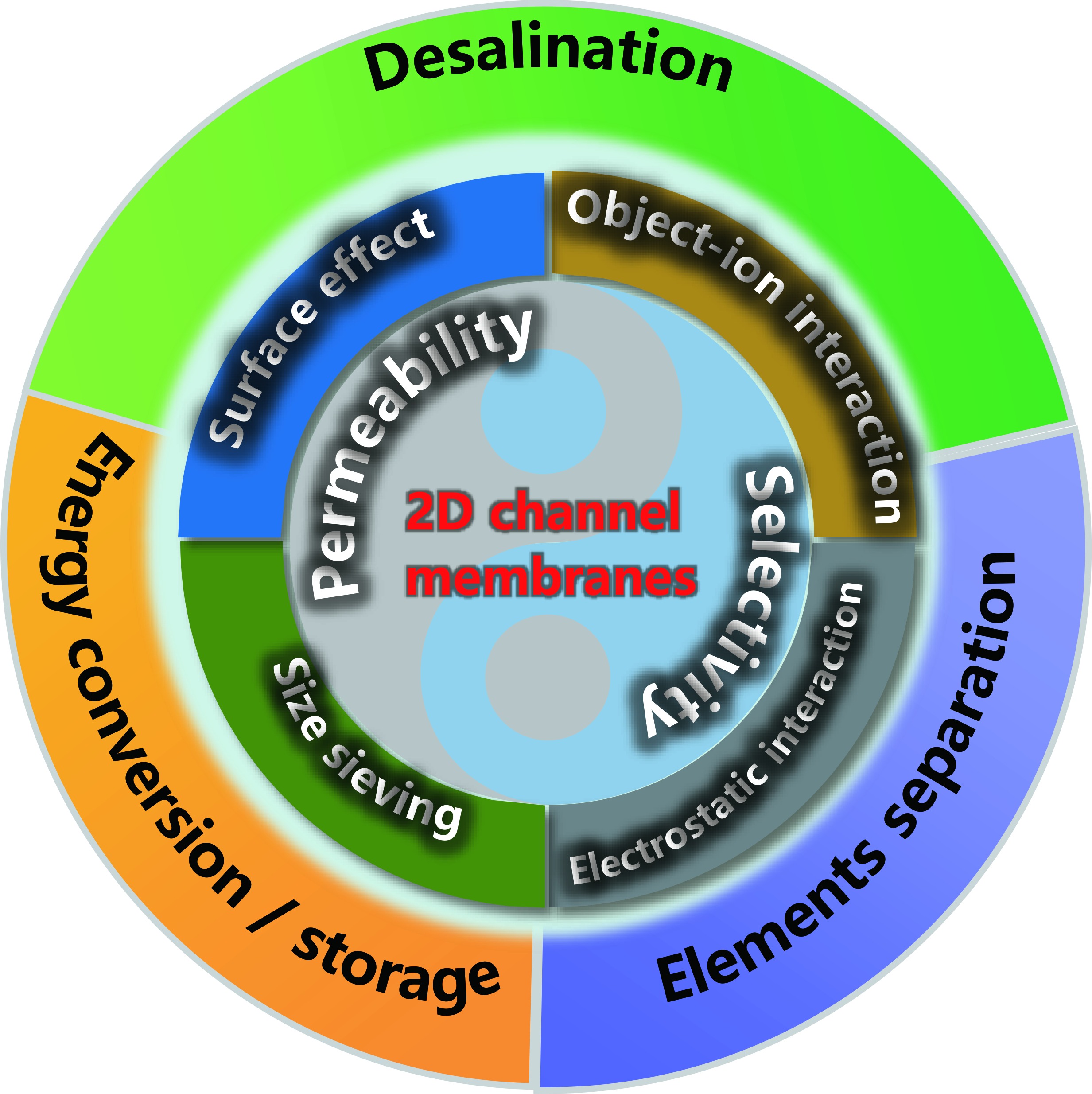

Two-dimensional nanochannel membrane is a new membrane composed of two-dimensional nanosheets with atomic layer thickness and stacked by self-assembly. Compared with traditional separation membranes,its ion separation behavior has many unique characteristics,and has important potential applications in seawater desalination,energy storage and conversion,rare element extraction and separation,and other fields. These materials have attracted great interest and wide attention from researchers. It has become an important development direction and research hotspot in the field of membrane separation science and technology in recent years. In this paper,the construction strategy,performance evaluation method and mass transfer mechanism of two-dimensional nanochannel membranes were systematically summarized from the perspective of two-dimensional nanochannel membranes used for accurate ion sieving. The latest research progress in the preparation and application of two-dimensional nanochannel membranes in recent years was reviewed,and the development trend was prospected. We hope this review can provide enlightenment for structure design and optimization,performance enhancement,large-scale preparation and engineering applications of two-dimensional nanochannel membranes in the future.

1 Introduction

2 Two-dimensional nanochannel ion sieving membrane and its construction methods

2.1 Two-dimensional nanochannel ion screening membrane

2.2 Construction method of 2D nanochannel ion sieving membrane

2.3 Characterization of structure and evaluation of properties of two-dimensional nanochannel ion sieving membranes

3 Mass transfer mechanism in two-dimensional nanochannels

3.1 Mass transfer mechanism of solvent in two-dimensional channels

3.2 Mass transfer mechanism of ions in two-dimensional channels

4 Application of two-dimensional nanochannel ion sieving membrane

4.1 Desalination of seawater

4.2 Energy conversion and storage

4.3 Extraction and separation of elements

5 Conclusion and outlook

Jianyu Wang , Shuai Wang , Chuanjie Fang , Baoku Zhu , Liping Zhu . Study and Applications of Two-Dimensional Nanochannel Ion Sieving Membranes[J]. Progress in Chemistry, 2025 , 37(4) : 564 -574 . DOI: 10.7536/PC240802

图1 二维通道的结构及传质过程(以氧化石墨烯GO为例)。(a)GO膜的断层结构SEM图;(b,c)GO膜的传质示意图[13]Fig.1 Structure and mass transfer process of two-dimensional channel (take GO as an example). (a) Cross-section structure diagram of GO membrane under SEM;(b,c) Mass transfer diagram of GO membrane[13]. Copyright 2012,American Chemical Society |

图2 二维纳米通道膜的主要制备方法。(a)真空辅助过滤法;(b)旋涂法[22];(c)刮涂法[20];(d)电泳法[21]Fig.2 Main preparation methods of two-dimensional nanochannel films. (a) Vacuum assisted filtration;(b) spin coating[22],Cpyright 2020,Elsevier;(c) scraping coating[20],Copyriht 2023,Wiley;(d) electrophoretic method[21],Copyrigtht 2022,Elsevier |

图3 二维纳米片及二维通道膜的表征。MXene纳米片的(a)AFM图和(b)TEM图[25];GO二维纳米通道膜的SEM(c)表面和(d)断层图[26]Fig.3 Characterization of two-dimensional nanosheets and two-dimensional channel membranes. (a) AFM diagram and (b) TEM diagram of MXene nanosheets[25];Copyright 2023,Wiley. SEM (c) surface and (d) tomography of GO 2D nanochannel membrane[26]. Copyright 2024,Elsevier |

图4 二维纳米通道膜的性能评估方法。(a)正渗透装置示意图[27];(b)反渗透死端过滤装置示意图;(c)反渗透错流装置示意图[23]Fig.4 Performance evaluation method of two-dimensional nanochannel membrane. (a) Schematic diagram of the forward osmosis device[27];Copyright 2024,Springer Nature. (b) Schematic diagram of reverse osmosis dead-end filter device. (c) Schematic diagram of reverse osmosis cross-flow device[23]. Copyright 2022,Elsevier |

图6 二维纳米通道膜的应用。(a)GO膜用于多级过滤海水淡化[56];(b)MXene膜用于盐差能转化[67];(c)GO膜用于核素筛分Fig.6 Application of two-dimensional nanochannel membranes. (a) GO membrane is used for multistage filtration of seawater desalination[56];Copyright 2023,American Chemical Society. (b) MXene membrane for salt difference energy conversion[67];Copyright 2023,Wiley. (c) GO membrane for the screening of nuclides. Copyright 2022,Springer Nature |

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

Van der Bruggen B,

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

(王奉超, 朱银波, 吴恒安. 中国科学: 物理学力学天文学, 2018, 48(9): 117.).

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

van der Vegt N F A,

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

/

| 〈 |

|

〉 |