Carbon-Based Electrocatalyst Derived from Porous Organic Polymer in Oxygen Reduction Reaction for Fuel Cells

Received date: 2023-03-31

Revised date: 2023-06-19

Online published: 2023-09-11

Supported by

National Natural Science Foundation of China(22006061)

National Natural Science Foundation of China(21975113)

Gansu Provincial Science Fund for Distinguished Young Scholars(23JRRA808)

Postgraduate “Innovation Star” program of Gansu Province(2023CXZX423)

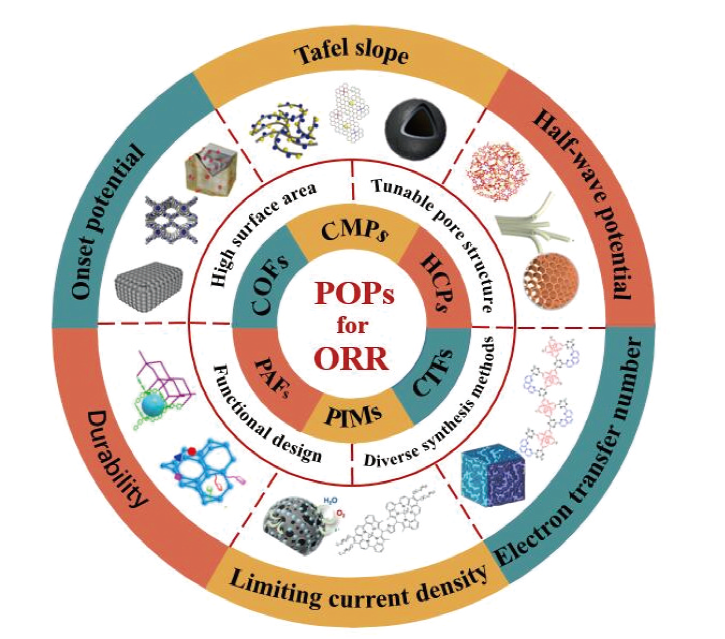

Fuel cell, a kind of energy conversion device that can directly convert chemical energy into electric energy, is a new and an important energy technology during China’s 14th Five-Year Plan. In recent years, the fuel cell technology has undergone iterative upgrading, which effectively promotes the transition of hydrogen energy industry from mode-exploration to multiple demonstration, and helps the high-quality development of the new energy. Cathodic oxygen reduction reaction (ORR) is one of the basic and core reactions of fuel cells, but its slow kinetic process restricts the large-scale application of fuel cells. Although metal Pt-based catalysts have high catalytic activity and can improve the reaction rate of ORR, they are not conducive to wide commercial use because of their scarcity, high cost and poor durability. The development of non-Pt-based ORR catalysts is of great practical significance to promote the development of fuel cells. Porous Organic Polymers (POPs) are an important branch of porous materials. Due to their controllable composition and diverse structure, heteroatoms and metal species can be incorporated into the skeleton to enhance the overall catalytic activity of materials. As ideal candidate materials for electrocatalysts with high-efficiency, POPs have attracted wide attention in promoting the slow kinetics of ORR. In this paper, the research progress in the synthesis strategy, composition, morphology, structure regulation and electrocatalytic performance of POPs-derived carbon-based ORR electrocatalysts in recent years are emphatically introduced. The challenges faced by POPs-derived carbon-based ORR electrocatalysts at present are discussed, and their future development directions are summarized.

1 Introduction

2 Oxygen reduction reaction(ORR)mechanism

3 Design and performance of porous organic polymer derived carbon-based ORR electrocatalysts

3.1 Conjugated microporous polymers(CMPs)derived carbon-based ORR catalysts

3.2 Covalent organic frameworks(COFs)derived carbon-based ORR catalysts

3.3 Hyper-cross-linked polymers(HCPs)derived carbon-based ORR catalysts

3.4 Covalent triazine frameworks(CTFs)derived carbon-based ORR catalysts

3.5 Polymers of intrinsic microporosity(PIMs)derived carbon-based ORR catalysts

3.6 Porous aromatic frameworks(PAFs)derived carbon-based ORR catalysts

4 Conclusion and outlook

Sun Hanxue , Wang Juanjuan , Zhu Zhaoqi , Li An . Carbon-Based Electrocatalyst Derived from Porous Organic Polymer in Oxygen Reduction Reaction for Fuel Cells[J]. Progress in Chemistry, 2023 , 35(11) : 1638 -1654 . DOI: 10.7536/PC230332

图1 (a) 酸性条件下金属表面多电子ORR反应模型[16];(b)酸性条件下N掺杂碳材料ORR反应机理[17]Fig.1 (a) Model of multielectron ORR reaction on metal surface under acid condition[16]. Copyright 1976, Elsevier. (b) ORR reaction mechanism of N-doped carbon materials under acidic conditions[17]. Copyright 2016, American Association for the Advancement of Science |

图2 POPs的典型合成过程和分子结构单元示例Fig.2 Examples of typical synthesis process and molecular structural unit of POPs |

表1 近年来CMPs及其衍生碳基ORR催化剂的电化学性能汇总Table 1 Summary of electrochemical properties of CMPs and their derived carbon-based ORR catalysts |

| Catalysts | Heteroatom | Method for CMPs | Eonset vs.RHE (V) | E1/2 vs.RHE (V) | Jd (mA·cm-2) | Pt/C Jd (mA·cm-2) | Electrolyte | ref |

|---|---|---|---|---|---|---|---|---|

| 1DPC-L3 | B, N, S | Sonogashira-Hagihara coupling reaction | / | 0.75 | 4.6 | 5.3 | 0.1 mol/L KOH | 29 |

| N-HsGDY-900 ℃ | N | Sonogashira-Hagihara coupling reaction | 0.86 | 0.64 | 4.7 | / | 0.1 mol/L HClO4 | 18 |

| 1.02 | 0.85 | 6.5 | / | 0.1 mol/L KOH | ||||

| TPA-BP-1 | N | Sonogashira-Hagihara coupling reaction | 0.80 | / | / | / | 0.1 mol/L KOH | 27 |

| TPA-TPE-2 | 0.82 | / | / | |||||

| ZnPcFePor-CMP | Fe, Zn, N | Sonogashira-Hagihara coupling reaction | 0.902 | 0.724 | -5.31 | / | 0.1 mol/L KOH | 26 |

| FePcZnPor-CMP | 0.936 | 0.866 | -5.59 | |||||

| CPP-P1 | N | Sonogashira-Hagihara coupling reaction | 0.87 | 0.73 | 4.71 | 4.88 | 0.1 mol/L KOH | 30 |

| BP-800 | B, N, Co, Fe | Sonogashira-Hagihara coupling reaction | 0.85 | 0.66 | 5.97 | / | 0.1 mol/L HClO4 | 31 |

| 0.93 | 0.80 | 5.95 | 5.57 | 0.1 mol/L KOH | ||||

| 0.85 | 0.66 | / | / | 0.1 mol/L PBS | ||||

| BPCMP-Fe-800 | Fe, N | Sonogashira-Hagihara coupling reaction | 0.97 | 0.85 | 4.98 | / | 0.1 mol/L KOH | 32 |

| BBCMP-Fe-800 | 0.81 | 0.71 | / | |||||

| C-CMPs-NP | N, S | Sonogashira-Hagihara coupling reaction | 0.98 | 0.82 | 4.2 | 4.3 | 0.1 mol/L KOH | 33 |

| NHCNT-1 | N | Sonogashira-Hagihara coupling reaction | 0.87 | 0.76 | 3.8 | / | 0.1 mol/L KOH | 34 |

| 1.15 | 0.45 | 4.4 | / | 0.1 mol/L HClO4 | ||||

| Fe/N-CMP-1000 | Fe, N | Sonogashira-Hagihara coupling reaction | 0.95 | 0.85 | 5.10 | 4.10 | 0.1 mol/L KOH | 35 |

| CMP-NP-800 | N | Sonogashira-Hagihara coupling reaction | 0.903 | 0.815 | / | 4.25 | 0.1 mol/L KOH | 36 |

| CMP-NP-900 | 0.930 | 0.857 | 4.45 | |||||

| CMP-NP-1000 | 0.872 | 0.766 | / | |||||

| N-Fc-800 | Fe, N | Schiff base reaction | 0.96 | 0.82 | 5.3 | 4.6 | 0.1 mol/L KOH | 37 |

| CoNCs800 | Co, N | Schiff base reaction | 0.905 | 0.807 | -4.72 | / | 0.1 mol/L KOH | 38 |

| 0.80 | 0.70 | -4.40 | 3.57 | 0.5 mol/L H2SO4 | ||||

| CoPP-FePc-CMPs | Co, Fe, N | Schiff base reaction | 0.837 | 0.426 | 1.537 | 5.85 | 0.1 mol/L KOH | 39 |

| CoFeNC | 0.904 | 0.775 | 3.68 | |||||

| CoFeNG | 0.957 | 0.777 | 4.00 | |||||

| C-POP-2-900 | N, P | Schiff base reaction | -0.11 | -0.19 | / | / | 0.1 mol/L KOH | 40 |

| Fe/Co-CMP-800 | N, Fe, Co | Suzuki coupling reaction | 0.88 | 0.78 | 4.5 | / | 0.5 mol/L H2SO4 | 41 |

| TT-TPB | S | Suzuki coupling reaction | 0.9 | 0.89 | / | / | 0.1 mol/L KOH | 28 |

| TPP-CMP-900 | N | Suzuki coupling reaction | 0.95 | 0.83 | 4.05 | 4.1 | 0.1 mol/L KOH | 42 |

| XWB-CMP-1000 | N, S | one-pot catalyst-free procedure | -0.11 | -0.19 | -5.2 | / | 0.1 mol/L KOH | 43 |

| CoO/ZnO@N-PC | Co, Zn, N | Molten salt-templated approach | 0.91 | 0.85 | / | / | 0.1 mol/L KOH | 44 |

| N, P-CMP-1000 | N, P | Acid-catalyzed con- densation | 0.94 | 0.84 | / | / | 0.1 mol/L KOH | 45 |

| 0.75 | 0.57 | / | / | 0.1 mol/L HClO4 | ||||

| / | 0.48 | / | / | 0.01 mol/L PBS |

图7 (a)在ZIF-67表面配合生长TP-BPY-COF合成COF@ZIF800催化剂的工艺示意图。(b) TP-BPY-COF的合成与结构。ZIF-67 (c)、COF@ZIF (d)、COF@ZIF800 (e)的SEM图像[64]Fig.7 (a) Schematic of the synthesis procedure of COF@ZIF800 catalyst by in-situ growing TP-BPY-COF on the surface of ZIF-67. (b) The synthesis and structure of TP-BPY-COF. The SEM images of ZIF-67 (c), COF@ZIF (d), and COF@ZIF800 (e)[64]. Copyright 2022, Royal Society of Chemistry |

表2 基于外部交联剂编织法的HCPs衍生碳基ORR催化剂的电化学性能汇总Table 2 Summary of electrochemical properties of HCPs derived carbon-based ORR catalysts |

| Catalysts | Heteroatom | Monomer | Eonset vs. RHE (V) | E1/2 vs. RHE (V) | Jd (mA·cm-2) | Pt/C Jd (mA·cm-2) | Electrolyte | ref | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N-PHCP-900 | N | Pitch | / | 0.883 | / | / | 0.1 mol/L KOH | 76 | ||||||||||

| Fe/HCPs | Fe | Zeolitic imidazolate frameworks | 0.960 | 0.850 | 5.59 | 5.73 | 0.1 mol/L KOH | 77 | ||||||||||

| Fe/HCPs-etching | 0.900 | 0.799 | 4.96 | |||||||||||||||

| TPP-HCP-1 | Fe, N | 5,10,15,20-tetrakis (4-chlorophenyl) porphyrin | 0.96 | 0.85 | 4.00 | 3.9 | 0.1 mol/L KOH | 78 | ||||||||||

| MPH-Fe/C | Fe, N | metalloporphyrin | / | 0.816 | / | / | 0.1 mol/L KOH | 74 | ||||||||||

| PCF-HCP-900 | Fe, N | Pyrrole | 0.95 | 0.84 | 4.8 | 5.2 | 0.1 mol/L KOH | 72 | ||||||||||

| NCP-An-900 | Fe, N | Aniline, pyrrole, methylbenzene | 0.96 | 0.85 | -5.31 | -5.20 | 0.1 mol/L KOH | 70 | ||||||||||

| Co-TSP-HCP-900 | Co, N | Carbazole | 0.90 | 0.80 | 4.75 | 4.3 | 0.1 mol/L KOH | 73 | ||||||||||

| Fe-TSP-HCP-900 | Fe, N | 0.89 | 0.76 | 4.50 | ||||||||||||||

| PPFeC-800 | Fe, N | Pyrrole, thiophene | 0.977 | 0.833 | 5.15 | / | 0.1 mol/L KOH | 71 | ||||||||||

| PTFeC-800 | Fe,S | 0.942 | 0.825 | 5.17 | ||||||||||||||

| MixFeC-800 | Fe, N, S | 0.983 | 0.844 | 5.07 | ||||||||||||||

| HCP-NSZn-900 | Fe, N, S | Triazine derivative | 0.98 | 0.86 | 4.72 | 4.59 | 0.1 mol/L KOH | 75 | ||||||||||

| 0.85 | 0.68 | / | / | 0.1 mol/L HClO4 | ||||||||||||||

| FeCoP/NPC | Fe, Co, N | Poly(bis(N-carbazolyl)-1,2,4,5-tetrazine) | 0.948 | 0.855 | 5.23 | / | 0.1 mol/L KOH | 79 | ||||||||||

| HCP-NT-NH3-800 | O, S | Hexakis(benzylthoi) benzene, thiophene | 1.01 | 0.85 | 4.99 | / | 0.1 mol/L KOH | 80 | ||||||||||

表3 CTFs衍生碳基ORR催化剂的电化学性能汇总Table 3 Summary of electrochemical properties of CTFs derived carbon-based ORR catalysts |

| Catalysts | Heteroatom | Method | Eonset vs. RHE (V) | vs. RHE (V) | Jd (mA·cm-2) | Electrolyte | ref |

|---|---|---|---|---|---|---|---|

| NHC/rGO-950 | N | Situ “bottom-up” trimerization | 0.95 | 0.83 | -5.64 | 0.1 mol/L KOH | 87 |

| N-HCNFs-2-1000 | N | Step-wise polymerization | 1.01 | 0.84 | 5.56 | 0.1 mol/L KOH | 89 |

| CTF-CSU1 | N | Bottom-up technology | 0.79 | 0.57 | 5.6 | 0.1 mol/L KOH | 90 |

| CTF-Super P-10 | N | Ionothermal synthesis | 0.981 | 0.883 | 5.31 | 0.1 mol/L KOH | 86 |

| 0.840 | 0.717 | 5.40 | 0.1 mol/L HClO4 | ||||

| BINOL-CTF-10-500 | N | Ionothermal synthesis | 0.793 | 0.737 | / | 0.1 mol/L KOH | 91 |

| BINOL-CTF-5-400 | 0.758 | 0.684 | / | ||||

| BINOL-CTF-5-500 | 0.760 | 0.688 | / | ||||

| BINOL-CTF-10-400 | 0.737 | 0.659 | / | ||||

| DCBP-750 | N | Ionothermal synthesis | 0.90 | 0.79 | -5.1 | 0.1 mol/L KOH | 92 |

| PDCB-750 | 0.88 | 0.75 | -6.2 | ||||

| PDCB-600 | 0.84 | 0.68 | -6.6 | ||||

| PDCB-400 | 0.65 | / | -2.0 | ||||

| PDCB | 0.84 | 0.68 | -6.6 | ||||

| DCBP | 0.85 | 0.71 | -6.3 | ||||

| FB7 | Fe, N | Ionothermal synthesis | 0.871 | 0.757 | / | 0.1 mol/L HClO4 | 93 |

| Fe-C3N3-750 | Step-wise polymerization subse, quent pyrolysis, NH3 activation | 0.956 | 0.794 | 4.75 | 0.1 mol/L KOH | 85 | |

| Fe-C3N3-750-NH3 | 1.03 | 0.840 | 4.82 | ||||

| TEBCB-Fe-N/S/C | Fe, N, S | Post-polymerization | 0.899 | 0.79 | / | 0.1 mol/L HClO4 | 94 |

| Cu-CTF/CP | Cu, N | Hybridization | 0.81 | / | / | Phosphate buffer solution | 95 |

| Co-CTF/KB | Co, N | Ketjen Black hybridization | / | 0.83 | 6.14 | 0.1 mol/L KOH | 96 |

| NPF-CNS-2 | N, P, F | Self-templated carbonization strategy | 0.90 | 0.81 | 5.42 | 0.1 mol/L KOH | 97 |

| 0.82 | 0.69 | 5.01 | 0.1 mol/L HClO4 | ||||

| 0.83 | 0.70 | 5.03 | 0.5 mol/L H2SO4 | ||||

| 0.70 | 0.58 | 4.23 | 0.1 mol/L PBS |

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|

| [73] |

|

| [74] |

|

| [75] |

|

| [76] |

|

| [77] |

|

| [78] |

|

| [79] |

|

| [80] |

|

| [81] |

|

| [82] |

|

| [83] |

|

| [84] |

|

| [85] |

|

| [86] |

|

| [87] |

|

| [88] |

|

| [89] |

|

| [90] |

|

| [91] |

|

| [92] |

|

| [93] |

|

| [94] |

|

| [95] |

|

| [96] |

|

| [97] |

|

| [98] |

|

| [99] |

|

| [100] |

|

| [101] |

|

| [102] |

|

| [103] |

|

| [104] |

|

| [105] |

|

| [106] |

|

| [107] |

|

| [108] |

|

/

| 〈 |

|

〉 |