Post-Combustion CO2 Capture Materials

†These authors contributed equally to this work.

Received date: 2024-06-21

Revised date: 2024-10-10

Online published: 2025-03-20

Supported by

Youth Funding Project of the "Young Thousand Talents Program" of the Organization Department of the CPC Central Committee(40127002)

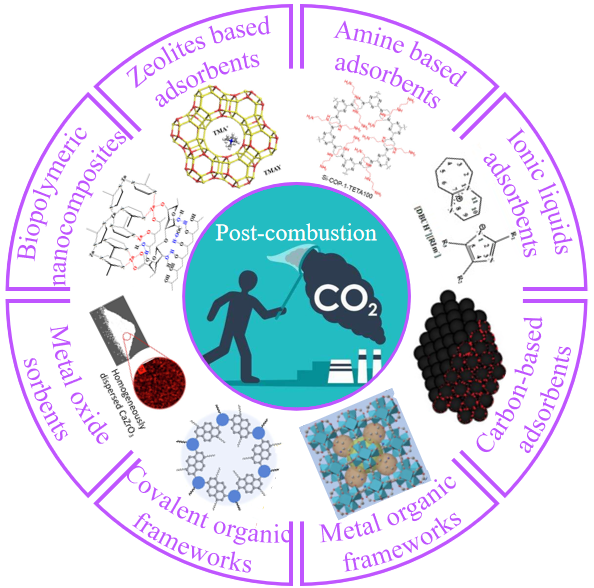

The sustained development of industry has brought enormous economic benefits,but it has also caused great harm to the environment. The excessive CO2 emissions from fossil fuel combustion are released into the natural environment,posing a threat to the environment and human health. So people are working hard to develop materials that can effectively capture CO2. At present,CO2 capture mainly occurs after the combustion of fossil fuels. According to the design standards for CO2 adsorbents,a variety of CO2 capture materials have been designed and developed,including solid adsorbents,liquid adsorbents,and multiphase adsorbents. The adsorption mechanisms of various adsorbents are also different,including adsorption,absorption,or a combination of both mechanisms. This review focuses on the capture performance,absorption mechanism,advantages and disadvantages of various common types of current adsorbents,and introduces amine solution absorbents,zeolite-based adsorbents,ionic liquids-based adsorbents,carbon-based adsorbents,metal-organic framework materials,covalent organic framework materials,metal-oxide materials,and biopolymer nanocomposites,respectively,with an outlook of the future development of CO2 adsorbent materials.

Contents

1 Introduction

1.1 Current status and hazards of CO2 emissions

1.2 CO2 capture technology

1.3 Criteria for designing CO2 capture materials

2 CO2 capture materials

2.1 Amine solution absorbents

2.2 Zeolites based adsorbents

2.3 Ionic liquids absorbents

2.4 Carbon-based adsorbents

2.5 Metal organic framworks

2.6 Covalent organic frameworks

2.7 Metal oxide sorbents

2.8 Biopolymeric nanocomposites

3 Comparison and Prospect of Capture Materials

4 Conclusion

Jiajia Jiang , Junhu Zhao , Qin Yu , Tian Zhang . Post-Combustion CO2 Capture Materials[J]. Progress in Chemistry, 2025 , 37(4) : 593 -611 . DOI: 10.7536/PC240608

表1 三种碳捕获技术的比较Table 1 Comparison of three carbon capture technologies |

| CO2 capture technology | Advantages | Disadvantages |

|---|---|---|

| Pre-combustion capture | The concentration of CO2 is high which makes it easy to capture | Not applicable to existing power plants;high investment cost;a large amount of energy consumed for chemical solvent regeneration |

| Oxy-fuel capture | The concentration of CO2 is high which makes it easy to capture;avoids the requirement of chemicals | A large amount of pure oxygen needs to be provided;high investment cost;limited existing technical knowledge |

| Post-combustion capture | Suitable for large new and existing power plants,without the need for upgrades and renovations;convenient maintenance | High energy consumption of adsorbent regeneration;low CO2 concentration in flue gas |

表2 部分沸石对于CO2捕获性能Table 2 CO2 capture performance of some zeolites |

| Zeolites | BET (m2/g) | Temperature (K) | Pore size (nm) | Capacity (mmol/g) | CO2/N2 selectivity | Qst (kJ/mol) | Ref |

|---|---|---|---|---|---|---|---|

| SAPO-34 | 402.2 | 278 | 0.3~0.8 | 22.7 | 2.6 | 36.74 | 33 |

| Z4A | 39 | 273 | 4.7 | 3.77 | / | 32.45 | 34 |

| HZ4A-1-3 | 126 | 273 | 5.5 | 3.41 | / | 28.02 | 34 |

| CS-ZX | 561 | 298 | / | 4.23 | / | 10.4 | 35 |

| 3D-LTA | 9.00 | 273 | 4 | 1.99 | / | 21.49 | 36 |

| 2D-LTA | 12.66 | 273 | 4 | 2.31 | / | 44.52 | 36 |

| Co(II)/SSZ-13 | 786.75 | 273 | / | 4.49 | 52.55 | / | 26 |

| Ni(II)/SSZ-13 | 836.01 | 273 | / | 4.45 | 42.61 | / | 26 |

| NZL-500 | 670.11 | 298 | / | 5.56 | 619.99 | / | 37 |

| N-L | 427.2 | 298 | / | 2.85 | 198.6 | / | 38 |

| Modified Z-13X | 16.58 | 298 | 1.2 | 5.50 | / | 40.681 | 39 |

| KX | 720.14 | 298 | 1.944 | 4.90 | 152 | / | 40 |

| MCM41-450 | 259.10 | 298 | / | 2.275 | / | / | 41 |

| Na-ZK-4 | 687 | 273 | / | 4.86 | 49 | 40~45 | 42 |

| Li-LSX | 662.00 | 273 | 0.8~1.8 | 4.21 | 85.7 | / | 43 |

| ZSM-5-25 | 404 | 273 | 0.5 | 2.22 | 77~149 | / | 44 |

| HASM-5 | 417.63 | 298 | 2.647 | 4.27 | / | 54.27 | 45 |

| Calcined Beads@2.0-3.0mm | 586 | 273 | 5.4 | 4.5 | / | / | 46 |

| Zeolite X | 735.88 | 273(303) | 0.6 | 7.3(6.1) | / | / | 47 |

表3 不同前驱体合成碳材料对于CO2捕获性能Table 3 CO2 capture performance of synthesized carbon materials with different precursors |

| Different precursors | Exemple | BET (m2/g) | Temperature (K) | Pressure (bar) | Capacity (mmol/g) | Qst (kJ/mol) | Ref |

|---|---|---|---|---|---|---|---|

| Biomass-derived porous carbons | ANKO1 | 1894 | 273(298) | 1 | 7.18(4.81) | / | 63 |

| SWC-derived AC | 1085 | 298 | 1 | 2.63 | 14 | 64 | |

| ACPS600-K-4 | 2437 | 273 | 1 | 5.79 | / | 65 | |

| Synthetic resin-derived porous carbons | NSOPC-1 | 1292 | 273(298) | 1 | 7.04(3.88) | / | 66 |

| UFC-600-3 | 1686 | 273(298) | 1 | 5.42(3.53) | 45 | 67 | |

| PPSC-650-2 | 1094 | 273(298) | 1 | 3.64(5.13) | 35~41 | 68 | |

| Synthetic polymer-derived porous carbons | KOH-700 | 2155 | 273 | 1 | 6.23 | 26.5~29.2 | 69 |

| K2CO3-800 | 1143 | 273 | 1 | 5.47 | 37.1 | 69 | |

| 3DOmm | 1462 | 273(298) | 1 (20) | 3.19(11.18) | 18.9~29.2 | 57 | |

| Biopolymer-derived porous carbons | LBAU5 | 1134 | 273 | / | 4.06 | / | 70 |

| LHPC-700 | 1788 | 273(298) | 1 | 8.2(4.8) | 28.6 | 71 | |

| CHNH1∶2 | 2906 | 273 | 1 | 7.38 | 46.87 | 72 | |

| Graphene-derived porous carbons | CuBTC/GO | 1760 | 273(298) | 1 | 9.59(5.33) | 25.3~25.6 | 73 |

| a-RGO-950 | 1316 | 273 | 1 | 3.36 | 27.42 | 74 | |

| T-GU-700-6 | 1032 | 273(298) | 1 | 3.24(2.40) | 12~33 | 75 | |

| Fossil resources-derived porous carbons | IANC | 2186 | 298 | 1 (35) | 7.15(29.29) | / | 76 |

| A-rNPC | 2580 | 296 | 30 | 26.0 | 29.0 | 77 | |

| ARA | 1590 | 298 | 4 | 7.56 | 23.0 | 78 |

表4 部分MOFs对于CO2捕获性能Table 4 Performance of some MOFs for CO2 capture |

| MOFs | BET (m2/g) | Temperature (K) | Pressure (bar) | Capacity (mmol/g) | CO2/N2 selectivity | Qst (kJ/mol) | Ref |

|---|---|---|---|---|---|---|---|

| Co-3-OADA | / | 273 | 1 | 2.02 | 48 | 34 | 89 |

| Zn-3-OADA | / | 273 | 1 | 1.91 | 43 | 25 | 89 |

| UTSA-16(Zn) | 786.61 | 298 | 1 | 4.71 | 118 | / | 90 |

| UTSA-16(Zn,Mn) | 810.43 | 298(333) | 1 | 5.28(3.76) | 135(95) | / | 83 |

| UTSA-16(Zn,Mg) | 825.19 | 298(333) | 1 | 5.56(3.95) | 141(97) | / | 83 |

| UTSA-16(Zn,Cu) | 817.40 | 298(333) | 1 | 5.13(3.60) | 131(92) | / | 83 |

| PAN/MIL-101 | 2657.7 | 343.96 | 1 | 2.48 | 38 | 31.88 | 91 |

| NBC@MOF-99 | 553.4 | 298~303 | 1 | 2.9 | / | / | 92 |

| MOF-74(Ni) | 1129 | 273(298) | 1 | 8.29(6.61) | 49 | 27~52 | 93 |

| Cu-OATA | / | 273(298) | 1 | 5.61(2.02) | 43.8 | 25 | 94 |

| CUT | 802 | 273 | 1 | 2.53 | 34.2 | 30.15 | 95 |

| Zr-MOF-808/NH2 | 2021 | 298 | 9 | 8.39 | / | 17.36 | 96 |

| Ni(3-ain)2 | 790.1 | 298 | 1 | 3.73 | 26.3 | 31.8 | 97 |

| CuBDC-NO2 | 523 | 298 | 1 | 2.40 | 28 | 20.2 | 98 |

| MC-HUN-4 | 523 | 298 | 1 | 1.90 | 13.02 | / | 99 |

| NaX | 17.39 | 273 | 1.13 | 4.34 | 89.2 | 37.9 | 100 |

| NUM-3a | 2111.2 | 273(298) | 1 | 4.56(3.35) | 82.8(64.8) | / | 101 |

图16 (a) 1,3,6,8-四(4-氰苯)芘构建CTFs结构示意图[107],(b)微孔ICTF-Cl、ICTF-SCN和ICTF-Cl- SCN合成示意图,(c) COF (Me3TFB-(NH2)2BD)合成与CO2捕集示意图[111]Fig.16 (a) Schematic diagram of CTFs constructed from 1,3,6,8-tetrakis(4-cyanobenzene)pyrene[107],(b) Schematic diagram of the synthesis of microporous ICTF-Cl,ICTF-SCN,and ICTF-Cl- SCN,(c) Schematic of the synthesis of COF (Me3TFB-(NH2)2BD) and CO2 capture by COF[111] |

表5 部分COFs对于CO2捕获性能Table 5 Performance of some COFs for CO2 capture |

| COFs | BET (m2/g) | Temperature (K) | Pore size (nm) | Capacity (mmol/g) | CO2/N2 selectivity | Qst (kJ/mol) | Ref |

|---|---|---|---|---|---|---|---|

| JUC-610 | 2072 | 273(298) | 1.5 | 2.26(1.44) | / | 21.9 | 112 |

| Cu-anPPCs | 2043 | 273(298) | 0.5 | 7.6 | / | 40.6 | 113 |

| UPC-6Li | 5974.80 | 298 | 16.37 | 8.95 | 308 | 38.75 | 114 |

| UPC-6Na | 5608.74 | 298 | 17.31 | 7.60 | 235 | 34.82 | 114 |

| UPC-6K | 3759.12 | 298 | 14.67 | 5.67 | 255 | 37.98 | 114 |

| Me3TFB-(NH2)2BD | 1624 | 273(295) | 2.7 | 1.12(0.72) | 47 | / | 111 |

| TpPa-NO2 | 398 | 273(298) | 1.5 | 2.38(1.83) | 125.23~34.87 | 36.26 | 115 |

| COF-300-SO3H | 428.42 | 298 | 5.29 | 6.23 | 393 | 39.71 | 116 |

| TMFPT-COF | 1407 | 273 | 1.86 | 1.54 | 19 | 34.1 | 117 |

| TAPT-BP2+-COF | 473.5 | 298 | 3.3 | 1.60 | 51.35 | 34.21 | 118 |

| 3D-TPB-COF-HQ | 842 | 273 | 0.52 | 3.77 | 40 | 23.5 | 119 |

| TBICOF | 1424 | 273(298) | 2.5 | 2.78(1.58) | 40.3 | 42.8 | 120 |

| CTF-TPM | 2002 | 273(298) | 1.13 | 4.84(2.87) | / | 26.9 | 121 |

| NH2-UiO-66@Br-COF | 966 | 273 | 2.5 | 3.86 | 24.08 | 117.2 | 122 |

| Py-CTF-400 | 1515 | 298 | 1.24(1.77) | 4.24 | 76.1 | 25.9 | 107 |

| Py-CTF-500 | 1564 | 298 | 1.24(2.20) | 3.49 | 61.5 | 23.1 | 107 |

| TPP-CTF | 1390 | 273(298) | 1.11 | 9.77(5.02) | 19 | / | 123 |

| 3D-ceq-COF | 1148.6 | 273(298) | 1.0(1.6) | 3.69(2.02) | 27.5 | 50.0 | 124 |

| JUC-568 | 1433 | 273(298) | 1.92 | 3.96(3.27) | / | / | 125 |

图18 (a) 废吸附剂再活化过程[132],(b) 锆稳定氧化钙吸附剂合成及吸附剂循环捕获能力测定[133],(c) MgO-Na2CO3-KNO3吸附剂捕获CO2[139]Fig.18 (a) Reactivation process of spent adsorbent[132],(b) Synthesis of zirconium-stabilized calcium oxide adsorbent and determination of adsorbent cyclic capture capacity[133],(c) CO2 capture by MgO-Na2CO3-KNO3 adsorbent[139] |

图19 (a) UiO-66-NH2与CNF-COOH结合生成复合膜用于CO2/N2分离[144],(b) NCC及氨基-NCC气凝胶制备与应用[145],(c) ZIF-8/PES复合膜结构示意图Fig.19 (a) UiO-66-NH2 combined with CNF-COOH to generate composite membranes for CO2/N2 separation[144],(b) Preparation and application of NCC and amino-NCC aerogels[145],(c) Schematic structure of ZIF-8/PES composite membrane |

表6 各类CO2捕获材料的优缺点Table 6 Advantages and disadvantages of various kinds of CO2 capture materials |

| Materials | Advantages | Disadvantages | Applicability |

|---|---|---|---|

| Amine solution absorbents | High solubility and selectivity;high mass transfer coefficient;stable adsorption in humid environment;the techology is mature | High volatility;high cost;high energy consumption;causing corrosion to equipment | Suitable for most power plants and factories with high CO2 emission concentrations at present |

| ILs | Negligible vapor pressure;high thermal stability;relatively non flammable;strong designability | High viscosity;poor permeability;difficult exposure of active sites | Suitable for environments with high flue gas temperatures |

| Carbon-based adsorbents | High specific surface area;adjustable structure;high thermal stability;low adsorption heat;less affected adsorption performance under humid conditions | Low adsorption capacity;poor adsorption selectivity;high energy consumption during the regeneration process | Can function in low or medium low pressure environments |

| Zeolites based adsorbents | High specific surface area;adjustable pore design;high recyclability at low temperatures;low cost | Low gas selectivity;significant reduction in CO2 adsorption at high temperatures;poor adsorption performance under humid conditions;average regeneration performance | Can function under harsh conditions,such as low temperature environments;suitable for rapid adsorption |

| MOFs | High specific surface area;high CO2 selectivity;large pore volume;high porosity | Poor CO2 adsorption capacity under low pressure conditions;unstable adsorption under humid conditions;poor stability | Suitable for stable environments and appropriately high ambient temperatures |

| COFs | High specific surface area;high thermal and chemical stability;strong functional group adaptability;high CO2 selectivity | Avergy regeneration performance;poor adsorption performance under humid conditions | Suitable for CO2 capture under high pressure;maintaining stability in acidic,alkaline or high-temperature environments |

| Metal oxide sorbents | Superior adsorption effect;low cost of raw materials;synergistic effects can be produced when mixed with other materials | High difficulty of regeneration;average effect of recycling;average thermal stability | Further clarification is needed |

| Biopolymeric nanocomposites | Polymer raw materials are easily available;low energy consumption;strong structural designability;high specific surface area and porosity | Avergy stability and durability;high costs of nanomaterials;poor selectivity | Further clarification is needed |

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

| [74] |

|

| [75] |

|

| [76] |

|

| [77] |

|

| [78] |

|

| [79] |

|

| [80] |

|

| [81] |

|

| [82] |

|

| [83] |

|

| [84] |

|

| [85] |

|

| [86] |

|

| [87] |

|

| [88] |

|

| [89] |

|

| [90] |

|

| [91] |

|

| [92] |

|

| [93] |

|

| [94] |

|

| [95] |

|

| [96] |

|

| [97] |

|

| [98] |

|

| [99] |

|

| [100] |

|

| [101] |

|

| [102] |

|

| [103] |

|

| [104] |

|

| [105] |

|

| [106] |

|

| [107] |

|

| [108] |

|

| [109] |

|

| [110] |

|

| [111] |

|

| [112] |

|

| [113] |

|

| [114] |

|

| [115] |

|

| [116] |

|

| [117] |

|

| [118] |

|

| [119] |

|

| [120] |

|

| [121] |

|

| [122] |

|

| [123] |

|

| [124] |

|

| [125] |

|

| [126] |

|

| [127] |

|

| [128] |

|

| [129] |

|

| [130] |

|

| [131] |

|

| [132] |

|

| [133] |

|

| [134] |

|

| [135] |

|

| [136] |

|

| [137] |

|

| [138] |

|

| [139] |

|

| [140] |

|

| [141] |

|

| [142] |

|

| [143] |

|

| [144] |

|

| [145] |

|

| [146] |

|

| [147] |

|

| [148] |

|

| [149] |

|

| [150] |

|

| [151] |

|

| [152] |

|

| [153] |

|

| [154] |

|

| [155] |

|

/

| 〈 |

|

〉 |